Graphene nanotubes for thermoset fiberglass composites: conductivity with maintained color and durability

OCSiAl은 공정 적용에 편리하도록 TUBALL™ MATRIX(다양한 폴리머 기반의 TUBALL™ 그래핀 나노튜브 분산제품)를 개발하여 공급하고 있습니다.

"TUBALL™ MATRIX” 제품별로 사용된 폴리머를 확인한 후, 현재 적용 중인 배합과 상용성이 좋은 제품군을 적용하세요:

Target system | Vinyl ester and polyester | |

Additive carrier | Plasticizer + stabilizing agent | Surfactant |

Triethylene glycol dimethacrylate + ammonium salt of polyolefin-based derivatives | Ethoxylated alcohol | |

Product |  |  |

대전방지 및 전도성 열경화성 유리섬유 복합재의 성능 향상

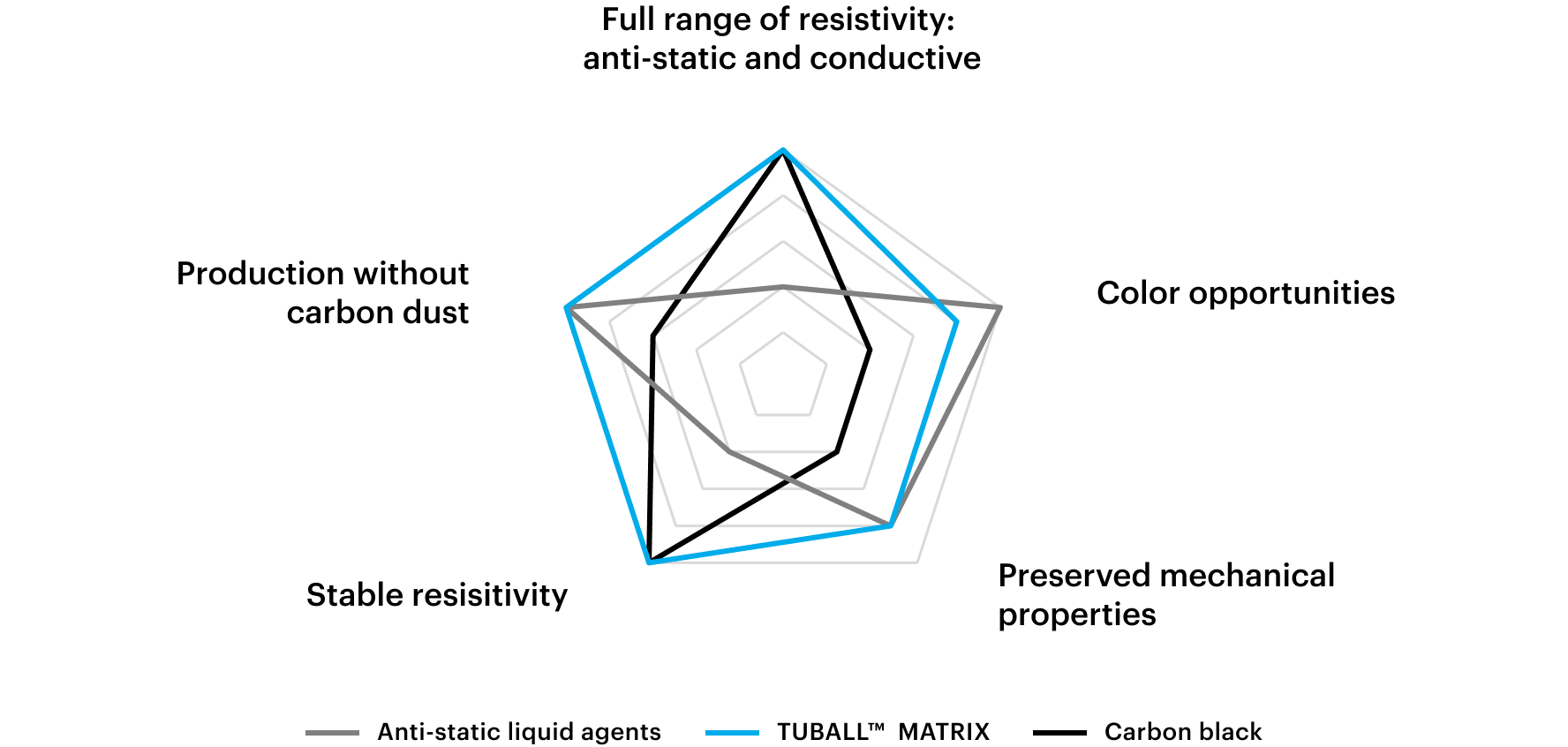

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

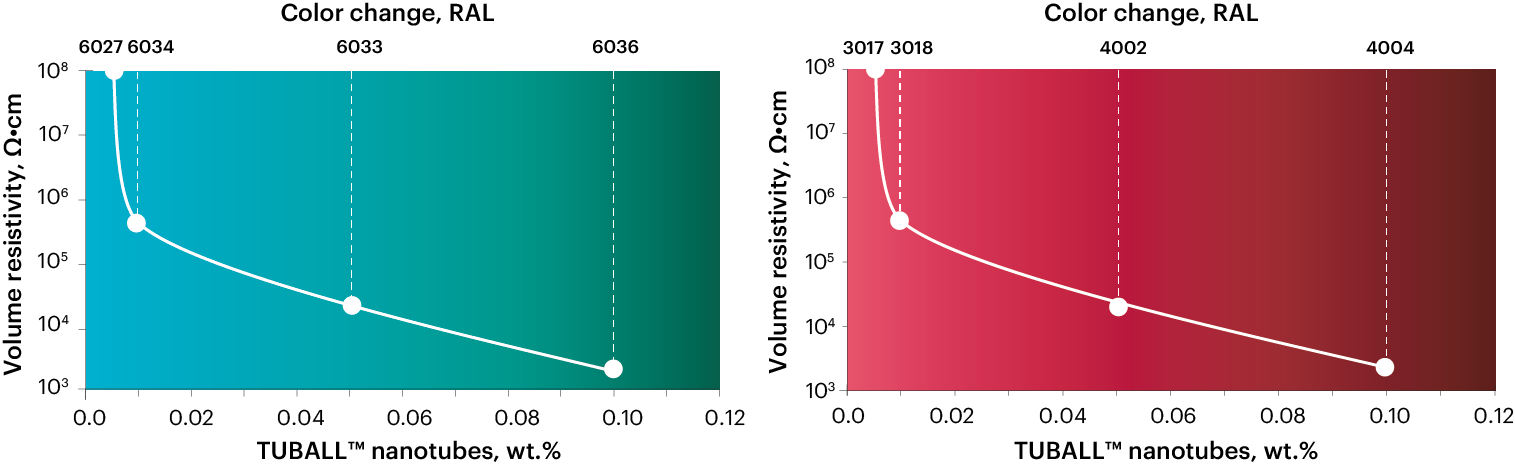

