Carbon nanotube products

Packaging

Jerrycan 1 L

Other packaging volumes are available at customers’ request

Cathode

TUBALLBATT NMP

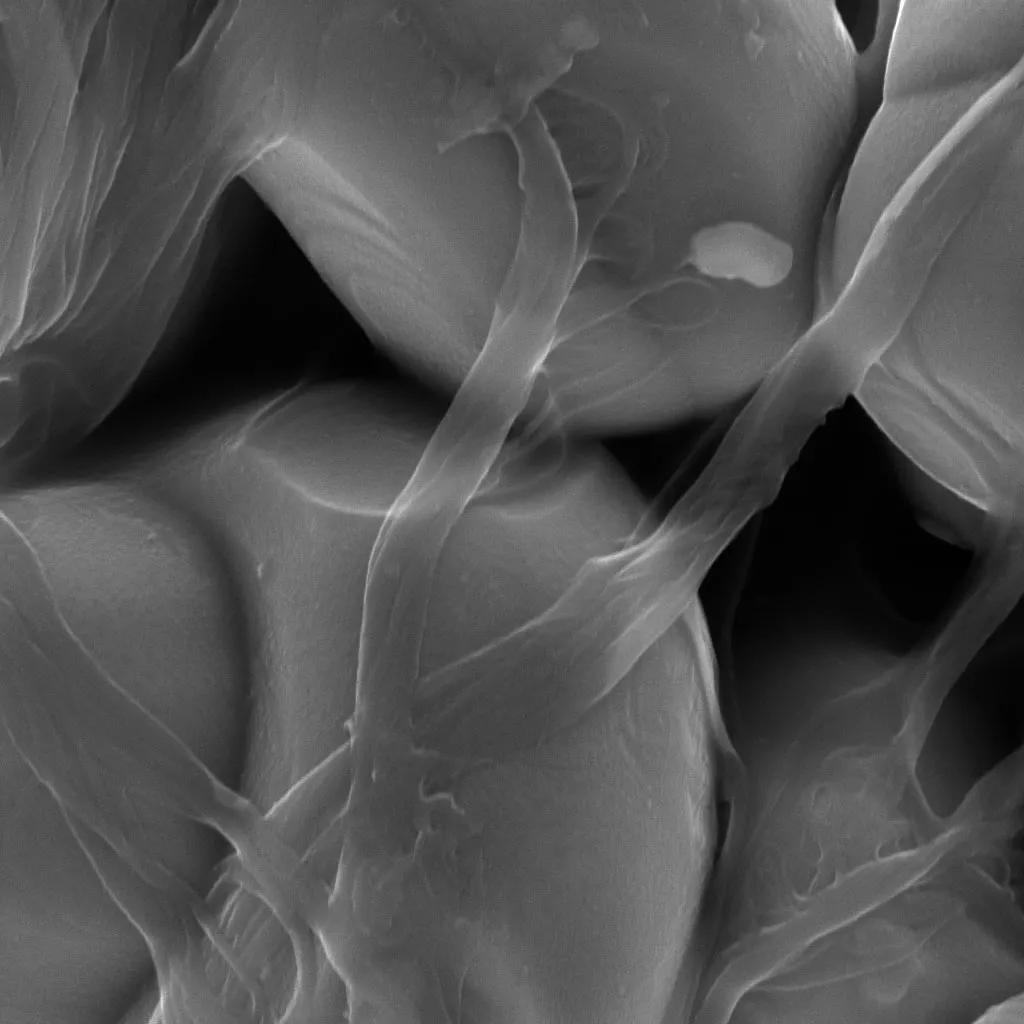

TUBALL™ BATT NMP is an ultrafine TUBALL™ nanotube dispersion in NMP for high-energy cathodes. TUBALL’s unmatched conductivity enables improved battery safety and energy density. TUBALL™ BATT is now available in an optimized, more cost-efficient dispersion form.

To buy nanotube products, please contact us. Price depends on the required volumes.

Material system

High energy cathodes (ex. NCM 811, NCM 622, NCM 523, NCA, LCO, LFP)

Сoncentrate carrier

NMP, PVDF, others

Shape

Suspension

Benefits

Boosted energy density

Thanks to 10–60 times lower loading of conductive additive, up to 98.8% active material content possible in dry electrode

Higher safety

Increased safety due to halved battery resistance increase (DCR)

Higher discharge power

>50% higher at high discharge rates

Improved adhesion

Doubled thanks to the bond strength between cathode particles

Documents

Also available in:

