Additivo conduttivo per il poliuretano aromatico ed alifatico esente da solventi (poliestere, polietere, TDI/MDI, ecc.) e per i sistemi fenolici. Ampiamente applicato nei rivestimenti in PU e negli elastomeri solidi. Impatto minimo sulla resina originale, grazie a un dosaggio di lavoro più basso rispetto a TUBALL™ MATRIX 209

Vantaggi

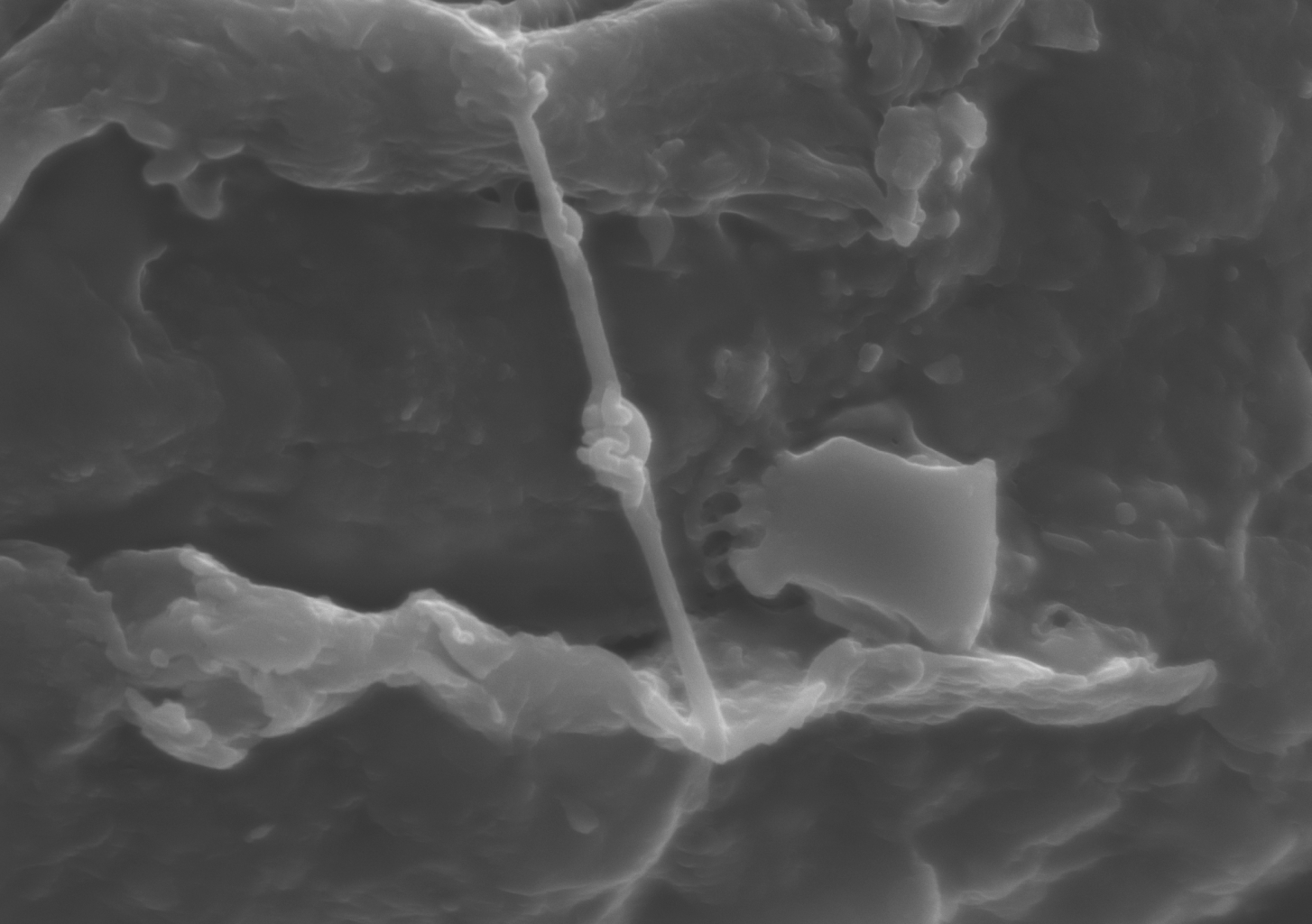

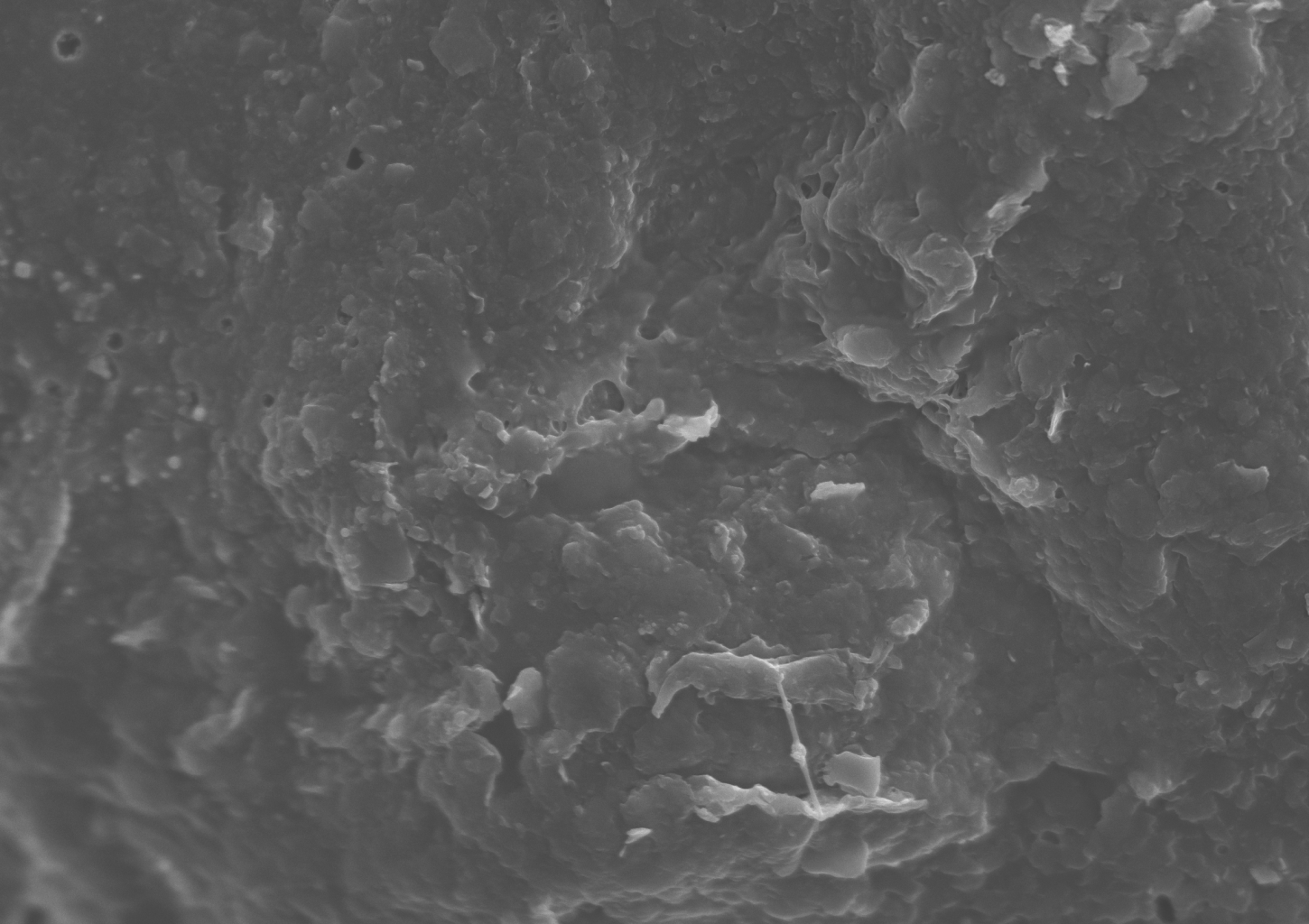

Assicura la conducibilitá elettrica in modo uniforme e permanente senza "hot spots"