색상에 미치는 영향 없이, 넓은 범위의 전도성 구현 가능

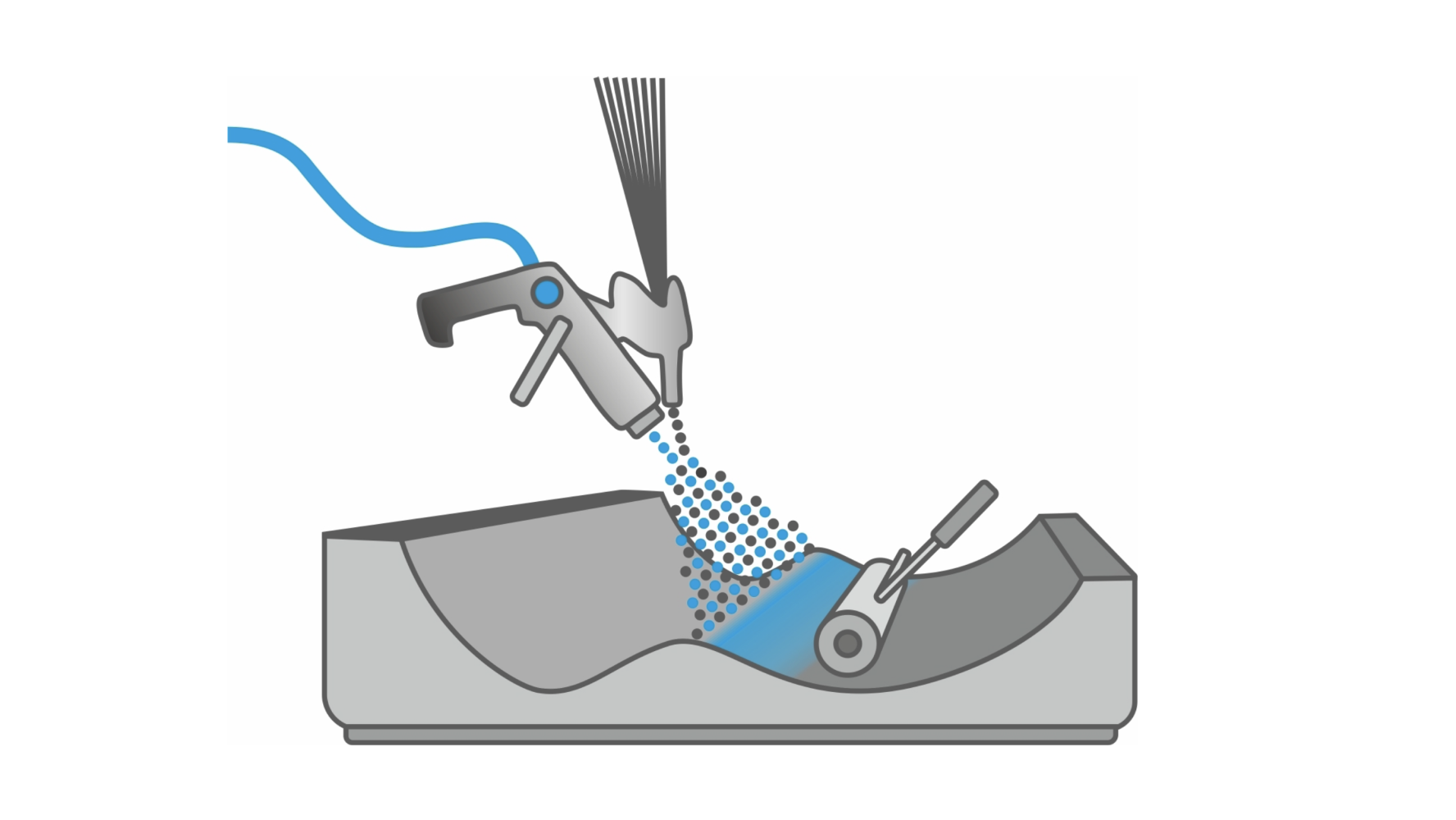

다양한 제조 기술 적용 가능

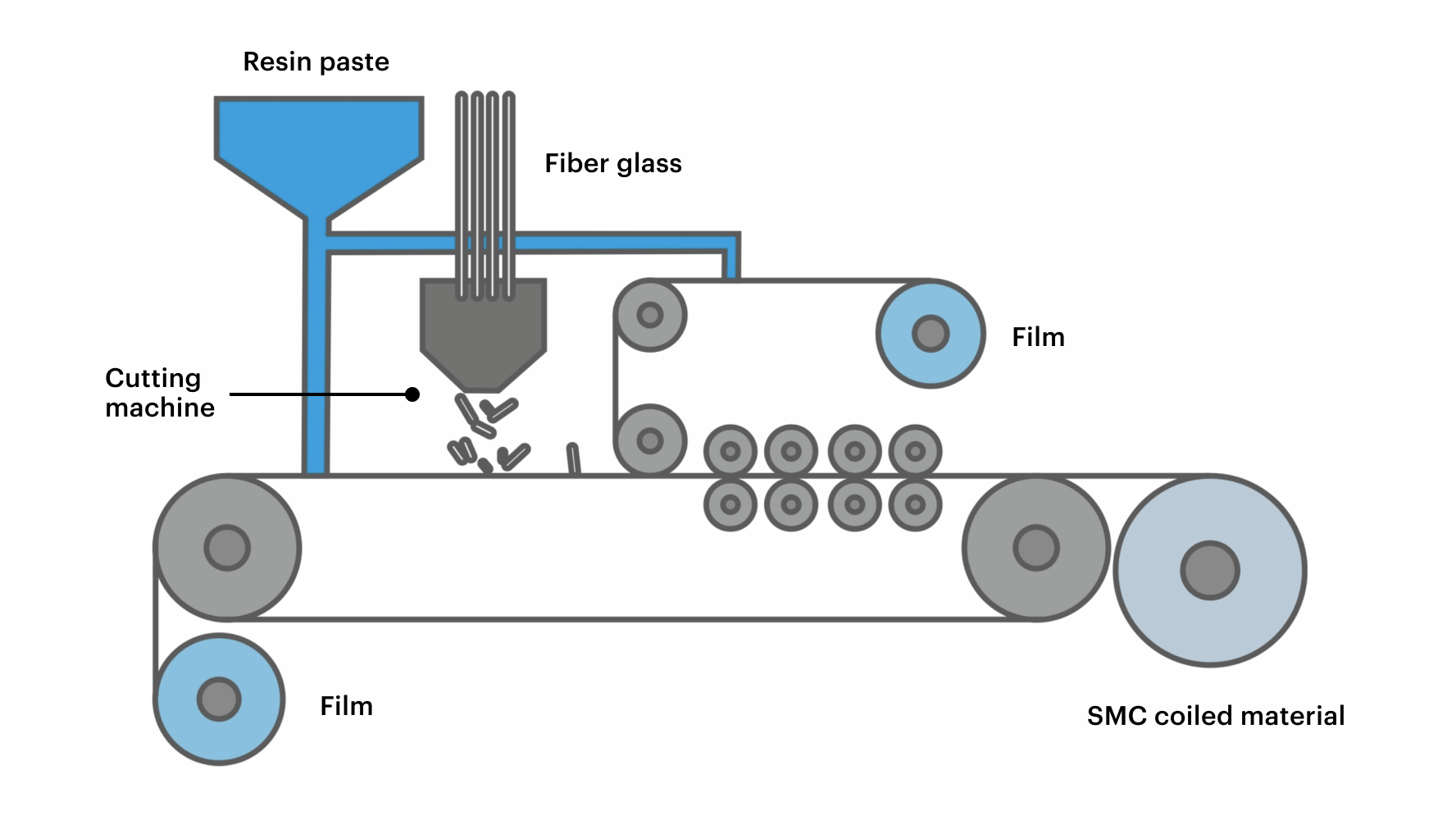

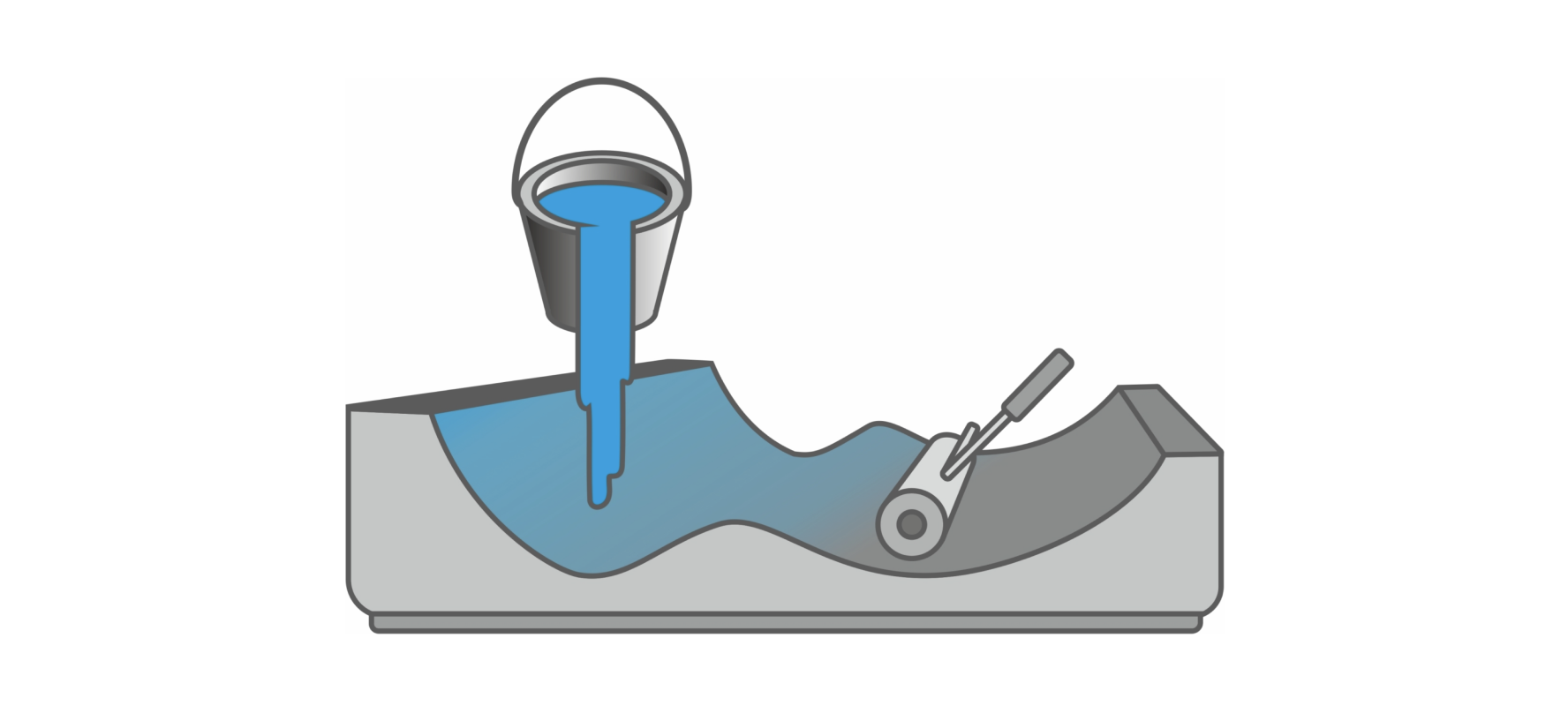

SMC/BMC | Spray-up |

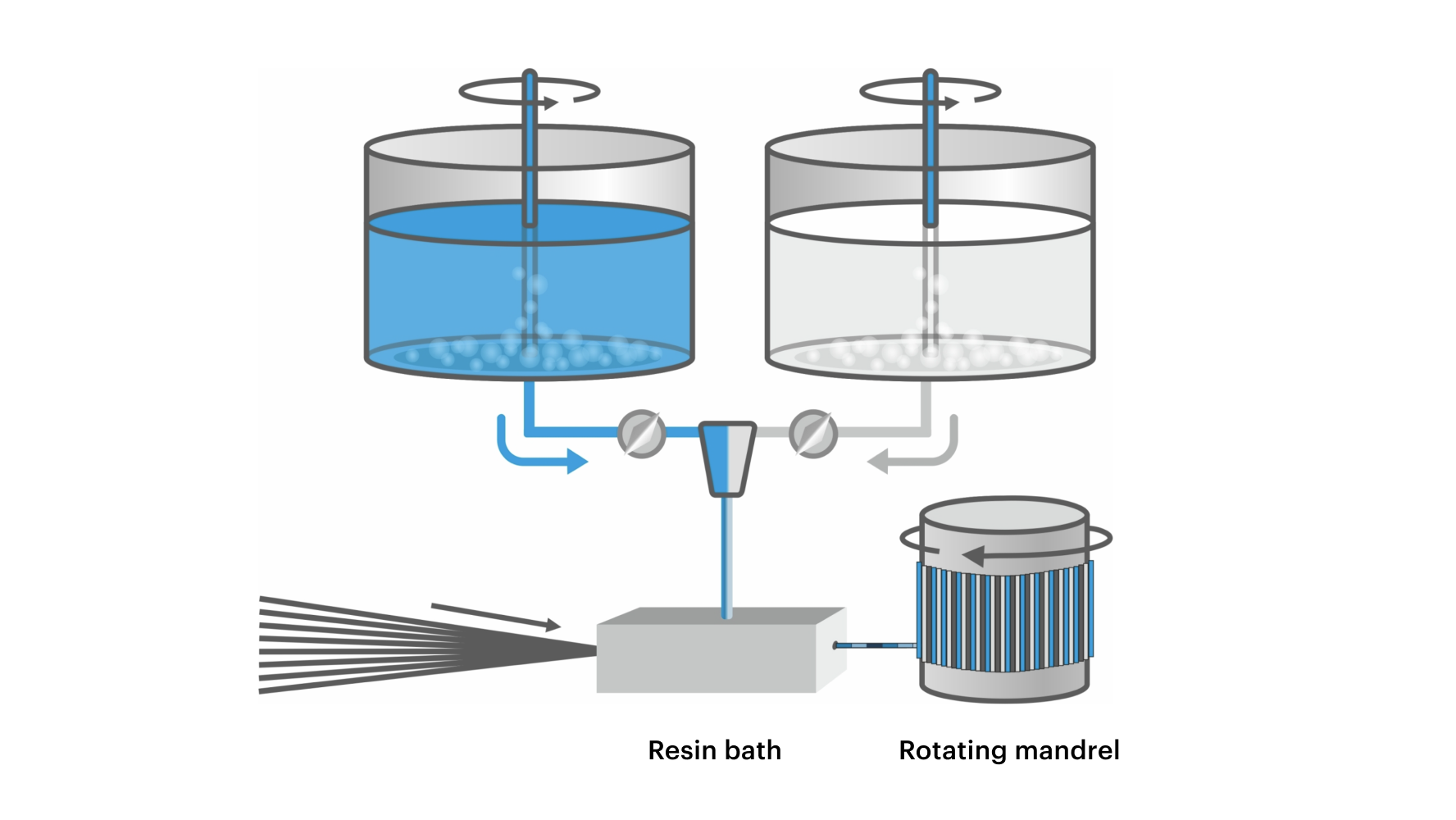

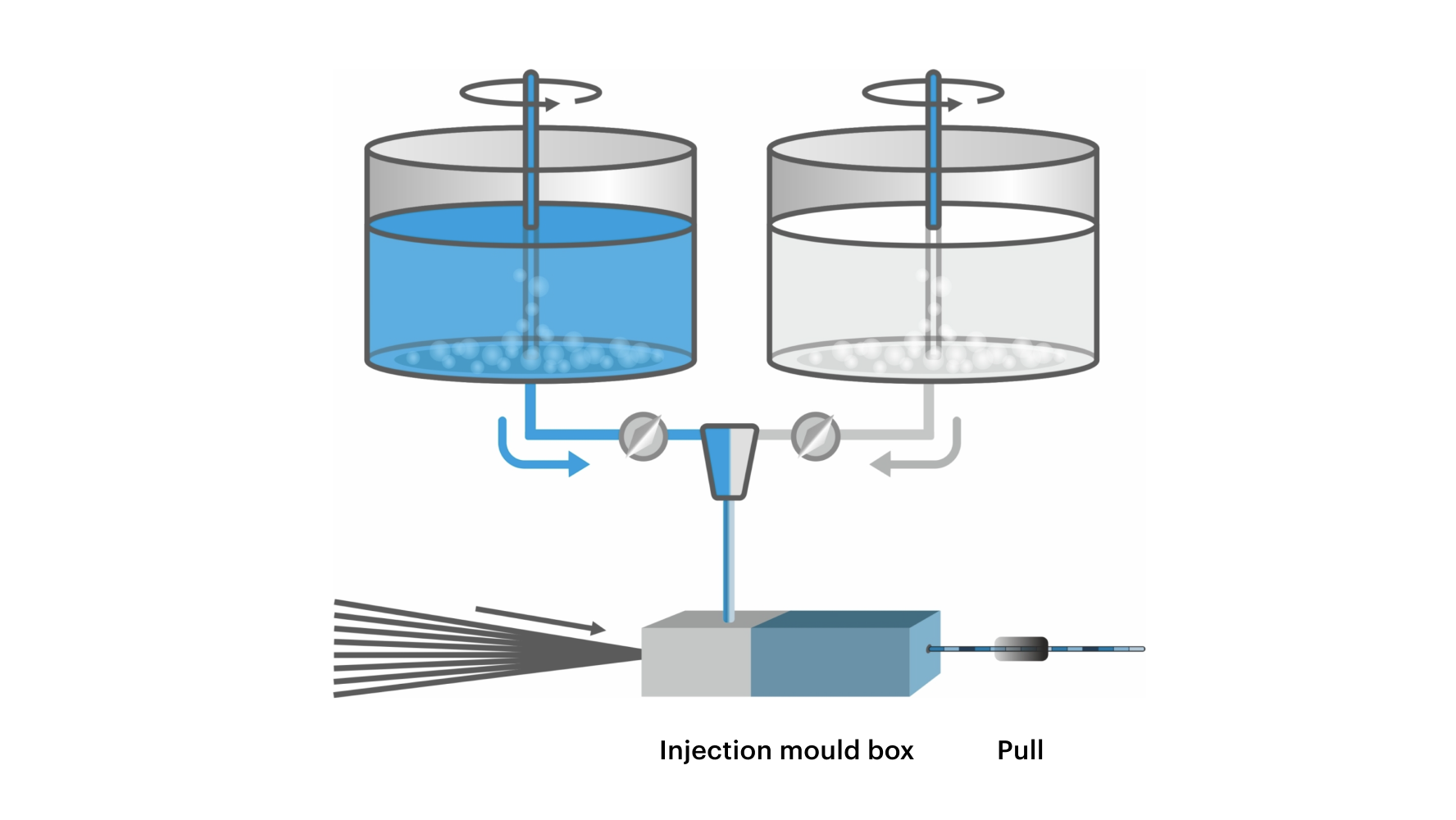

Filament winding | Pultrusion |

Hand layup |

간편한 사용법

