Carbon nanotube products

Packaging

Jar 0.6 L (up to 250 g)

Other packaging volumes are available at customers’ request

Silicone Rubber

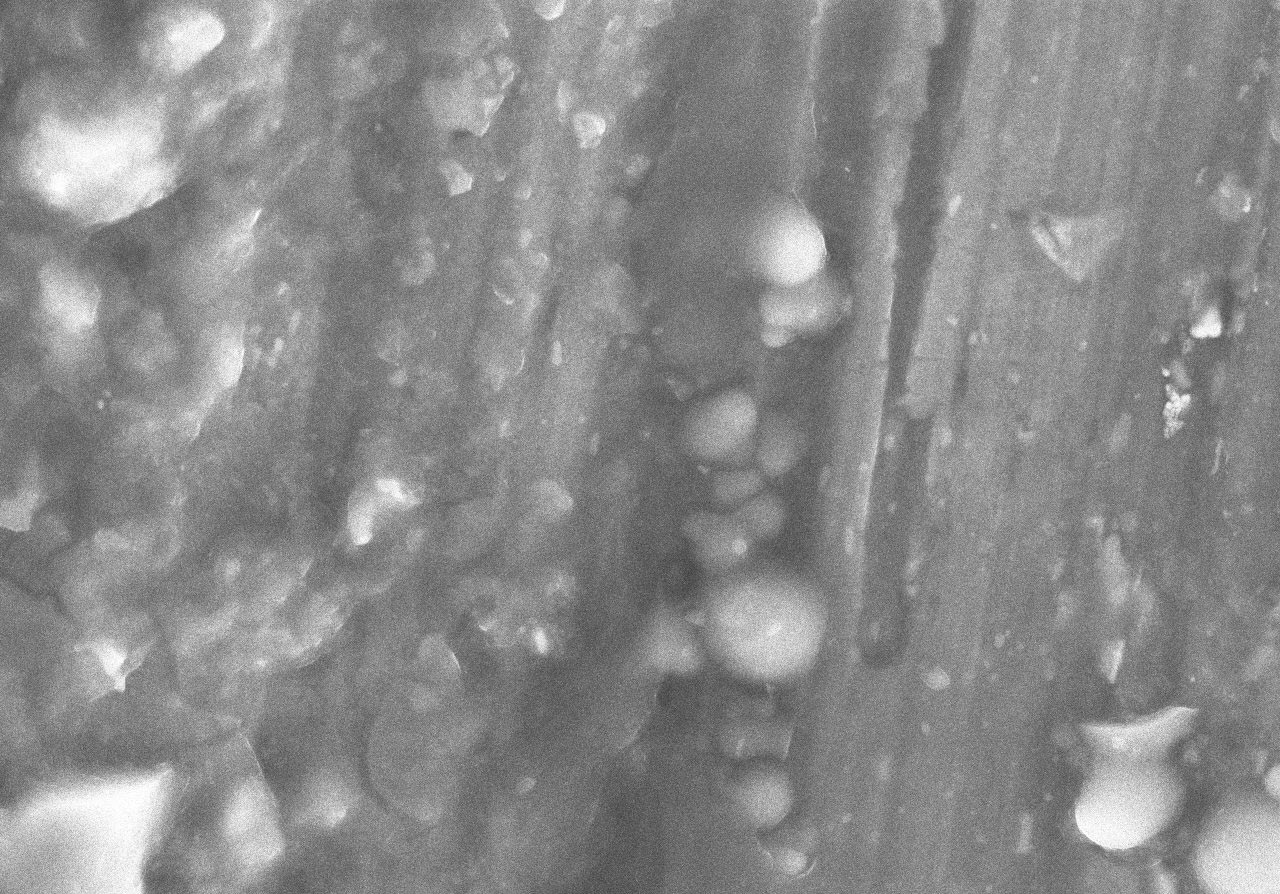

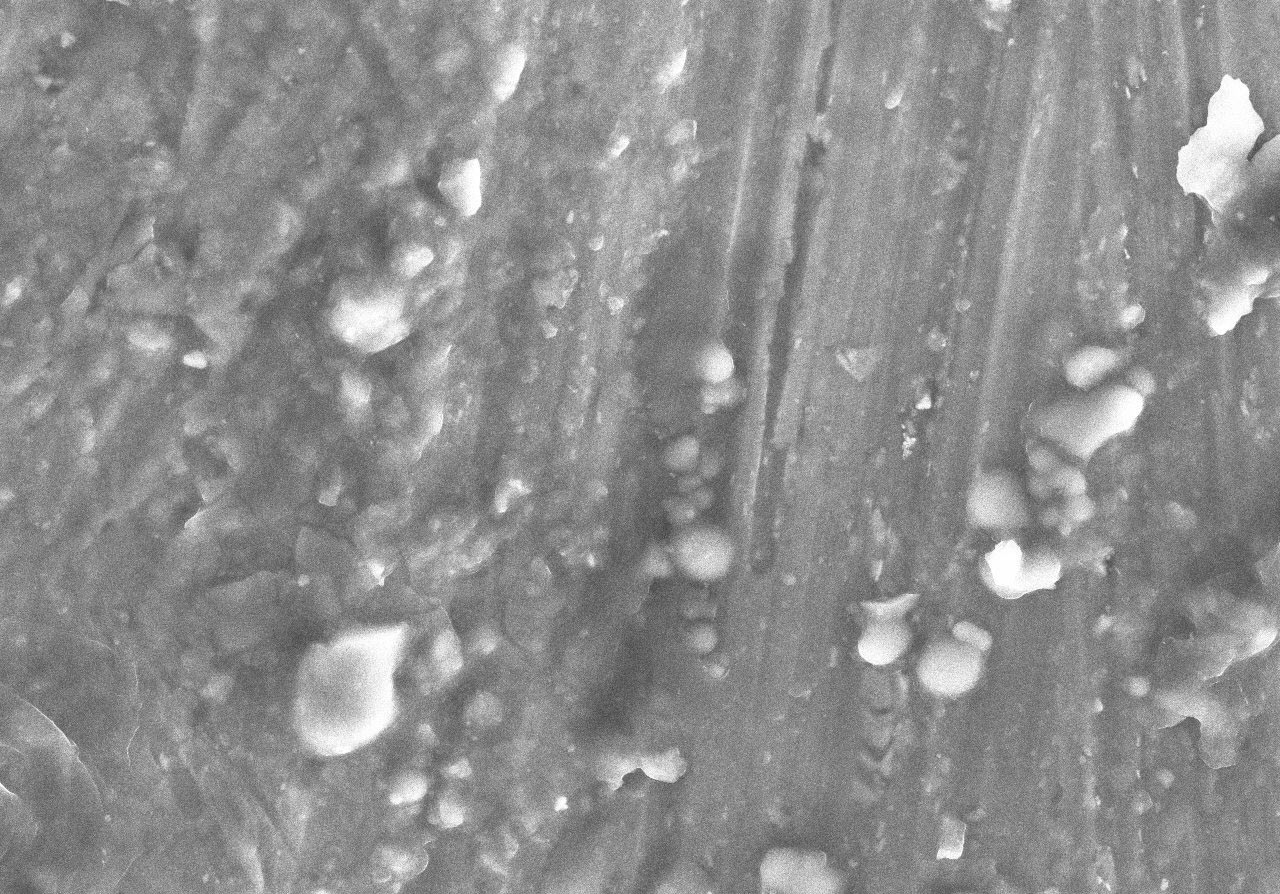

TUBALL™ MATRIX 602, a graphene nanotube-formulated super-concentrate based on crosslinking carrier for liquid silicone rubbers (LSR), room temperature vulcanised rubber (RTV) and high consistency rubbers (HCR), was specifically developed to improve nanotube usability by providing a fine dispersion of nanotubes in the host matrix while maintaining softness.

The cost of our SWCNT products depends on the quantity ordered. Please reach out to us for a personalized quote.

Material system

LSR, RTV, HCR

Working dosage

0.3–5 wt.%

Сoncentrate carrier

Vinyl-terminated polydimethylsiloxane

Shape

Paste

Benefits

Electrical conductivity

Ensures independent of humidity permanent and uniform conductivity without “hot spots”

Retains color

- Allows retention of color

- No carbon release at the surface

Maintains mechanical properties

Minimises the impact on compound elasticity and tensile parameters, viscosity and rheological properties

Easy to use

Allows use of standard processing and mixing equipment

Cases

Touchscreen-compatible silicone finger prostheses

click to view case

Documents

Also available in:

English

TDS TUBALL MATRIX 602 ENG V07.PDF

PDF409.6 kB

TUBALL MATRIX 601 602 PROCESSING KEY POINTS ENG V01.PDF

PDF102.4 kB

TUBALL MATRIX 601 602 613 BETA PROCESSING GUIDELINES ENG V06.PDF

PDF1.2 MB

News

January 31

