Carbon nanotube products

Packaging

Bottle 1 L

Other packaging volumes are available at customers’ request

Cathode

TUBALLBATT NMP

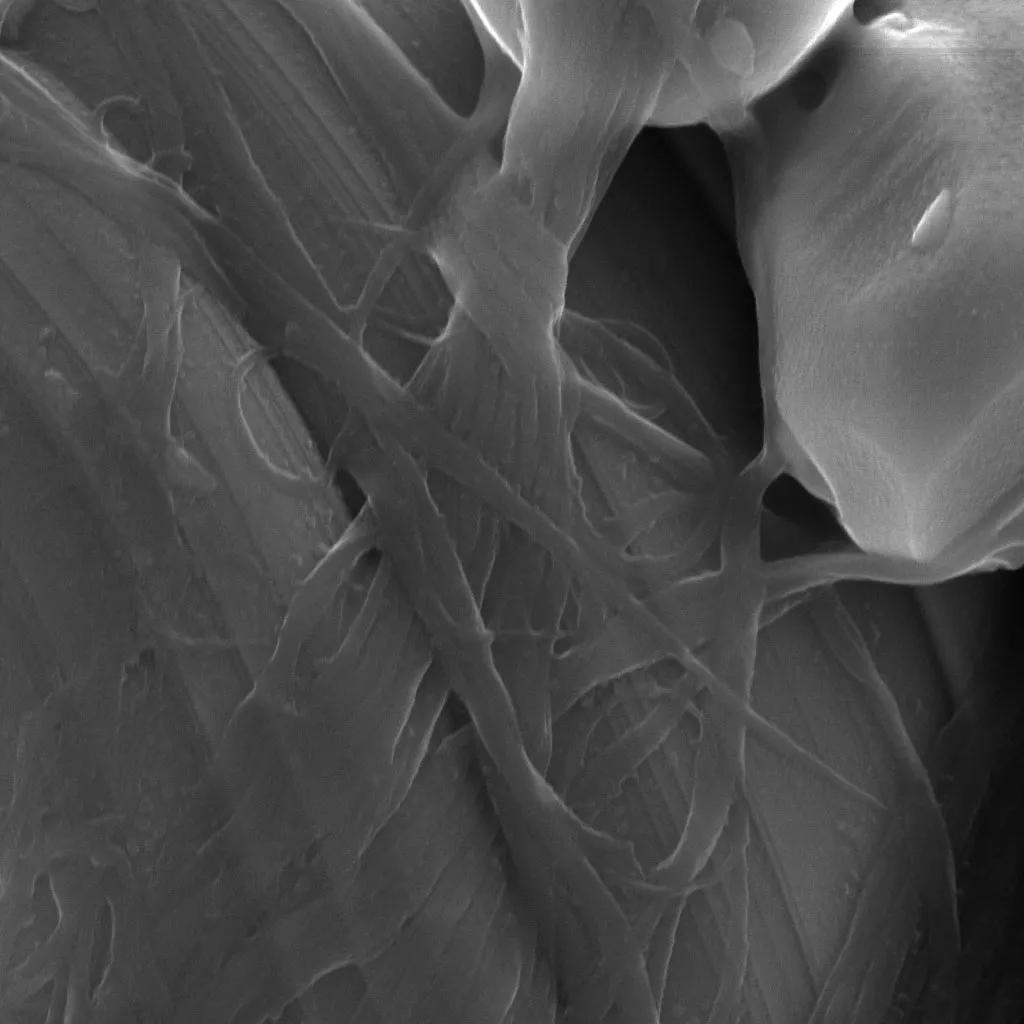

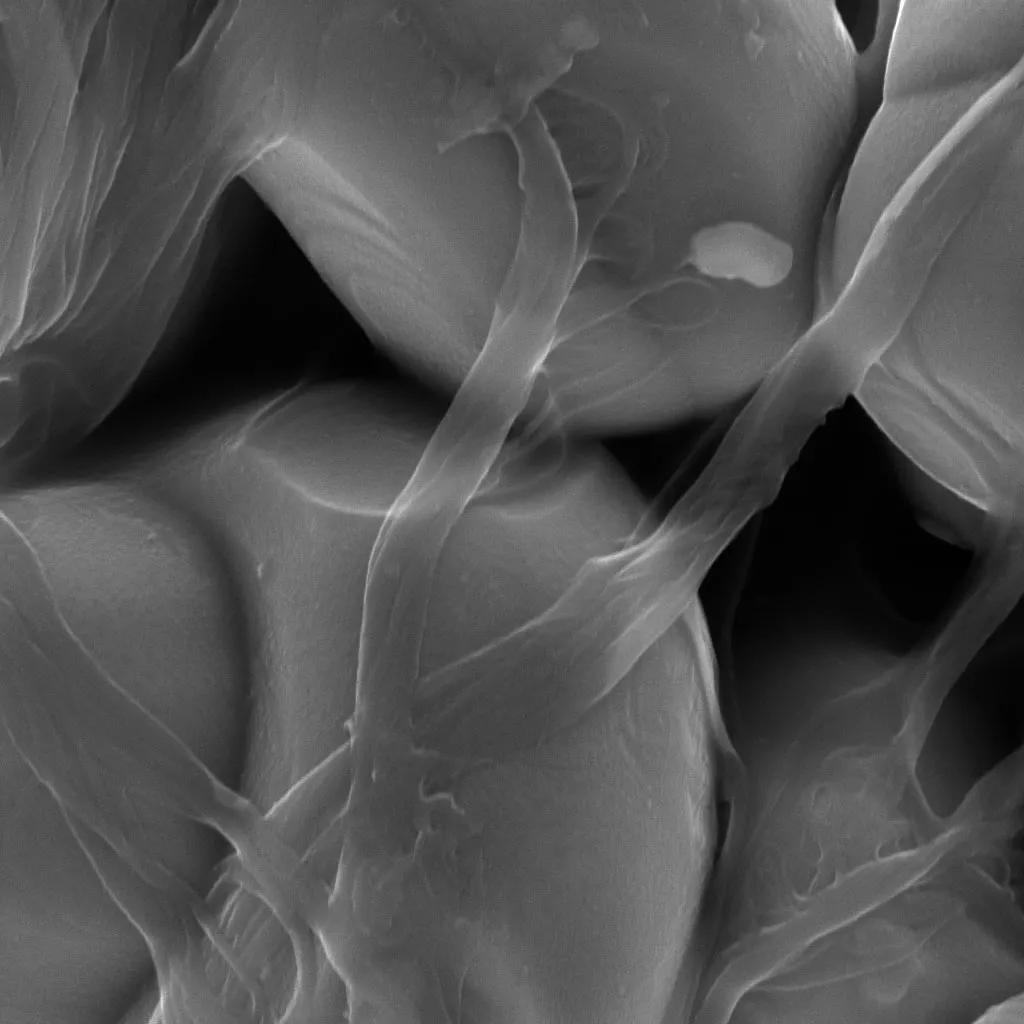

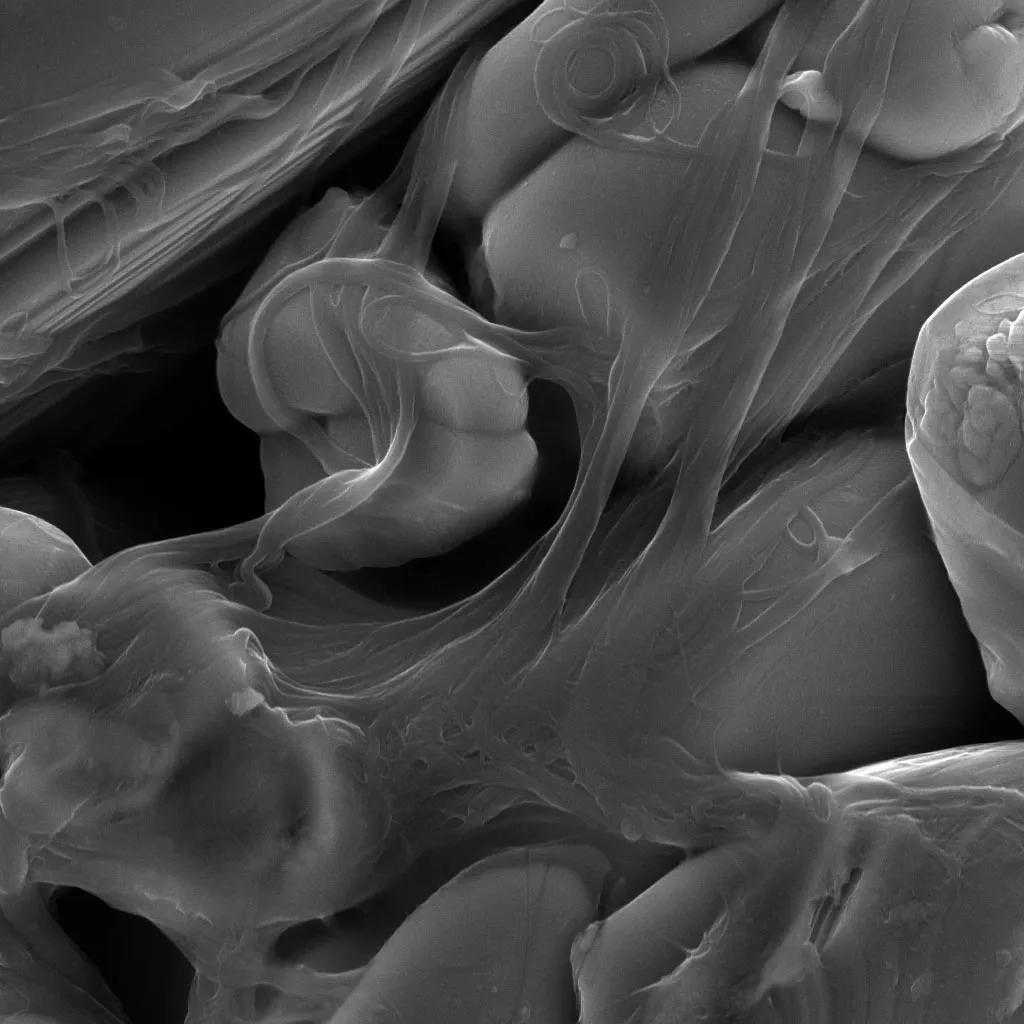

TUBALL™ BATT NMP is an ultrafine TUBALL™ nanotube dispersion in NMP for high-energy cathodes. TUBALL’s unmatched conductivity enables improved battery safety and energy density. TUBALL™ BATT is now available in an optimized, more cost-efficient dispersion form.

To buy nanotube products, please contact us. Price depends on the required volumes.

Material system

High energy cathodes (ex. NCM 811, NCM 622, NCM 523, NCA, LCO, LFP)

Сoncentrate carrier

NMP, PVDF, others

Shape

Suspension

Benefits

Boosted energy density

Thanks to 10–60 times lower loading of conductive additive, up to 98.8% active material content possible in dry electrode

Higher safety

Increased safety due to halved battery resistance increase (DCR)

Higher discharge power

>50% higher at high discharge rates

Improved adhesion

Doubled thanks to the bond strength between cathode particles

Documents

Also available in:

English

TDS TUBALL BATT NMP 0.4% 02NM23 ENG V06.PDF

PDF102.4 kB

TDS TUBALL BATT NMP 1% 02NM29 ENG V04.PDF

PDF204.8 kB