Graphene nanotubes for polyethylene rotomolding: electrical conductivity with preserved mechanical properties and light colors

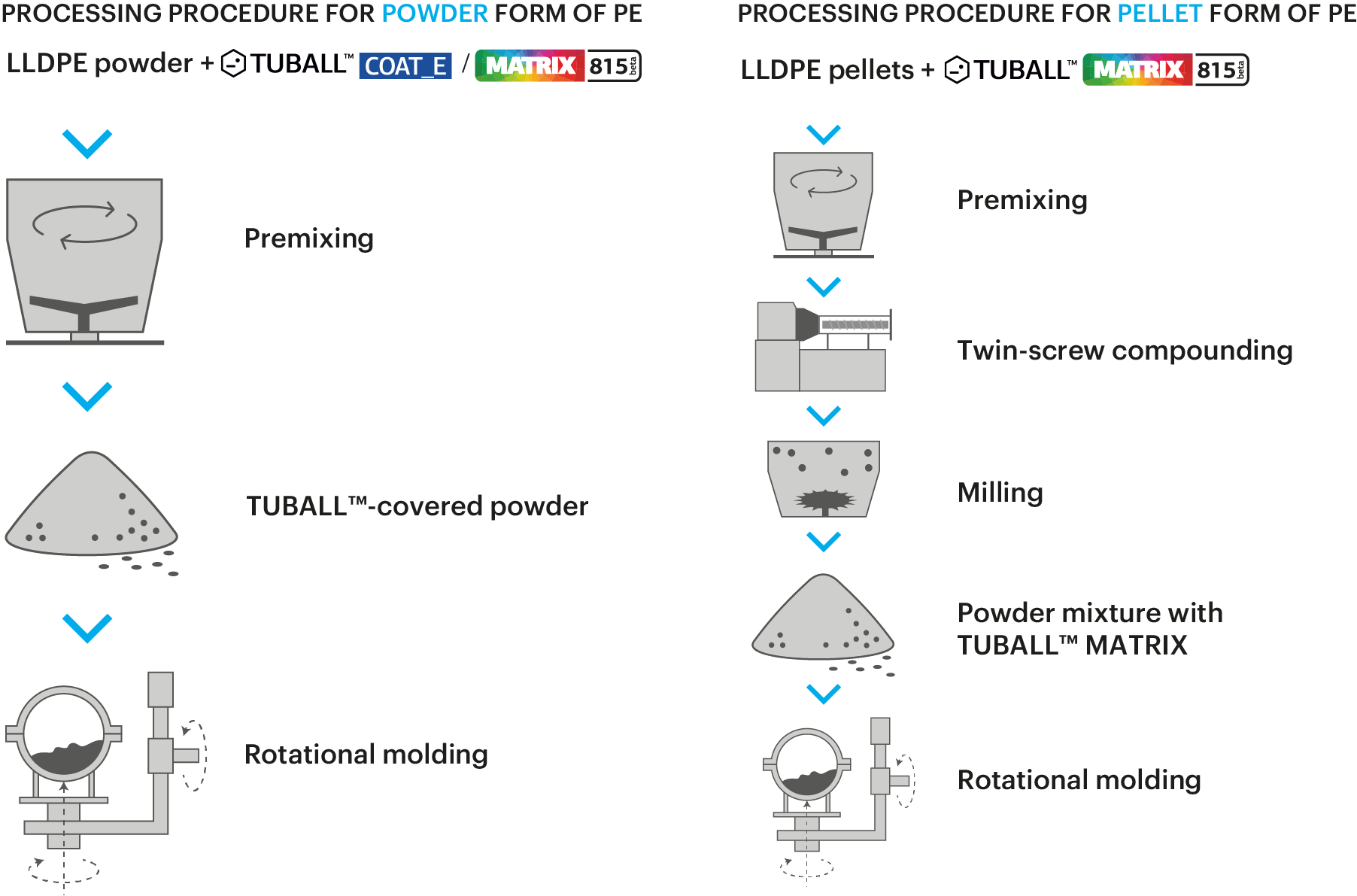

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of additives based on polymer-carriers and pre-dispersed TUBALL™ graphene nanotubes, or TUBALL™ COAT_E suspensions.

Choose the TUBALL™-based product based on your requirements:

*Values may vary depending on the formulation, processing, and products, and are given as a typical reference.

TUBALL™ anti-static additive for polyethylene rotomolded parts demonstrates the following benefits:

- Low dosage starting from 0.01 wt.% TUBALL™ nanotubes to obtain conductive performance*

- Permanent, stable, and uniform electrical resistivity without “hot spots”

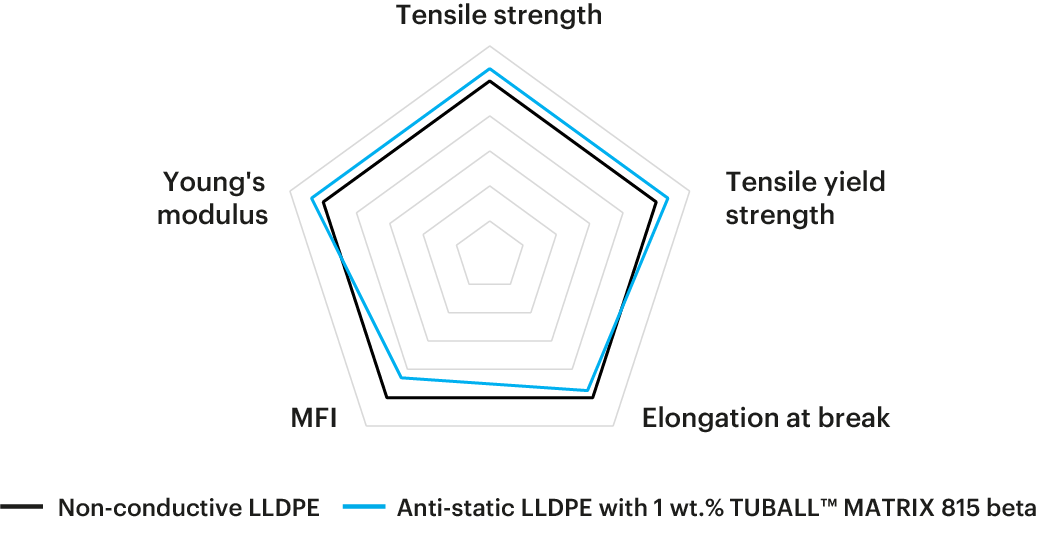

- Maintains a good balance of mechanical properties

- Possibility of color solutions*

- Stable performance reducing the number of out-of-spec parts

*Depending on the formulation, processing, and products.

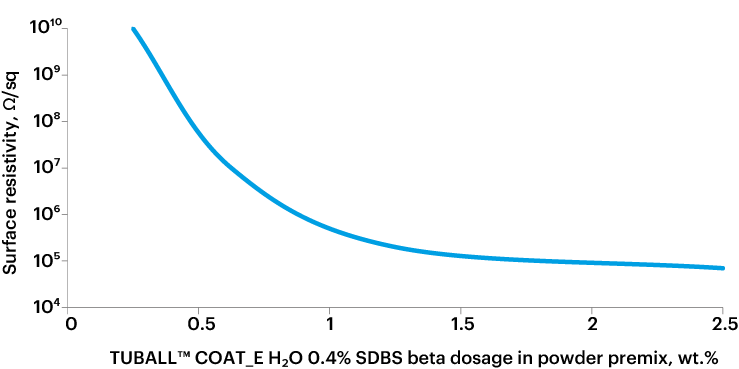

Full range of resistivity: anti-static and conductive

Graphene nanotubes’ unique morphology allows them to create a dense conductive network inside thermoplastic compounds at ultra-low loading rates.

Maintained mechanical properties

OCSiAl internal results.

Conductive polyethylene products manufactured by rotational molding technology have found wide application in flammable/explosive areas, such as in the mining, oil & gas, and other industries.

EASY TO APPLY AT REQUIRED APPROACH

TUBALL™-based products can be processed with standard equipment that is widely used in the thermoplastics industry.

Related products

Application cases

컨테이너(용기)

Pay close attention to the processing guidelines for rotomolding with COAT_E

추가 정보

Anti-static properties in rotomolding: Easy cost-effective solution for the whole conductivity range