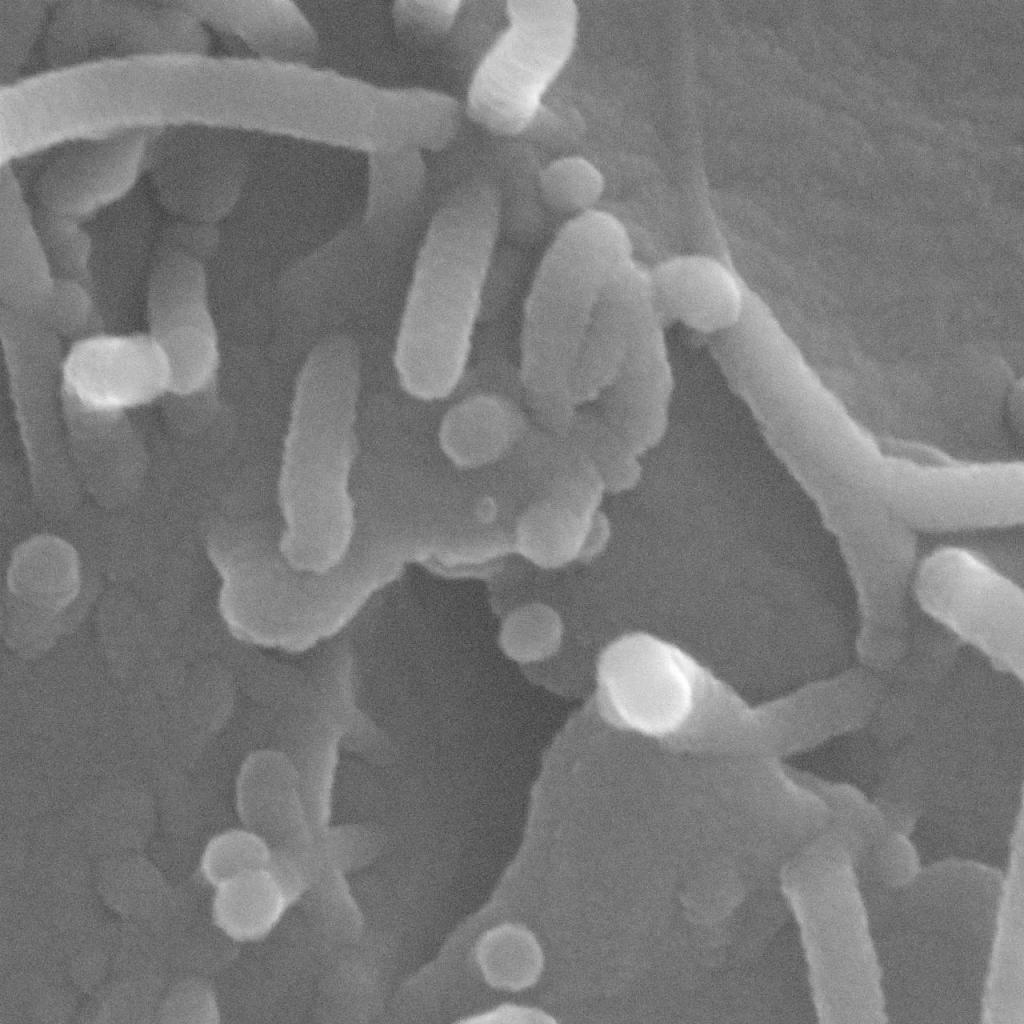

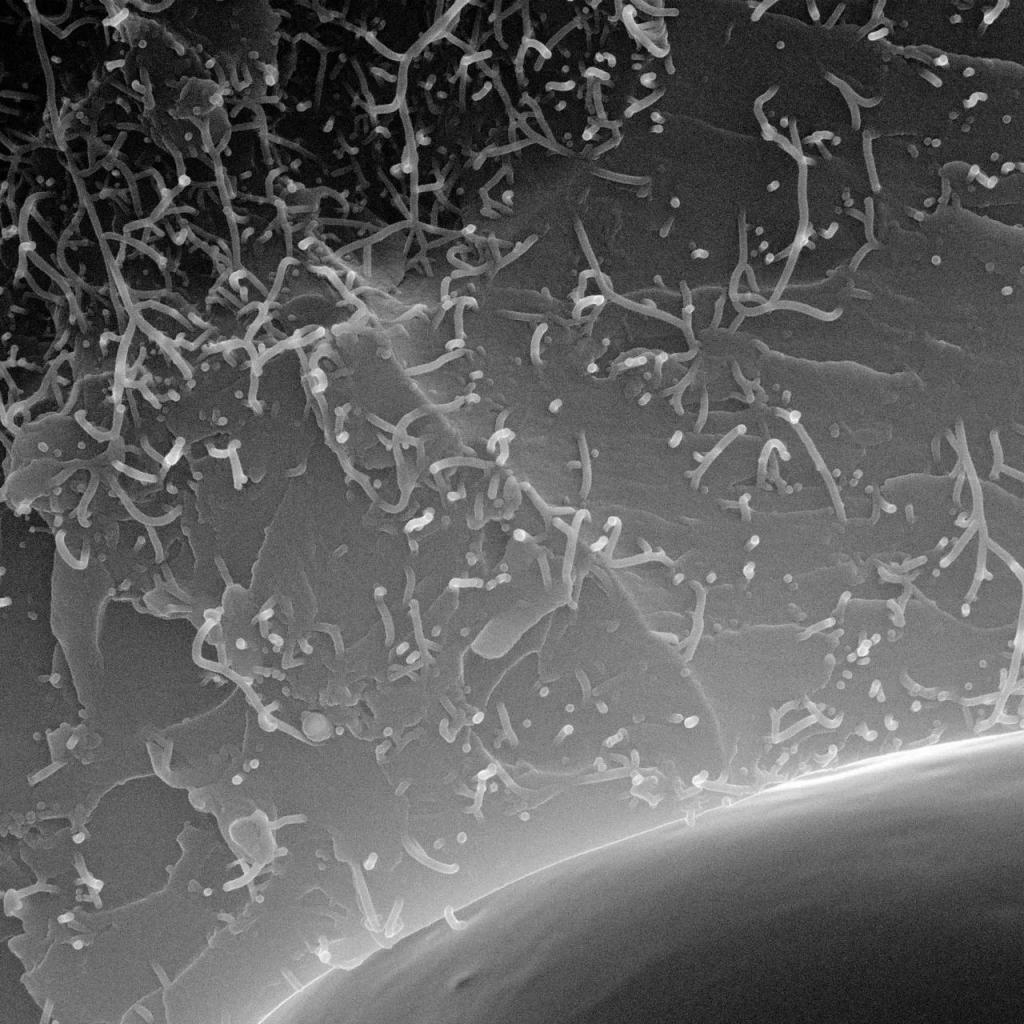

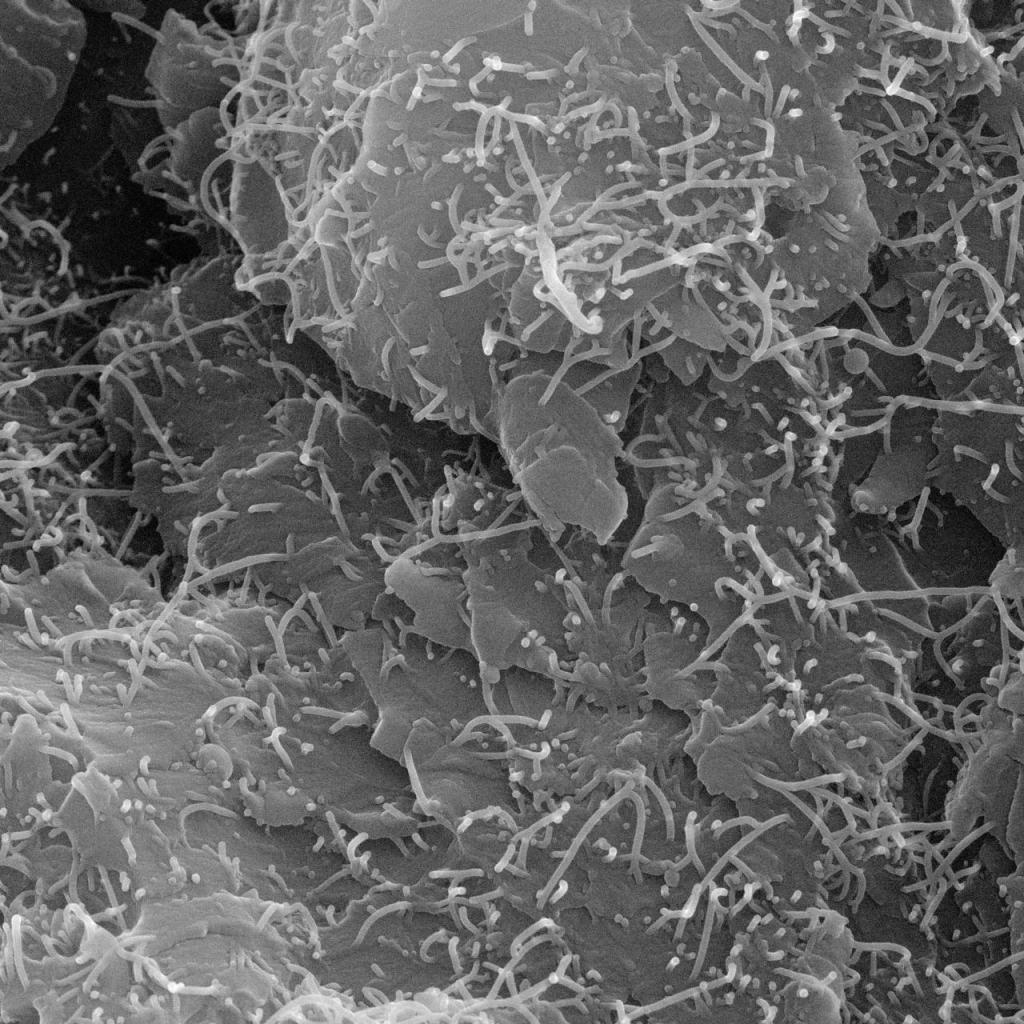

Additivo conduttivo a base di tensioattivo per i rivestimenti epossidici e in PU esenti da solventi, senza difetti nel colore e nelle proprietà meccaniche. È anche consigliato per i compositi epossidici.

Vantaggi

Assicura la conducibilitá elettrica in modo uniforme e permanente senza "hot spots"

Proprietà antistatiche indipendenti dall'umidità

Mantiene o (addirittura) migliora le proprietà meccaniche

La colorazione della resina epossidica è possibile grazie al basso dosaggio richiesto del concentrato e al suo minimo effetto grigio

Incide in misura minima sulla densità, sulla viscosità e sulle altre proprietà reologiche della matrice

La formula predispersa consente l'utilizzo delle attrezzature di produzione standard

Esempi di applicazioni

Cartucce di stampa

Pavimentazione epossidica

Profili in vetroresina per cavi

Video

TUBALL™ MATRIX – Guida all'applicazione (en)

Anti-static and conductive hand layup composites: how to produce using graphene nanotubes