TUBALL™ MATRIX anti-static masterbatches can be processed with standard equipment that is widely used in the coatings industry:

Standard single-shaft high-speed mixer

25 min total dilution time

Instant quality control with a grindometer to reach particle size ≤ 15 µm

열경화성 폴리우레탄을 위한 TUBALL™ 그래핀 나노튜브의 기타 특징:

- 제품 적용 시, 점도 변화 최소화

- 사용이 간편하고 소량 사용이 가능해 공정의 복잡성을 줄이고 효율성을 높임

- 핫스팟(과열점) 발생 없이 전도성 유지

For solvent-free and solvent-based polyester and vinyl-ester systems

For solvent-free epoxy systems

Special case

Anti-static filament-winding applications:

Simplified production process

Compared with carbon veil or roving, TUBALL™ nanotubes require lower labor costs and allow conductive pipes and tanks to be produced using the same process as for non-conductive applications. There are thus additional cost savings for producers.

응용 분야

유리섬유 복합재 파이프

유리 섬유 복합재 탱크

SMC 복합제

Pay close attention to the processing guidelines for TUBALL™ MATRIX

PDF 파일 다운로드:

Video instructions for use:

TUBALL™ MATRIX - Processing guidelines

How to increase rotation speed and safety, and reduce the weight of printing cylinders?

추가 정보

Learn more about conductive tooling gelcoat

Conductive gelcoats for safe and efficient fiberglass molds

New generation of conductive UP and EP formulations (Elmar Greiff, BÜFA Composite Systems)

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample.