In Epoxy

가소제 (Glycidyl ether group) 기반의 전도성 첨가제 (무용제 에폭시 시스템): 색상이나 기계적인 물성에 미치는 영향이 적음

소재 종류

무용매 에폭시 수지

사용량

0.1~1 wt.%

농축 캐리어

가소제 – 지방산 글리시딜에스터

형태

Paste

주요 특징

Full resistivity range

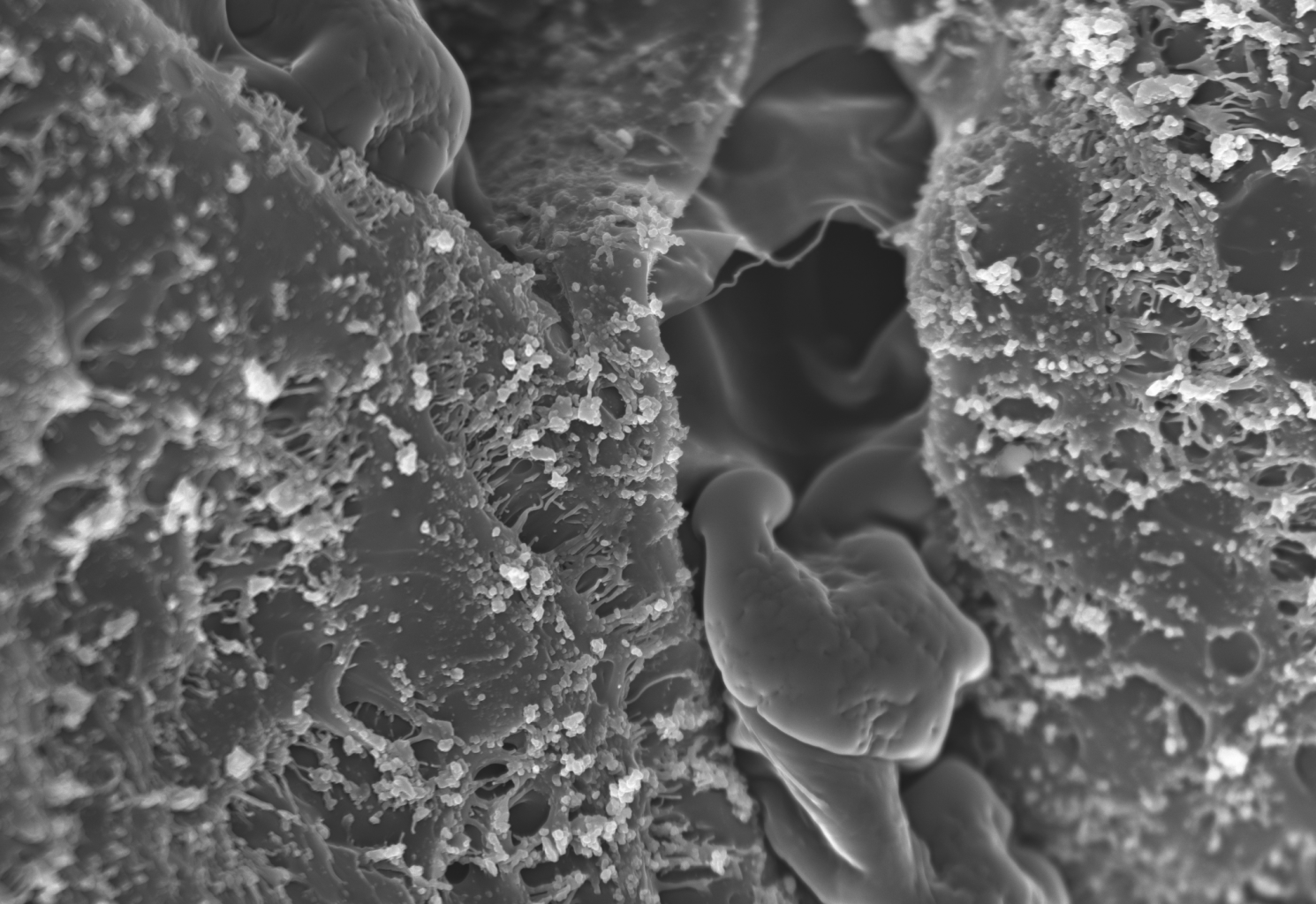

Ensures permanent, uniform conductivity and anti-static properties without “hot spots”

Mechanical performance

Maintains or even increases mechanical performance

Retained color

Allows retention of bright and light colors of materials

Easy to use

The concentrate form greatly simplifies the handling of nanotubes without additional changes to standard manufacturing processes

Viscosity retained

Minimizes the impact on viscosity and density of the host material

적용사례

탱크 라이닝 코팅

click to view case

프린팅 롤러

click to view case

대전방지 에폭시 바닥재

click to view case

비디오

TUBALL MATRIX — Processing Guidelines

자료 다운로드

Also available in:

English

TDS TUBALL MATRIX 201 ENG V09.PDF

PDF204.8 kB

TUBALL MATRIX 200X 300X PROCESSING KEY POINTS ENG V03.PDF

PDF8 MB

TUBALL MATRIX 200X 300X PROCESSING GUIDELINES ENG V04.PDF

PDF512 kB