Carbon nanotube products

Packaging

Jar 0.4 L (up to 100 g)

Other packaging volumes are available at customers’ request

Conductive additive based on a plasticizer with a stabilizing agent for solvent-based epoxy and PU coatings without drawbacks in color and mechanical properties.

The price of our nanotube products is determined by the quantity. Reach out to us for a personalized offer.

Material system

Solvent-based epoxy and polyurethane resins

Working dosage

0.1–1 wt.%

Сoncentrate carrier

Plasticizer & stabilizing agent – fatty acid glycidyl ester, ammonium salt of polyolefins-based derivative

Shape

Paste

Benefits

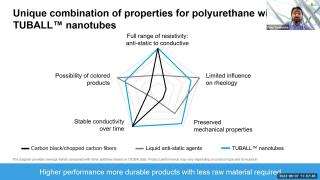

Electrical conductivity

Ensures permanent and uniform conductivity without “hot spots”

Mechanical properties

Maintains or even increases mechanical strength

Color retain

Allows retention of bright and light colors of materials

Easy to use

The form of concentrate greatly simplifies the handling of nanotubes without additional changes to standard manufacturing process

Viscosity Retain

Minimises the impact on viscosity and density of the host material

Cases

Lining Coating

click to view case

Tank coating

click to view case

Video

TUBALL MATRIX — Processing Guidelines

Documents

Also available in:

English

TDS TUBALL MATRIX 203 ENG V07.PDF

PDF204.8 kB

TUBALL MATRIX 200X 300X PROCESSING GUIDELINES ENG V03.PDF

PDF614.4 kB

News

October 27

[#DidYouKnow?] 💡 “Sludge” refers to various sediments like lime, corrosion, and more found in oil and gas pipelines. On long pipelines, this sludge can accumulate, weighing hundreds of kilograms. Pipeline inspection gauges (#PIGs) help efficiently remove this sludge and liquids from natural gas lines. To enhance safety and prevent accidents, graphene nanotubes are added to polyurethane ball pigs, ensuring anti-static properties without compromising mechanical durability.

Learn more on anti-static additive for conductive polyurethane: https://tuball.com/nanotubes-in/polyurethane?utm_source=Facebook&utm_medium=POst+campaign&utm_campaign=Oct+27

#PU #polyurethane #oilandgas #composites

Read on Facebook

July 11

Does adding conductivity to PU rollers and sleeves lead to additional expense for the manufacturing process? Not always! Watch this webinar recording and differentiate yourself from competitors by manufacturing conductive, high-performance rollers and sleeves without complicating your production: https://youtu.be/gVhqivUYAYM

Request a sample: https://tuball.com/nanotubes-in/polyurethane?utm_source=Facebook+TPS&utm_campaign=Webinar+on+PU+rollers%26sleevesShort1

#Polyurethane #ConductiveAgent #GrapheneNanotubes

Read on Facebook

June 21

PU rollers with graphene nanotubes to enhance efficiency and safety are made by US-based company I.B. Moore. Nanotubes add conductivity, preventing damage to electronic products cause by triboelectric charging. This innovation provides cost savings in a sustainable approach by reducing the need for standard anti-static agents. The advanced rollers are highly welcomed in the printing, packaging, and automation sectors.

Read the article here: https://ocsial.com/news/us-innovation-pu-rollers-offering-increased-efficiency-and-occupational-safety---thanks-to-graphene-nanotubes/

Learn more on our anti-static agent for polyurethane: https://tuball.com/nanotubes-in/polyurethane?utm_source=Facebook&utm_campaign=PU+rollers+press-release+

#PU #rollers #composites

Read on Facebook