English

TDS TUBALL BATT NMP 0.4% 02NM23 ENG V06.PDF

PDF102.4 kB

TDS TUBALL BATT NMP 1% 02NM29 ENG V03.PDF

PDF102.4 kB

News

March 20

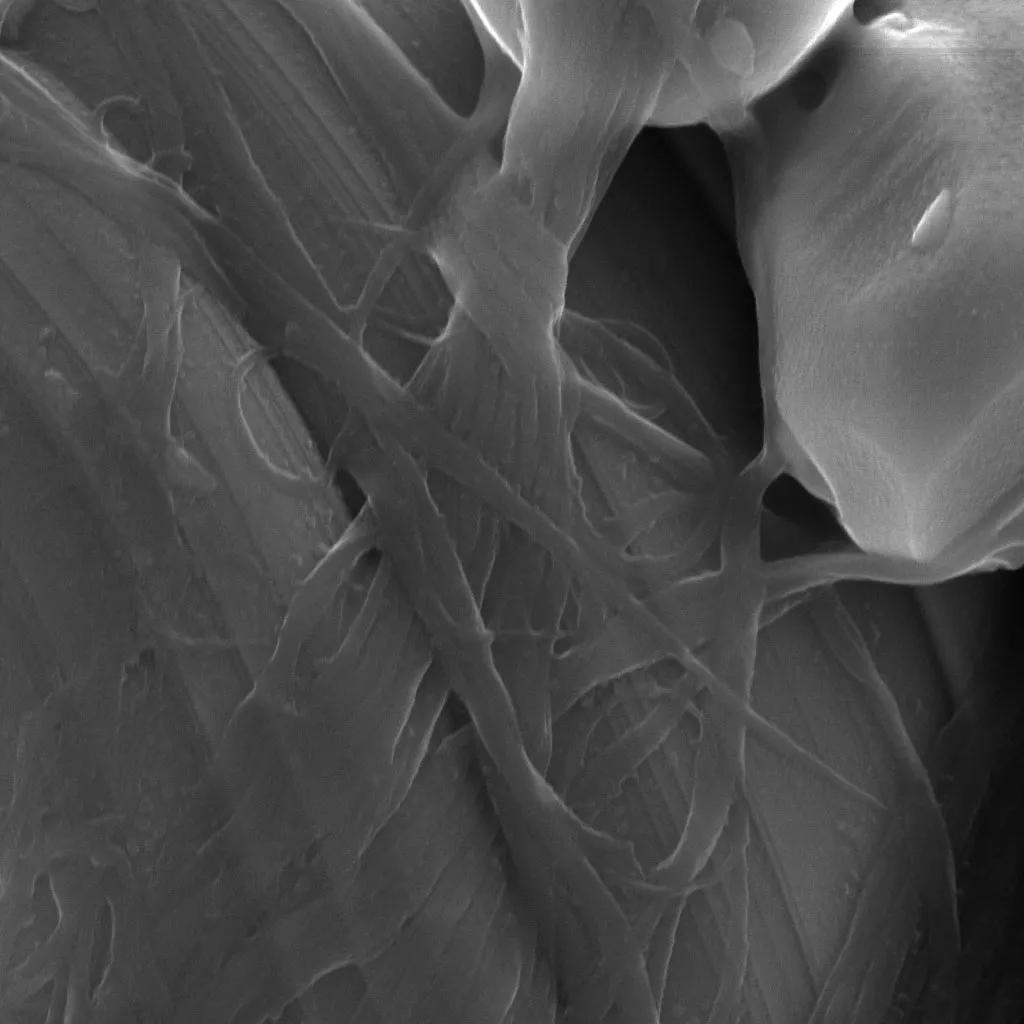

At the 8th International Forum on Cathode & Anode Materials for Advanced Batteries (ABCA-8), Sun Chao, OCSiAl’s sales manager explained the pivotal role of single wall carbon nanotubes in high-performance batteries. TUBALL™ nanotubes in thick LFP electrodes not only enhance conductivity but also improve the mechanical properties of the electrode, preventing cracking.

Read the full news on our Weixin page: https://mp.weixin.qq.com/s/SPGboug2xhqbKbVJmiDDBg?poc_token=HKAK9GWjAXOBTtDDEPZPzixT8TbEdxvaaaRdtHvo

Learn more on TUBALL™: https://tuball.com/?utm_source=Facebook&utm_medium=ABCA-8+onsite+photo&utm_campaign=March+20%272024