[#DidYouKnow❓] A pressure-sensitive adhesive (#PSA) is a material that creates a bond between two surfaces through surface contact, accelerated by external pressure. In electronic products, PSAs are crucial for bonding plastic or metal substrates and attaching glass displays on polymer substrates. 📱 Graphene nanotubes offer a sought-after combination of consistent electrical conductivity, stability at high temperatures, high transparency, and a smooth, uniform surface for PSAs, surpassing the traditional conductive agents used in industry. ✅

Learn more on graphene nanotubes for anti-static silicone PSA: https://tuball.com/nanotubes-for/silicone-psa?utm_source=Facebook&utm_medium=Did+you+know_PSA&utm_campaign=Jan+31%272024

#silicone #adhesivesolutions #conductive

Read on Facebook

December 6

[Breaking news] 🚀 Discover the revolutionary technology of ultrathin, permanently conductive PSA with graphene nanotubes. Achieve remarkable transparency and reduce the number of layers in protective films. Dive into the next-gen film technology for electronics, medical devices, automotive applications, and packaging! 🌐

Read the news in full: https://ocsial.com/news/graphene-nanotubes-revolutionize-protective-film-technology-ultrathin-permanently-conductive-psa/

Learn more on nanotubes for anti-static silicone PSA: https://tuball.com/nanotubes-for/silicone-psa?utm_source=Facebook&utm_medium=PSA+film+press-release&utm_campaign=Dec+06

#PSA #film #adhesives #silicone

Read on Facebook

June 20

From a dosage of just 0.04%, graphene nanotubes make silicone an ideal skin-contact material for healthcare and wearable devices. 3D conductive reinforcing networks inside the rubber allow you to combine elasticity, softness, and conductivity with no skin contamination. This is unachievable with other additives. Request a sample at https://tuball.com/nanotubes-for/conductive-silicones?utm_source=FacebookPS&utm_campaign=SiliconeWearablesTPS

#SiliconeRubber #GrapheneNanotubes #Wearables #ElectricalConductivity

Read on Facebook