Nachrichten

22. Januar 2026

Today in Merl, Luxembourg, the OCSiAl team and those close to him are saying farewell to Alexander Khasin.

Alexander, you are with us. We will do everything we can to ensure that your work and scientific contributions live on.

Lesen Sie weiter auf LinkedInAlexander, you are with us. We will do everything we can to ensure that your work and scientific contributions live on.

21. Januar 2026

[#MeetUs] 🚀 Interested in advanced composites?

Join us at MECOC EXPO–the 5th Middle East Metallurgy, Corrosion & Coatings Expo – and discover how graphene nanotube solutions can enhance safety and sustainability in the energy industry.

Upgrade your products with TUBALL™ nanotubes. At ultra-low loadings of just 0.01–0.05%, they deliver:

• ⚡ Electrical conductivity of 10⁴–10⁹ Ω·cm

• ✅ Compliance with key industrial standards

• 🔧 Easy processing with mainstream production technologies

• 🌿 Clean manufacturing with no carbon dust

Let’s connect and explore what’s next for advanced composites and coatings!

#ConductiveComposites #ConductiveCoatings #Composites

Lesen Sie weiter auf LinkedInJoin us at MECOC EXPO–the 5th Middle East Metallurgy, Corrosion & Coatings Expo – and discover how graphene nanotube solutions can enhance safety and sustainability in the energy industry.

Upgrade your products with TUBALL™ nanotubes. At ultra-low loadings of just 0.01–0.05%, they deliver:

• ⚡ Electrical conductivity of 10⁴–10⁹ Ω·cm

• ✅ Compliance with key industrial standards

• 🔧 Easy processing with mainstream production technologies

• 🌿 Clean manufacturing with no carbon dust

Let’s connect and explore what’s next for advanced composites and coatings!

#ConductiveComposites #ConductiveCoatings #Composites

21. Januar 2026

20. Januar 2026

What makes our graphene nanotube technology truly unique?

🔹 Quality. High-performance material with batch-to-batch consistency

🔹 Scalability. Industrial-scale production with unlimited capacity

🔹 Affordability. Lower production costs that make this advanced material more accessible

Together, these advantages turn OCSiAl graphene nanotubes into a practical solution for real-world applications.

#Technology #SWCNT #CNT

Lesen Sie weiter auf LinkedIn🔹 Quality. High-performance material with batch-to-batch consistency

🔹 Scalability. Industrial-scale production with unlimited capacity

🔹 Affordability. Lower production costs that make this advanced material more accessible

Together, these advantages turn OCSiAl graphene nanotubes into a practical solution for real-world applications.

#Technology #SWCNT #CNT

15. Januar 2026

[#MeetUs] It’s time to meet again in 2026!

Let’s connect to share insights on graphene nanotubes and their benefits across multiple industries.

📅 Don’t miss out! Schedule a meeting with us. See you soon! 👋

MECOC EXPO PaintIndia Silicone Expo Tire Technology Expo InterBattery

Lesen Sie weiter auf LinkedInLet’s connect to share insights on graphene nanotubes and their benefits across multiple industries.

📅 Don’t miss out! Schedule a meeting with us. See you soon! 👋

MECOC EXPO PaintIndia Silicone Expo Tire Technology Expo InterBattery

14. Januar 2026

This year we proudly celebrated the 10th anniversary of the OCSiAl China office–a decade of vision, dedication, and remarkable achievements. By now, TUBALL™ has become a key enabler of the most advanced applications across Asia, driven by the fast launch and expansion of local licensed production, along with proactive distributors and a rapidly growing customer base.

But our deepest gratitude goes to the Asian team for your unwavering commitment, tireless efforts, and passionate belief in the power of nanotubes. Your energy and dedication have been instrumental in shaping this success.

Here’s to celebrating this incredible milestone – and to reaching even greater heights together in the next many-many years! 🚀✨

#Team #Anniversary

Lesen Sie weiter auf LinkedInBut our deepest gratitude goes to the Asian team for your unwavering commitment, tireless efforts, and passionate belief in the power of nanotubes. Your energy and dedication have been instrumental in shaping this success.

Here’s to celebrating this incredible milestone – and to reaching even greater heights together in the next many-many years! 🚀✨

#Team #Anniversary

13. Januar 2026

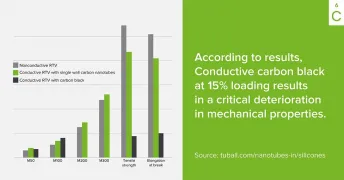

Replace 15% Carbon Black with just 0.3% Graphene Nanotubes to advance your silicone ⚡️

Graphene nanotubes secure:

· ESD and Conductivity ⚡️

· Good mechanical properties 💪

· Maintained rheology 🧪

· Wide color palette 🎨

· Standard processing 🏭

Lesen Sie weiter auf LinkedInGraphene nanotubes secure:

· ESD and Conductivity ⚡️

· Good mechanical properties 💪

· Maintained rheology 🧪

· Wide color palette 🎨

· Standard processing 🏭

6. Januar 2026

[💡R&D] TUBALL™-Enabled 3D-Printed Bipolar Plates for Direct Ethanol Fuel Cells ⚡️

Lightweight bipolar plates produced by 3D printing 🖨️ bring design flexibility and rapid prototyping to ethanol fuel cells for automotive use. TUBALL™ single wall carbon nanotubes 🧬 create a highly efficient conductive network in polymer matrices, achieving the required conductivity at just 1 wt.% loading ✅. The approach enables tough, low-cost bipolar plates that operate reliably, supporting scalable, biofuel-based fuel cell systems 🌱.

