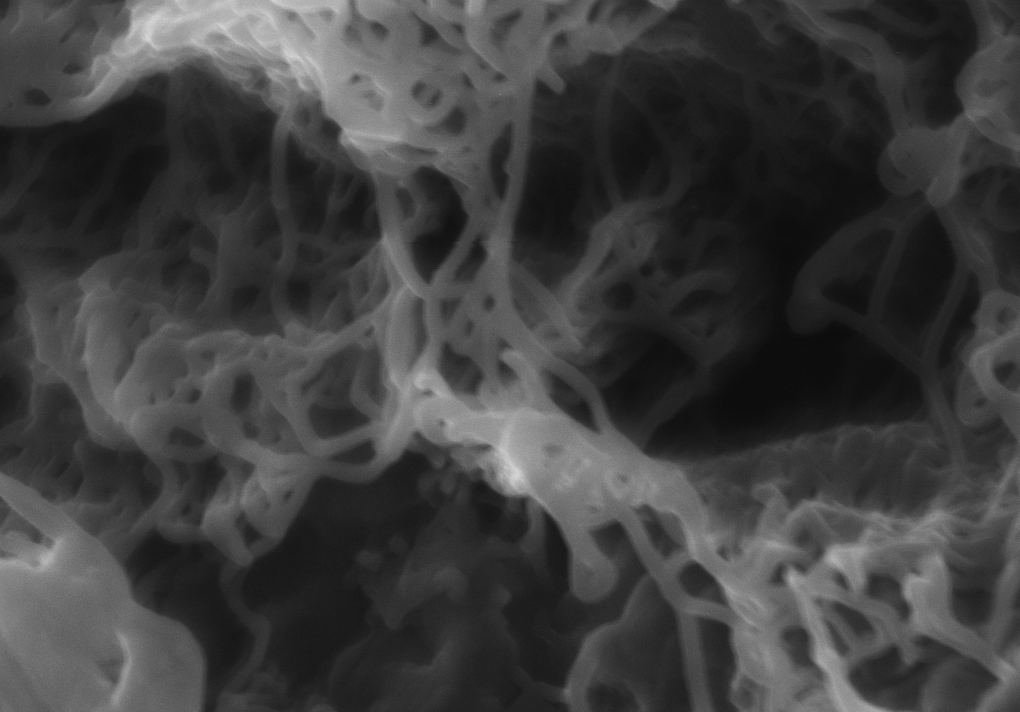

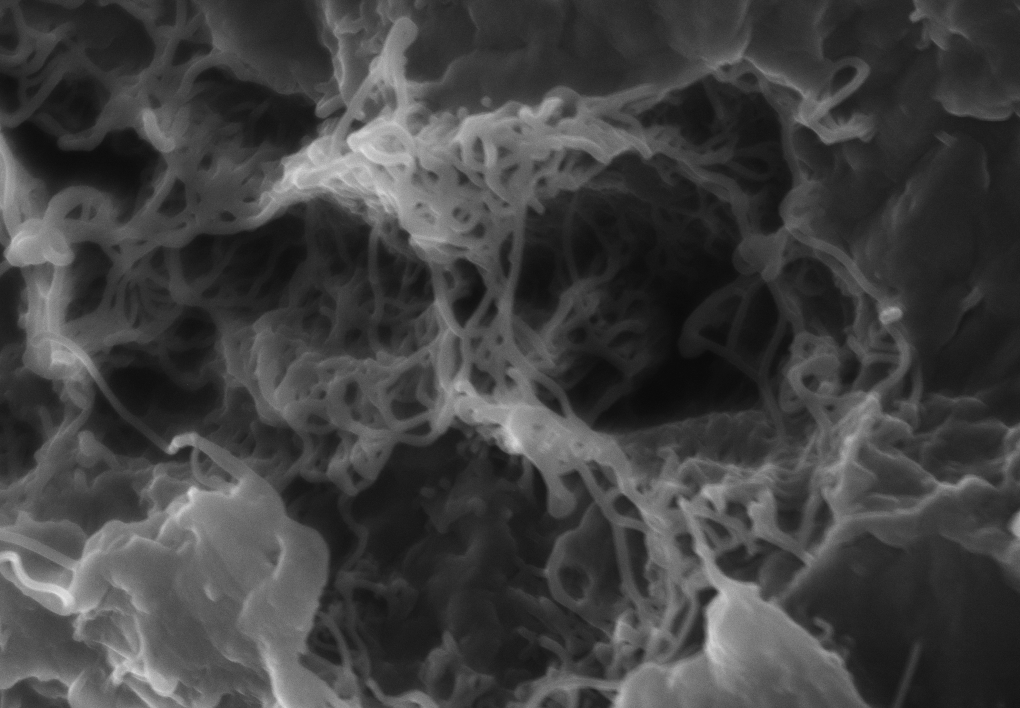

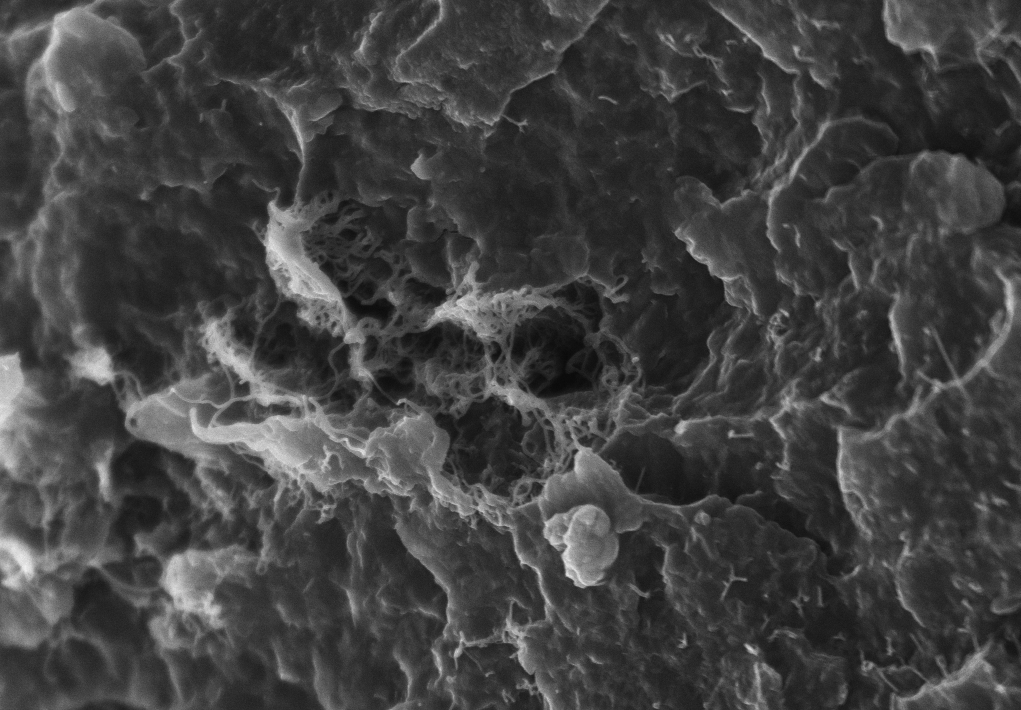

Carbon nanotube products

Embalaje

Tarro 0.6 l (hasta 250 g)

Otros tamaños de embalaje están disponibles a petición del cliente

Aditivo conductor universal para la obtención de compuestos de poliuretano termoplástico (TPU), polisulfuro de fenileno (PPS) rellenado, acrilonitrilo-butadieno-estireno (ABS), policarbonato, ABS-policarbonato, poliamida (PA) y resina de poliamida reforzada con fibra de vidrio.

Materiales del sistema

Poliuretano termoplástico (TPU), polisulfuro de fenileno (PPS) rellenado, acrilonitrilo-butadieno-estireno (ABS), policarbonato, ABS-policarbonato, poliamida (PA) y resina de poliamida reforzada con fibra de vidrio

Dosis operativa

0,5–5% de peso

Matriz

Éster de poliol

Forma

Pellets

Benefits

Conductividad eléctrica

Proporciona una conductividad constante y uniforme a una dosis baja

Propiedades mecánicas

Conserva las características mecánicas iniciales claves

Características constantes

Mantiene la resistividad específica independientemente de los niveles de humedad

Reduce los rechazos

Contribuye a la reducción de los índices de rechazo

Aplicaciones principales

Ejemplos de aplicación

Lámparas de señalización

Pulse para ver todos los casos

Documentos

Disponible en lenguas :

English

TDS TUBALL MATRIX 808 ENG V12.PDF

PDF204.8 kB

TUBALL MATRIX 808 ABS PROCESSING GUIDELINES ENG V04.PDF

PDF204.8 kB

TUBALL MATRIX 808 GF PA6 PA6.6 PROCESSING GUIDE ENG V04.PDF

PDF204.8 kB

Vídeo

How to grant conductivity to glass fiber reinforced polyamide: compounding guide