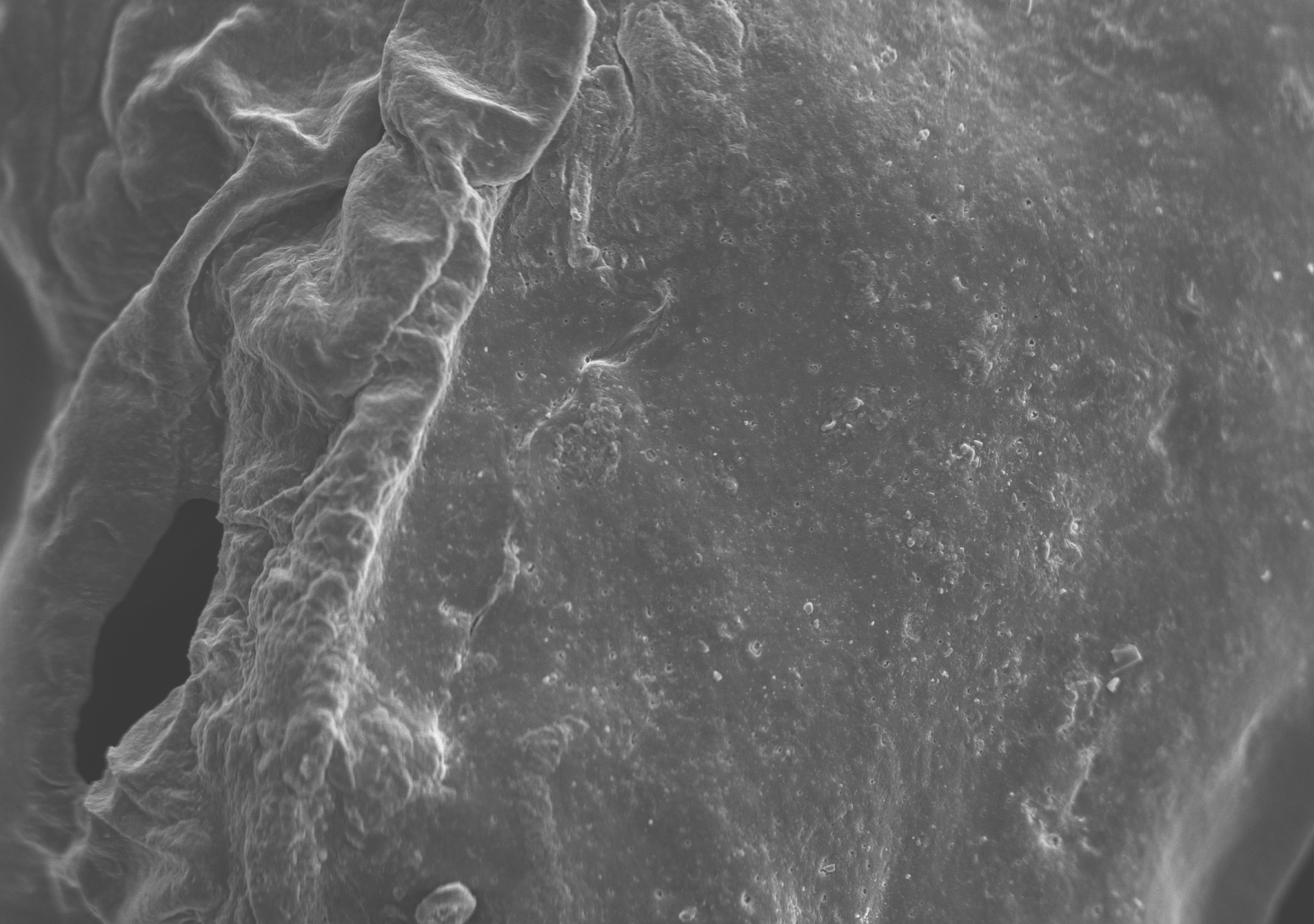

Mantiene o (addirittura) migliora le proprietà meccaniche

La colorazione della resina epossidica è possibile grazie al basso dosaggio richiesto del concentrato e al suo minimo effetto grigio

La formula predispersa consente l'utilizzo delle attrezzature di produzione standard

Incide in misura minima sulla densità, sulla viscosità e sulle altre proprietà reologiche della matrice

Applicazioni principali

Esempi di applicazioni

Alberi per uso industriale

Filtri in poliuretano

La stampa digitale offset

Video

TUBALL™ MATRIX – Guida all'applicazione (en)

Anti-static polyurethane casting and coatings - Processing guide for TUBALL™ MATRIX 202/209