Conductive additive based on a surfactant for solvent-free epoxy and PU coatings without drawbacks in color and mechanical properties. Also recommended for epoxy composites.

The cost of our SWCNT products depends on the quantity ordered. Please reach out to us for a personalized quote.

Benefits

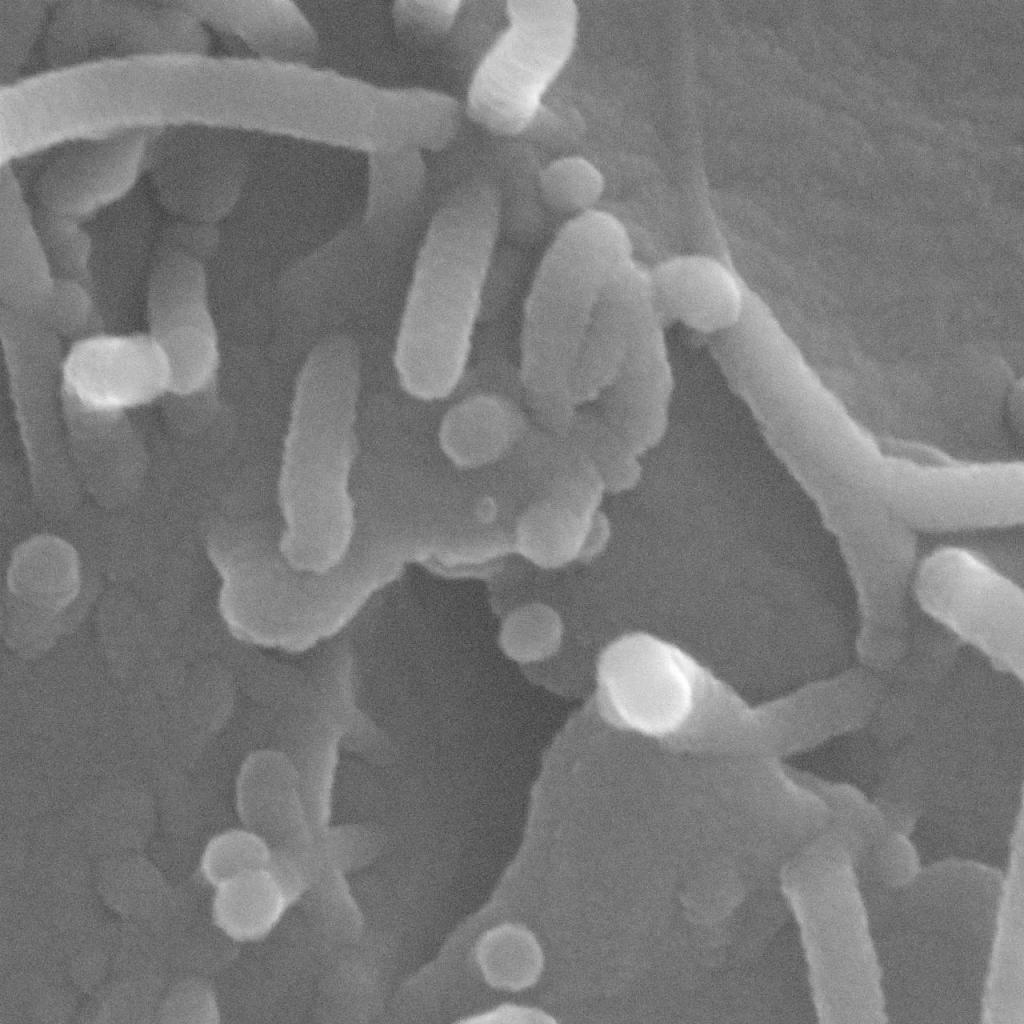

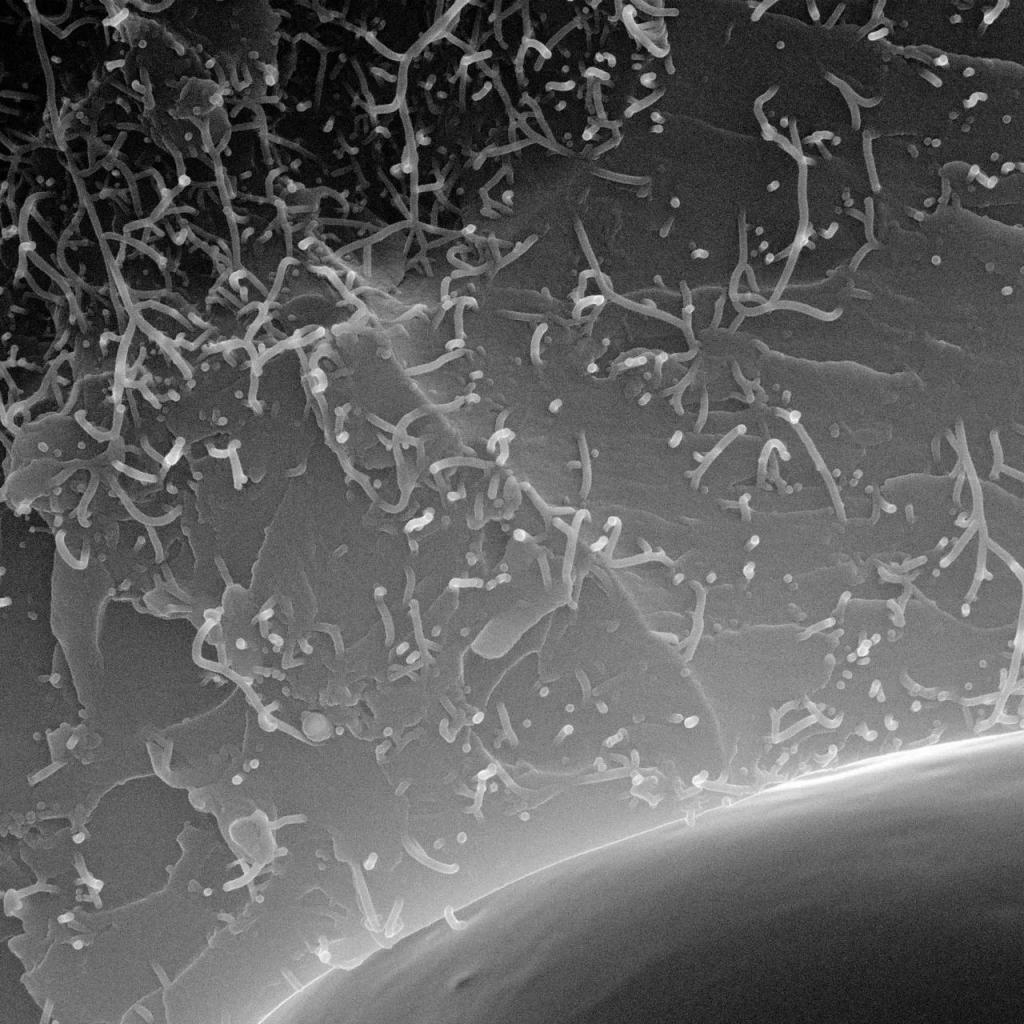

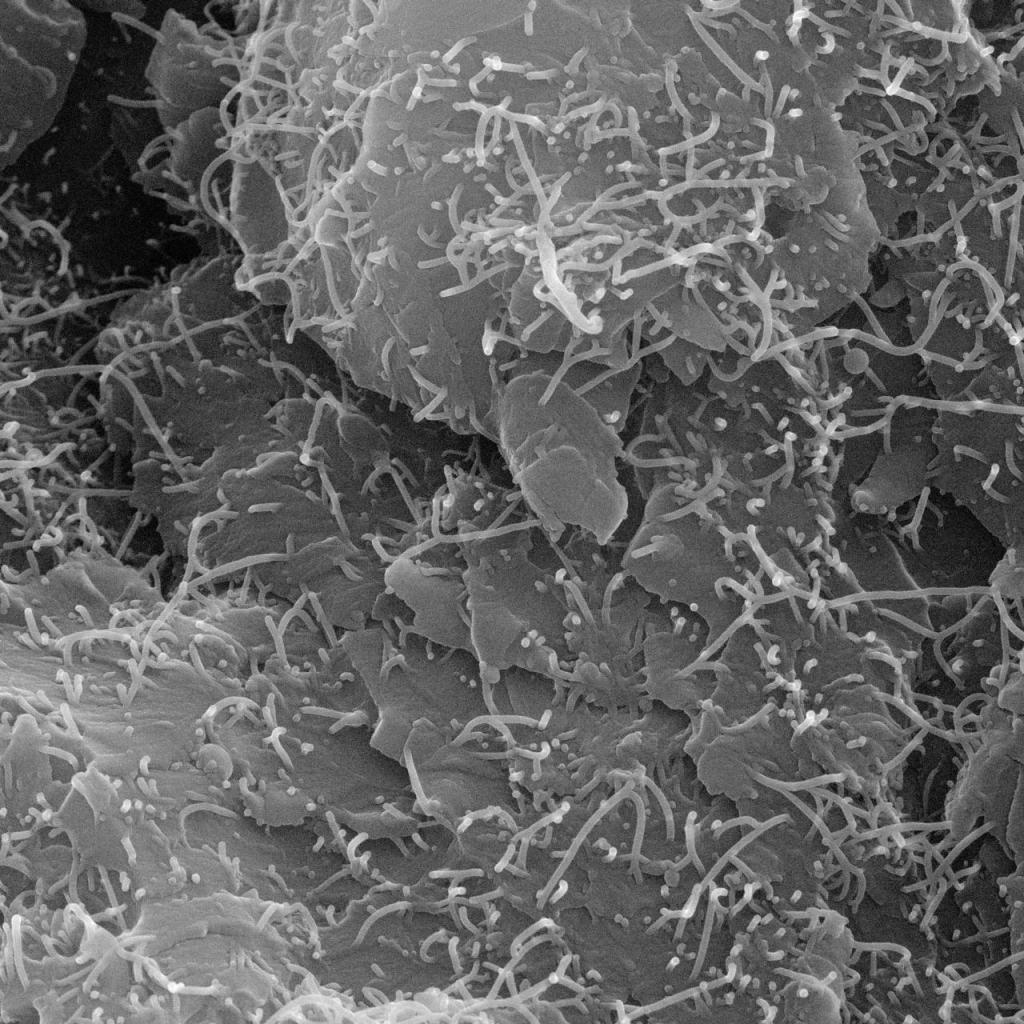

Allows uniform and permanent electrical conductivity without “hot spots”

Anti-static properties independent of humidity

Maintains or even increases mechanical properties

Adding color to epoxy and polyurethane resins is possible due to low working dosages of the concentrate and minimal greying effect

Minimally affects density, viscosity and other rheological properties of matrix material

The pre-dispersed formula allows use of standard manufacturing equipment

Cases

Anti-static topcoat for rotor sails

Epoxy Floor

GFRP Pipes

Video

TUBALL MATRIX — Processing Guidelines

Anti-static and conductive hand layup composites: how to produce using graphene nanotubes

Documents

News