Carbon nanotube products

Emballage

Bidon 0,6 l (jusqu’à 250 g)

D'autres volumes d'emballage sont disponibles sur demande du client

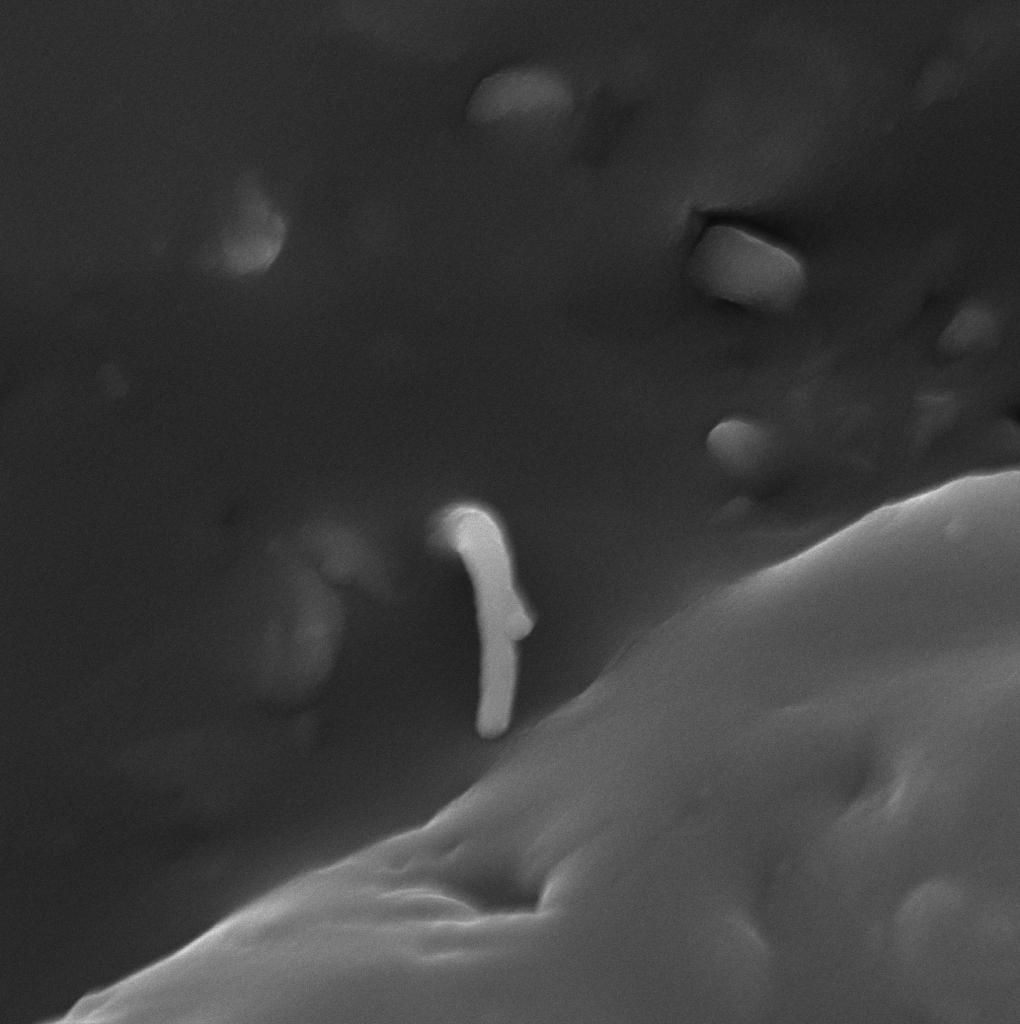

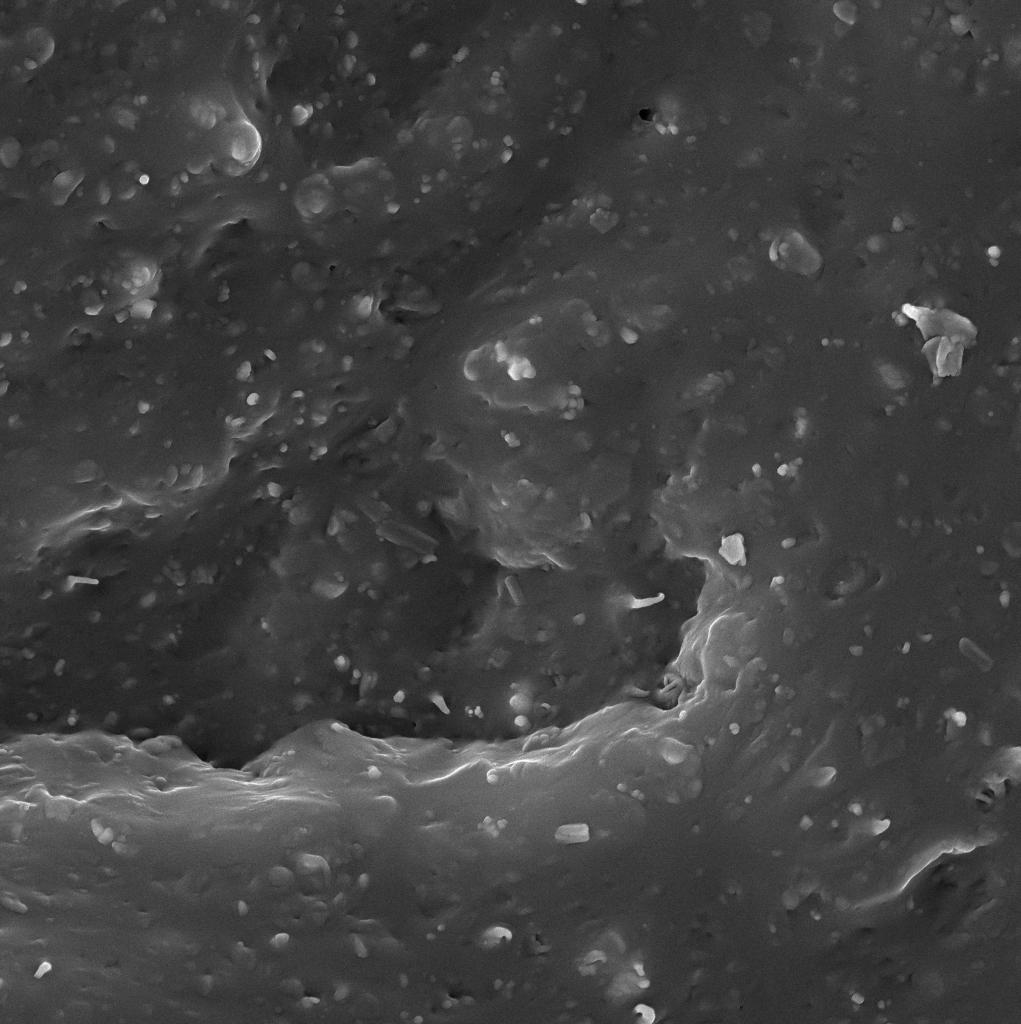

TUBALL™ MATRIX 610 is a versatile masterbatch specifically designed for EPDM rubber compounds.

TUBALL™ nanotubes provide a permanent, stable level of electrical conductivity and improve the mechanical properties of various types of EPDM.

The cost of our SWCNT products depends on the quantity ordered. Please reach out to us for a personalized quote.

Classe de matériaux

Rubber

Dosage de travail

3–6 wt.%

Composants de base:

Polymer, paraffinic mineral oil

Forme

Pâte

Utilisation

Electrical conductivity

Provides uniform, permanent electrical conductivity

Mechanical properties

- Improves a range of mechanical properties such as tensile modulus and tear strength by up to 70%

- Makes it possible to maintain a low hardness of compounds without losses in elastic behavior

Easy to use

- Allows use of standard processing and mixing equipment

- Carrier compatible with a wide range of EPDM grades, formulations and fillers

Retains сolor

- Allows coloration

- Non-marking compounds

Applications industrielles

Accessoires en epdm pour les câbles

cliquez pour voir les cas

Tapis roulants et rouleaux en skept

cliquez pour voir les cas

Vidéo

How to obtain conductive rubbers with graphene nanotubes - Processing guide

Marking and non-marking conductive rubbers: How to avoid mistakes

Vidéo

Caoutchoucs EPDM antistatiques colorés - Recommandation d'utilisation (eng)

Élastomères de nanotubes conducteurs d’électricité: comment éviter la dégradation mécanique et de la couleur (eng)

Documents

Disponible en langues :

English

TUBALL MATRIX 610 PROCESSING KEY POINTS ENG V01.PDF

PDF102.4 kB

TUBALL MATRIX 610 PROCESSING GUIDELINES ENG V03.PDF

PDF716.8 kB

TDS TUBALL MATRIX 610 ENG V06.PDF

PDF409.6 kB