📜 Read the article: https://lnkd.in/dRRpVDjK

Lesen Sie weiter auf LinkedInLightweight bipolar plates produced by 3D printing 🖨️ bring design flexibility and rapid prototyping to ethanol fuel cells for automotive use. TUBALL™ single wall carbon nanotubes 🧬 create a highly efficient conductive network in polymer matrices, achieving the required conductivity at just 1 wt.% loading ✅. The approach enables tough, low-cost bipolar plates that operate reliably, supporting scalable, biofuel-based fuel cell systems 🌱.

📜 Read the article: https://lnkd.in/dRRpVDjK

31. Dezember 2025

✨ As the year comes to a close, we want to say a heartfelt thank you to everyone who has been part of our nanotechnological journey. Together, we’ve shared new achievements, exciting breakthroughs, and bold hopes—all united by one dream: to make the world a better place for all living beings. 🌍🧬

May the new year ahead be bright, successful, and full of new possibilities. 🎆✨ We look forward to continuing this journey with all of you in 2026! 🚀💫

Lesen Sie weiter auf LinkedInMay the new year ahead be bright, successful, and full of new possibilities. 🎆✨ We look forward to continuing this journey with all of you in 2026! 🚀💫

30. Dezember 2025

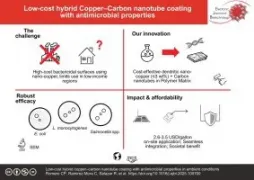

[💡R&D] Bactericidal nanotech surfaces are increasingly adopted in high-tech sectors due to their proven effectiveness. By using TUBALL™ SWCNTs to reinforce conductivity and mechanical stability, this hybrid Cu–CNT coating delivers antimicrobial action with ≤3 wt.% nano-copper 🧪and can be applied under ambient conditions like a standard varnish.

📉 Result: E. coli below compliance levels in under 30 minutes, with low-cost scalability for everyday surfaces.

👉 Read the full article here: https://lnkd.in/dnu4zc49

Lesen Sie weiter auf LinkedIn📉 Result: E. coli below compliance levels in under 30 minutes, with low-cost scalability for everyday surfaces.

👉 Read the full article here: https://lnkd.in/dnu4zc49

23. Dezember 2025

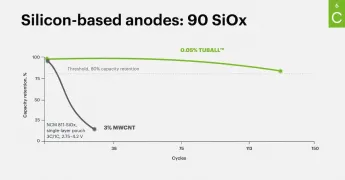

⚠️The biggest barrier to high-silicon anodes is the loss of cycle life as silicon content increases.

📈 As silicon loading rises to unlock higher energy density, particle expansion and conductive network failure accelerate degradation.

🔗 Manufacturers using TUBALL™ SWCNTs break through this long-standing barrier, enabling higher silicon loadings without sacrificing durability.

🔹 Rethink what limits your anode design.

#Siliconanodes #batteries #SWCNT #conductivity

Lesen Sie weiter auf LinkedIn📈 As silicon loading rises to unlock higher energy density, particle expansion and conductive network failure accelerate degradation.

🔗 Manufacturers using TUBALL™ SWCNTs break through this long-standing barrier, enabling higher silicon loadings without sacrificing durability.

🔹 Rethink what limits your anode design.

#Siliconanodes #batteries #SWCNT #conductivity

22. Dezember 2025

✨ Dear friends, teammates, and partners! On this Christmas Eve, we are sending you our warmest greetings from all around the world. Different voices from our team have come together as one, sharing a single message of warmth, gratitude, and holiday spirit.

We’d love to hear from you too—share your holiday greetings in the comments below. 💬🌍

May this festive season bring you joy, peace, and inspiration. 🎄✨

#Christmas2025 #NY2026

Lesen Sie weiter auf LinkedInWe’d love to hear from you too—share your holiday greetings in the comments below. 💬🌍

May this festive season bring you joy, peace, and inspiration. 🎄✨

#Christmas2025 #NY2026

19. Dezember 2025

[#Hiring] The end of the year is often a time to rethink what comes next. If you’re aiming higher in 2026, OCSiAl offers the opportunity to join a global high-tech leader shaping the future of advanced materials. We’re growing fast—and we’re looking for talented, curious, and like-minded people to join our team.

👉 Check our vacancies and send your CV here: https://lnkd.in/dCyh9VJh

#Team #Vacancies #Career

Lesen Sie weiter auf LinkedIn👉 Check our vacancies and send your CV here: https://lnkd.in/dCyh9VJh

#Team #Vacancies #Career

16. Dezember 2025

OCSiAl has opened a new Lab in Serbia 🧪—accelerating the next generation of high-performance silicones.

