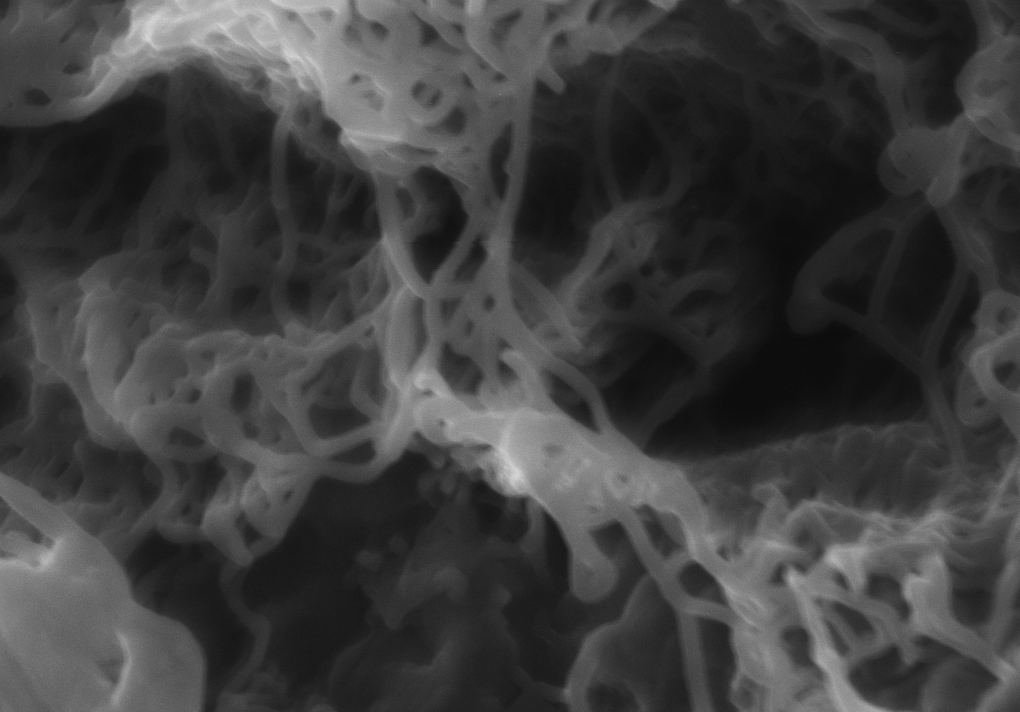

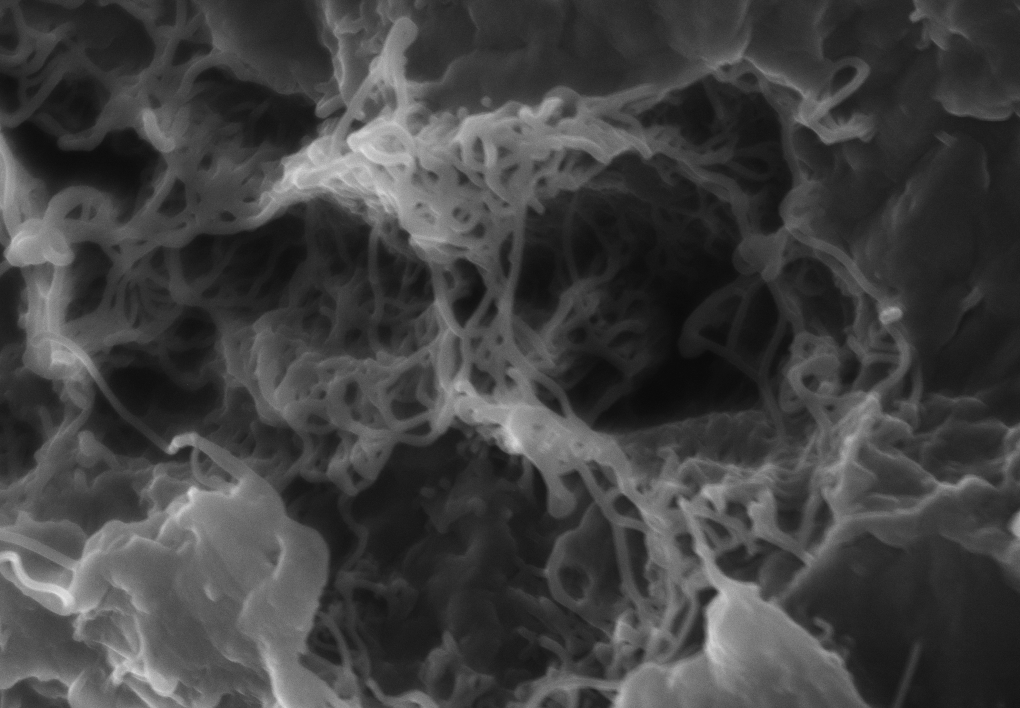

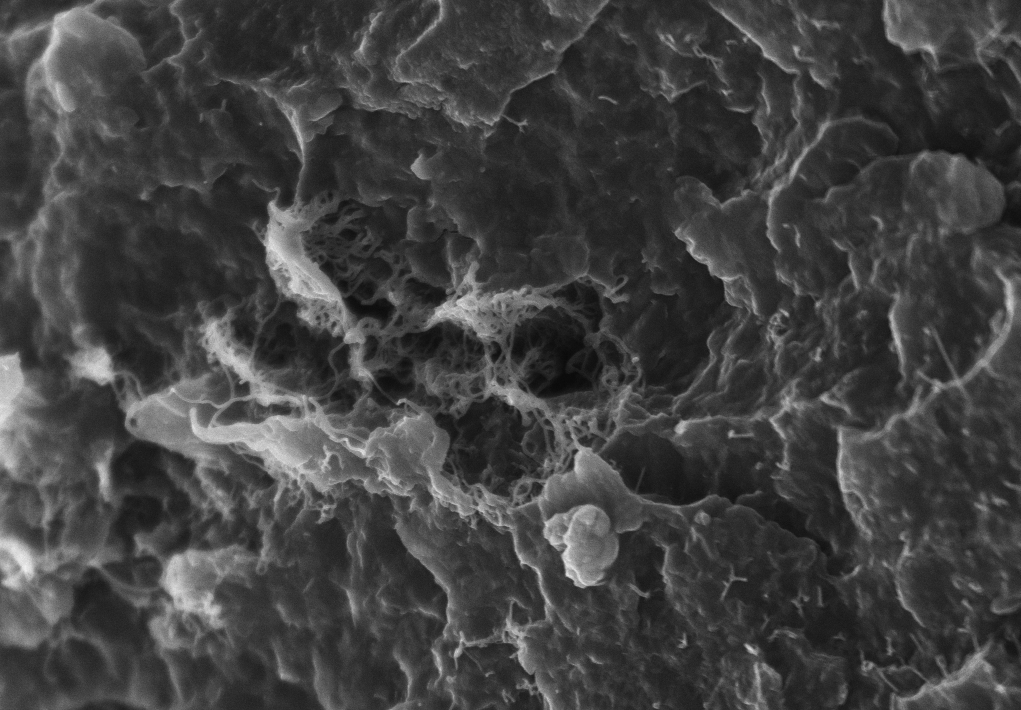

Carbon nanotube products

Packaging

Tegla 0.6 L (up to 500 g)

Ostala pakovanja dostupna na zahtev korisnika

Svestrani provodni aditiv za proizvodnju termo-plastičnog poliuretana (TPU), punjenog fenil polisulfida (PPS) akrilonitril-butadien-stirena (ABS), polikarbonata (PC), PC-ABS, poliamida (PA), poliamid smole ojačane staklenim vlaknima (GF PA).

Kontaktirajte nas za kupovinu proizvoda od nanocevi. Cena zavisi od količine.

Sistem materijala

Termo-plastični poliuretana (TPU), punjeni fenil polisulfida (PPS) akrilonitril-butadien-stiren (ABS), polikarbonat (PC), PC-ABS, poliamid (PA), poliamid smola ojačana staklenim vlaknima (GF PA)

Radna doza

0.5–5 wt.%

Nosač koncentrata

Poliol ester

Oblik

Pellets

Benefits

Električna provodljivost

Trajna i homogena električna provodljivost pri niskim dozama

Mehaničke karakteristike

Zadržavanje originalnih ključnih mehaničkih performansi

Trajne karakteristike

Otpornost ne zavisi od vlage

Manje odbitaka

Manje odbačenih finalnih delova

Cases

Signalni lampi

kliknite da biste videli slučaj

Documents

Takođe dostupan u:

English

TDS TUBALL MATRIX 808 ENG V12.PDF

PDF204.8 kB

TUBALL MATRIX 808 ABS PROCESSING GUIDELINES ENG V04.PDF

PDF204.8 kB

TUBALL MATRIX 808 GF PA6 PA6.6 PROCESSING GUIDE ENG V04.PDF

PDF204.8 kB

Video

How to grant conductivity to glass fiber reinforced polyamide: compounding guide