#batteries #LFP #electrode #conference

Read on Facebook

November 14

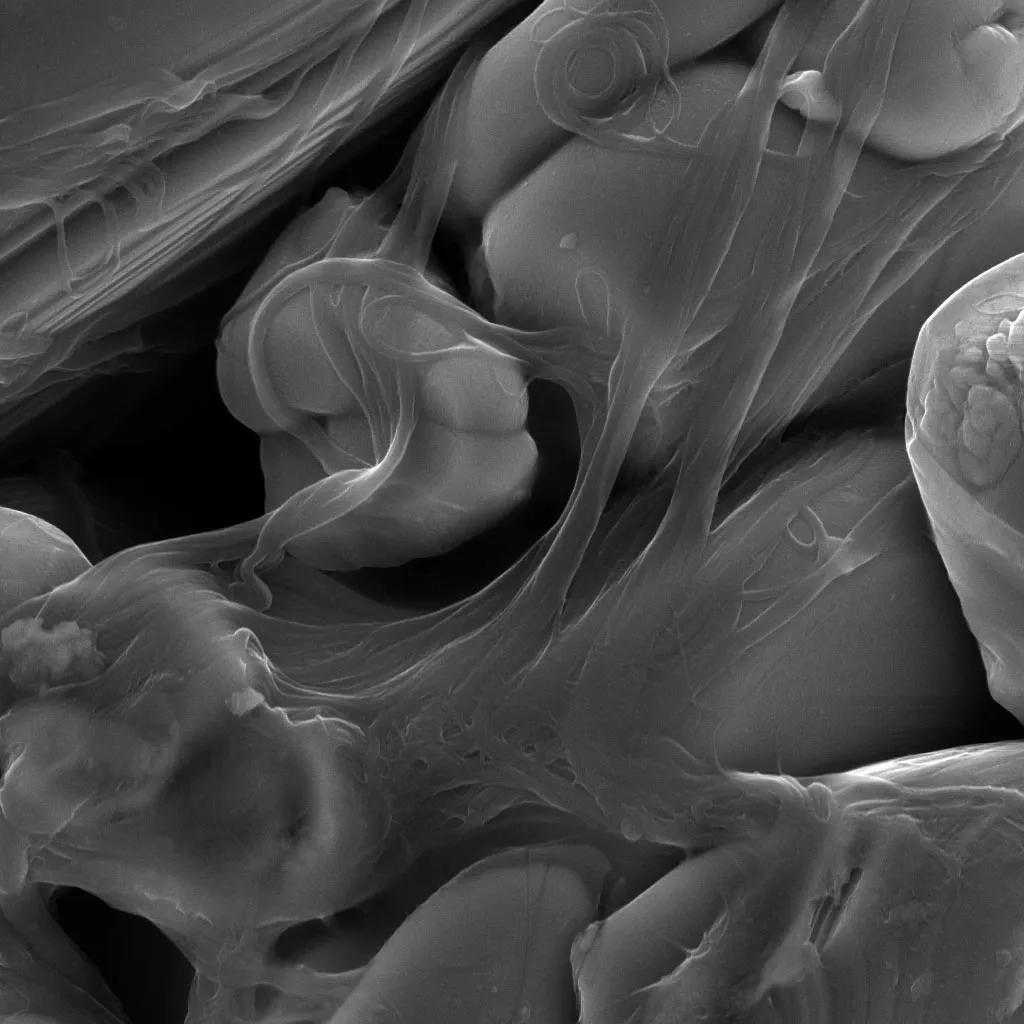

Join our webinar on December 5 and gain the latest technical insights on SWCNTs in today’s trending battery technologies. Nanotubes pave the way to long-lasting, silicon-rich (SiOx and SiC) anodes, enable record-thick LFP cathodes for energy storage systems (ESS) and EVs, make it possible to improve the tensile strength and reduce the amount of PTFE in this emerging tech, improve battery cycle life, and lower internal resistance, enabling high-performing electrodes, fast-charging graphite, and single-crystal NCM materials.

Register via the link:

https://events.zoom.us/ev/AsJM4aDgmkugi1bR5OFlW9jPyR92HdeOIMqzi5262YDKXEdDd-yY~ArXTE2RAoIF4YVW0EQis7V2Izp2uj8cK477DYBQAk7rDpL_OOCdeJ4LyYowcwinmRAfWiW8WJdtGvSSxUMkQACiPvQ

Learn more about nanotubes in batteries: https://tuball.com/nanotubes-for/high-performance-ev-batteries?utm_source=facebook&utm_medium=Battery+announcement+%232&utm_campaign=Nov+14%272023

#freewebinar #batteries #EV

Read on Facebook

October 19

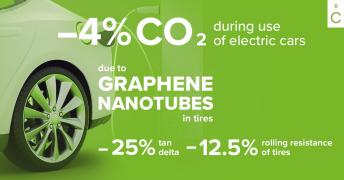

Graphene nanotubes in tire treads can reduce emissions from EV usage by 2–4%. How? Nanotubes add conductivity and make it possible to alter formulations to retain high elasticity in tire treads. This decreases tan delta at 60°C by 15–25%, consequently reducing the rolling resistance coefficient by about 7–12%. Ultimately, this results in 2–4% less emissions during EV usage.

Learn more on graphene nanotubes for elastomers: https://tuball.com/nanotubes-in/elastomers?utm_source=Facebook&utm_medium=GNT+emission+banner&utm_campaign=post+campaign_Oct+19

#EV #tires #emissions #sustainability

Read on Facebook