With TUBALL™ graphene nanotubes, silicones gain permanent conductivity ⚡ while staying soft, elastic, and fully colored 🎨—unlocking new possibilities for EVs, robotics, and advanced wearables.

A major step toward smarter, safer, more reliable materials. 🚀

Read the news in full: https://lnkd.in/ga_Dmv9M

#EVTech #Robotics #Wearables #MaterialScience

Lesen Sie weiter auf LinkedInWith TUBALL™ graphene nanotubes, silicones gain permanent conductivity ⚡ while staying soft, elastic, and fully colored 🎨—unlocking new possibilities for EVs, robotics, and advanced wearables.

A major step toward smarter, safer, more reliable materials. 🚀

Read the news in full: https://lnkd.in/ga_Dmv9M

#EVTech #Robotics #Wearables #MaterialScience

11. Dezember 2025

A data-driven comparison of single wall carbon nanotubes vs multi- and few-wall nanotubes—from morphology and intrinsic properties to real performance in battery applications—was delivered by 余秉駿 (James Yu), Sales Director of OCSiAl in Greater China. Representing the global leader in single wall carbon nanotubes, he took the stage at the International Conference on Carbon Nanomaterials in China—an event that gathered hundreds of leading experts in the field. Expectations were high, and OCSiAl delivered.

James also highlighted the IP and regulatory constraints that continue to limit multi-wall and few-wall materials worldwide—and demonstrated, with evidence from OCSiAl and global partners, why true single wall nanotubes stand in a class of their own, making it clear where the real high-tech frontier lies.

#SWCNTs #batteries #MWCNTs #FWCNTs

Lesen Sie weiter auf LinkedInJames also highlighted the IP and regulatory constraints that continue to limit multi-wall and few-wall materials worldwide—and demonstrated, with evidence from OCSiAl and global partners, why true single wall nanotubes stand in a class of their own, making it clear where the real high-tech frontier lies.

#SWCNTs #batteries #MWCNTs #FWCNTs

10. Dezember 2025

In which battery types can TUBALL™ be used? 🔋

In ALL of them. Just 0.02% TUBALL™ is enough to connect electrode particles in a way that provides an electrode with flexibility, mechanical, and electrical benefits 🔁 — regardless of chemistry. And TUBALL™ is easily added into existing slurry and coating processes, with no production changes needed 🧩.

#SWCNT #CleanTech #EnergyStorage #NextGenBatteries

Lesen Sie weiter auf LinkedInIn ALL of them. Just 0.02% TUBALL™ is enough to connect electrode particles in a way that provides an electrode with flexibility, mechanical, and electrical benefits 🔁 — regardless of chemistry. And TUBALL™ is easily added into existing slurry and coating processes, with no production changes needed 🧩.

#SWCNT #CleanTech #EnergyStorage #NextGenBatteries

9. Dezember 2025

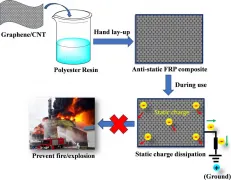

[💡R&D] TUBALL™ enables safer, stronger GFRP for industrial environments, as shown by researchers from Tata Steel Ltd. With the addition of just 0.03 wt.% graphene nanotubes, standard GFRP reaches the 10⁶–10⁷ Ω safety window and gains up to +24% strength and +59% modulus, even after hygrothermal aging.

These lightweight, low-cost composites become suitable for oil & gas, chemical storage, electronics, cable trays, and other spark-sensitive infrastructure.

📜 Read the article: https://lnkd.in/eZ-bVPXh

#Research #GFRPComposites

Lesen Sie weiter auf LinkedInThese lightweight, low-cost composites become suitable for oil & gas, chemical storage, electronics, cable trays, and other spark-sensitive infrastructure.

📜 Read the article: https://lnkd.in/eZ-bVPXh

#Research #GFRPComposites

5. Dezember 2025

As we approach a decade of collaboration with one of OCSiAl’s earliest European distributors, Reschem Italia SpA, our teams have met once again to review progress and set new goals for the coming year and for the long-term development of the Italian market.

We exchanged ideas, explored new TUBALL™ opportunities, and visited the Tempio Voltiano and Villa Bernasconi museums, followed by an enjoyable boat trip across the lake. The energy and commitment from both teams highlighted the strong momentum we’ve built and the clear potential ahead.

This memorable day will only strengthen our partnership and inspire new directions for growth and innovation.

Here’s to the next chapter of progress together! 🚀

#TeamMeeting #Distributor #Partnership

Lesen Sie weiter auf LinkedInWe exchanged ideas, explored new TUBALL™ opportunities, and visited the Tempio Voltiano and Villa Bernasconi museums, followed by an enjoyable boat trip across the lake. The energy and commitment from both teams highlighted the strong momentum we’ve built and the clear potential ahead.

This memorable day will only strengthen our partnership and inspire new directions for growth and innovation.

Here’s to the next chapter of progress together! 🚀

#TeamMeeting #Distributor #Partnership