Graphene nanotubes for conductive tooling gelcoats: efficient and safe demolding

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of anti-static masterbatches based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

For polyester and vinyl-ester resins, TUBALL™ MATRIX 204 should be used.

|

Target system |

|

|

Additive carrier |

Plasticizer + stabilizing agent |

|

Triethylene glycol dimethacrylate + ammonium salt of polyolefins based derivatives |

|

|

Product |

|

Increased efficiency and safety of fiberglass molds with conductive tooling gelcoats

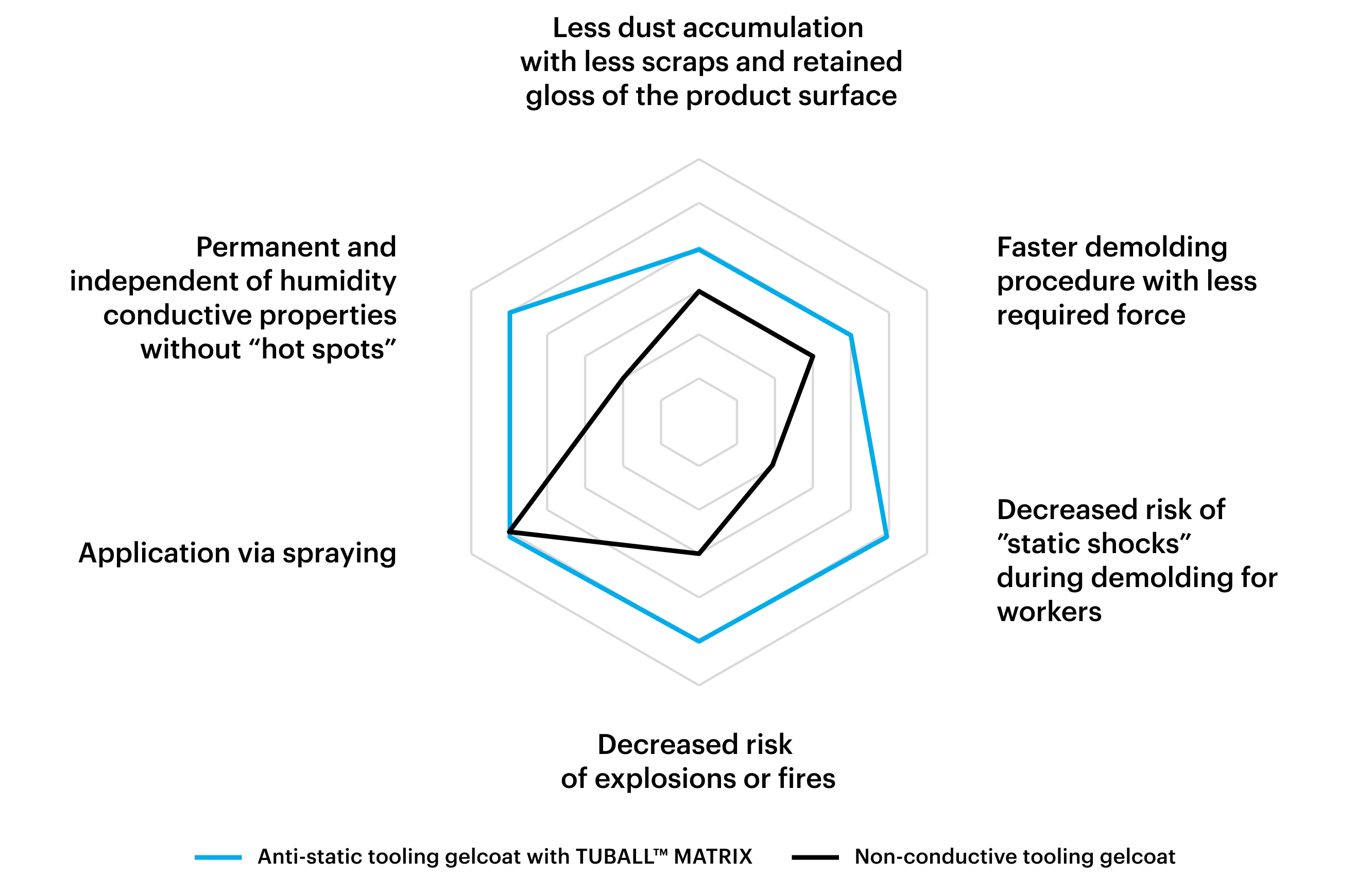

Fiberglass molds with conductive tooling gelcoats, in contrast to molds with traditional non-conductive tooling gelcoats, improve the efficiency of composite production:

- Improved product surface quality: less dust accumulation with less wastage and retained gloss

- Production cycles are shorter: faster de-molding process with less force required

- Improved work safety: decreased risk of “static shocks” during demolding, decreased risk of explosion and fire

Conductive tooling gelcoats with TUBALL™ MATRIX

TUBALL™ MATRIX 204 adds conductive properties to tooling gelcoats, increasing the efficiency and safety of fiberglass molds.

Other benefits provided by TUBALL™ nanotubes for conductive tooling gelcoats:

- Limited impact on viscosity

- Wide range of colors

- Low dosage gives greater flexibility in the final formulation

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, a line of ESD additives based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

For conductive polyester and vinyl-ester resins, TUBALL™ MATRIX 204 should be used

Application case

Polyester Moldcoat

Please pay attention to processing guidelines for 200-x and 300-x series of TUBALL™ MATRIX

Download PDF version:

Or watch the processing guidelines video:

TUBALL™ MATRIX - Processing guidelines

How to make colored conductive gelcoats: unveiling high-performance industrial technology

Additional information

Conductive gelcoats for safe and efficient fiberglass molds

TUBALL™ graphene nanotubes, also known as single wall carbon nanotubes, add conductive properties to tooling gelcoats, increasing the efficiency and safety of fiberglass molds.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample