Graphene nanotubes for glass fiber filled polyamide compounds: conductivity and maintained mechanical properties

TUBALL™ MATRIX 808형태의 TUBALL™ 그래핀 나노튜브는 폴리올 에스테르 캐리어 기반의 다목적 전도성 첨가제입니다. 열가소성 재료에 우수한 전기 전도성을 제공하는 동시에 기계적 특성을 유지하고 유리 섬유 충전 화합물의 MFI 레벨을 유지하도록 특별히 설계되었습니다.

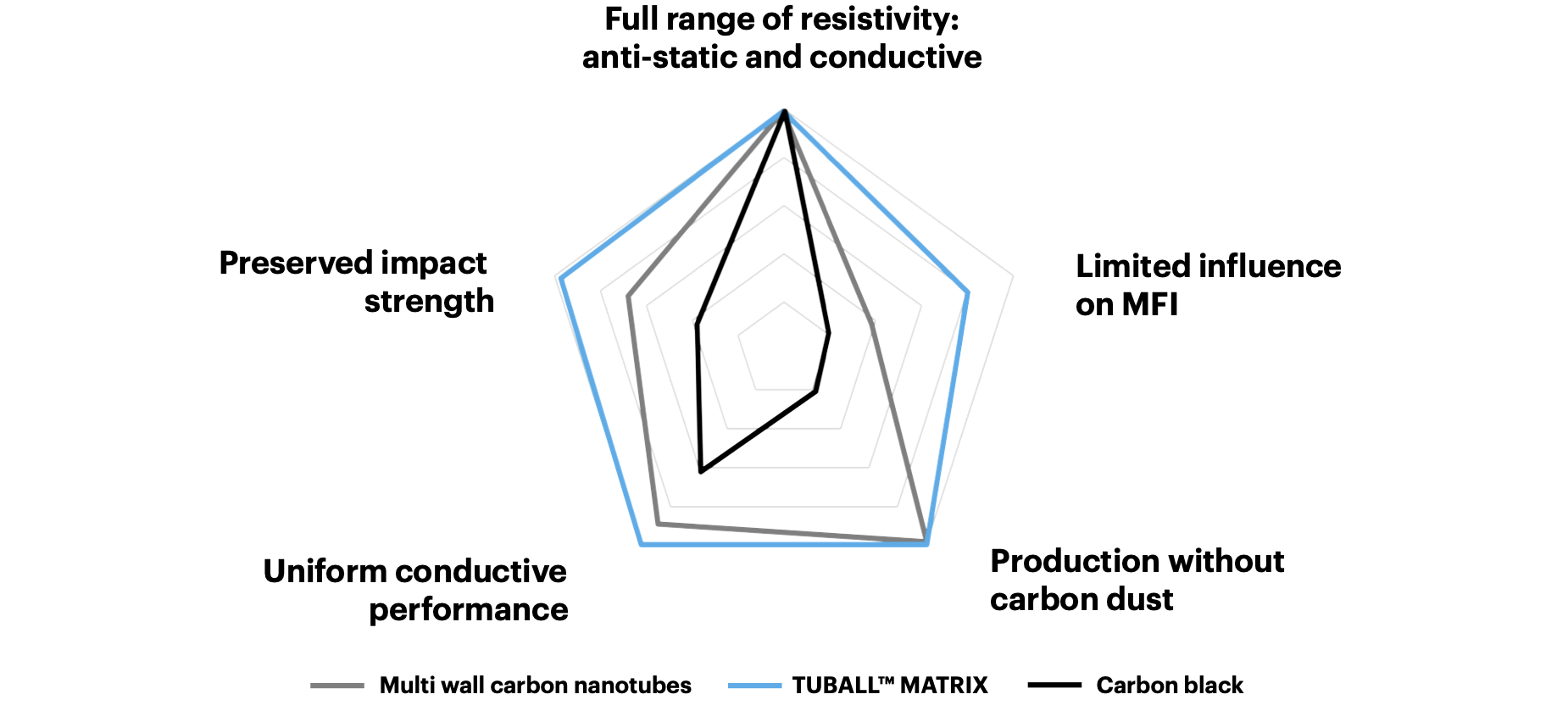

CONDUCTIVE ADDITIVES FOR GLASS FIBER FILLED PA: TRADITIONAL VS TUBALL™

Note. This diagram is based on an average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

고품질의 전도성 폴리아마이드 컴파운드는 자동차 연료탱크, 커넥터, 펌프, 에어 시스템, 석탄 광부를 위한 자급식 자가 구조 장치, 주유기손잡이, 문 손잡이, 다양한 건축 부품 및 ATEX 분야의 ESD 제품 제조 등 정유, 가스, 화학, 전자 산업 등에서 사용됩니다. 또한 나노튜브강화 PA 부품은 자동차 부품의 e-페인팅에도 사용될 수 있습니다.

Benefits provided by TUBALL™ nanotubes for GF-filled PA:

- Ultra-low dosage starting from just 0.05 wt.% TUBALL™ graphene nanotubes*

- Maintains good balance of mechanical properties

- Enables a new combination of GF-filled PA properties in comparison to standard conductive agents

- Permanent, stable and uniform electrical resistivity without “hot spots”

- Stable performance reducing the number of out-of-spec parts

- Good processability and easy handling

- Allows production of conductive parts that retain colors

*Dosages may vary depending on the formulation, processing, and products.

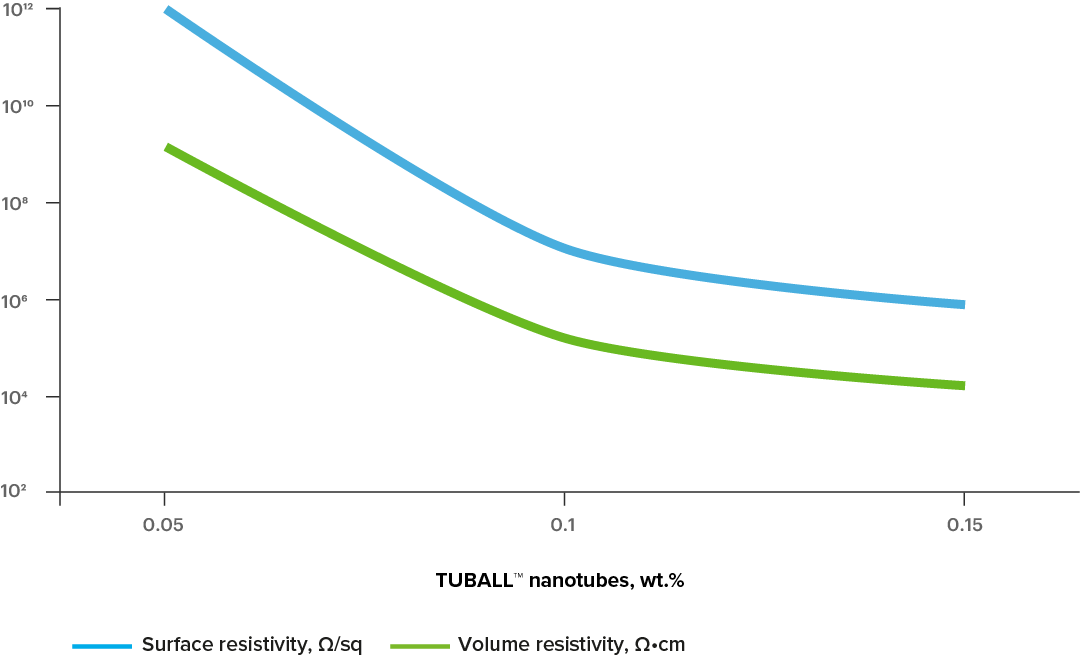

FULL RANGE OF RESISTIVITY

Graphene nanotubes’ unique morphology allows them to create a dense conductive network inside thermoplastic compounds at ultra-low loading rates—starting from just 0.05 wt.% in the total compound.

30% glass fiber filled polyamide compounds. Injection molded samples. Surface resistivity: ASTM D257. Volume resistivity: ASTM D4496.

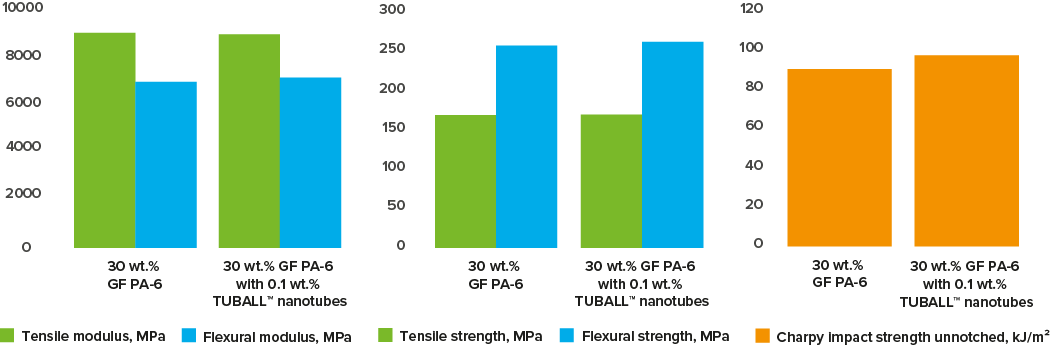

MAINTAINED MECHANICAL PROPERTIES

The usage of TUBALL™ MATRIX preserves key mechanical properties in comparison to other conductive additives.

30% glass fiber filled polyamide-6 compounds. Injection molded samples. Impact strength: ISO 179; Tensile performance: ISO 527; Flexural performance: ISO 178.

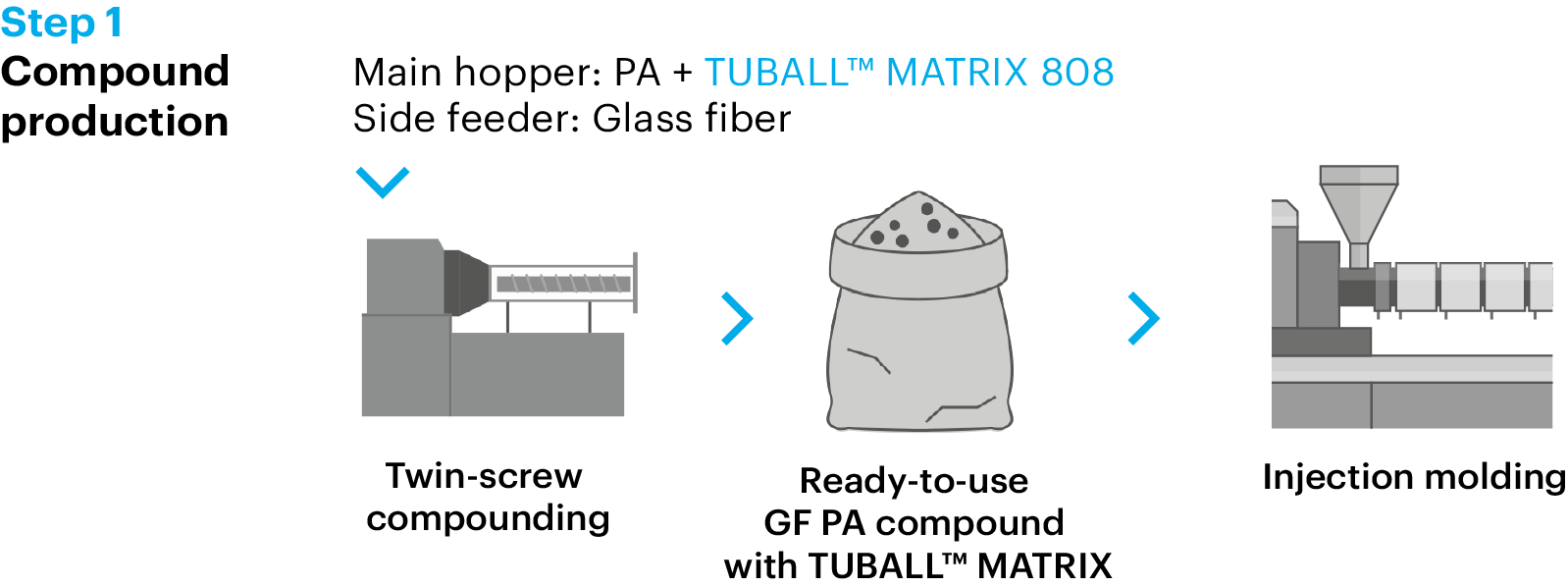

EASY TO APPLY WITH STANDARD EQUIPMENT

TUBALL™ MATRIX can be processed with standard equipment widely used in the thermoplastics industry.

PA enhanced with TUBALL™ graphene nanotubes has found wide usage in the automotive e-painting, automotive safety, ESD materials and ATEX applications.

Pay close attention to the processing guidelines for TUBALL™ MATRIX

Download PDF version:

응용 분야

E-painting

TUBALL™ MATRIX for glass fiber filled polyamide

추가 정보

How to grant conductivity to glass fiber reinforced polyamide: compounding guide

3 methods of quality control for conductive thermoplastics with graphene nanotubes

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample