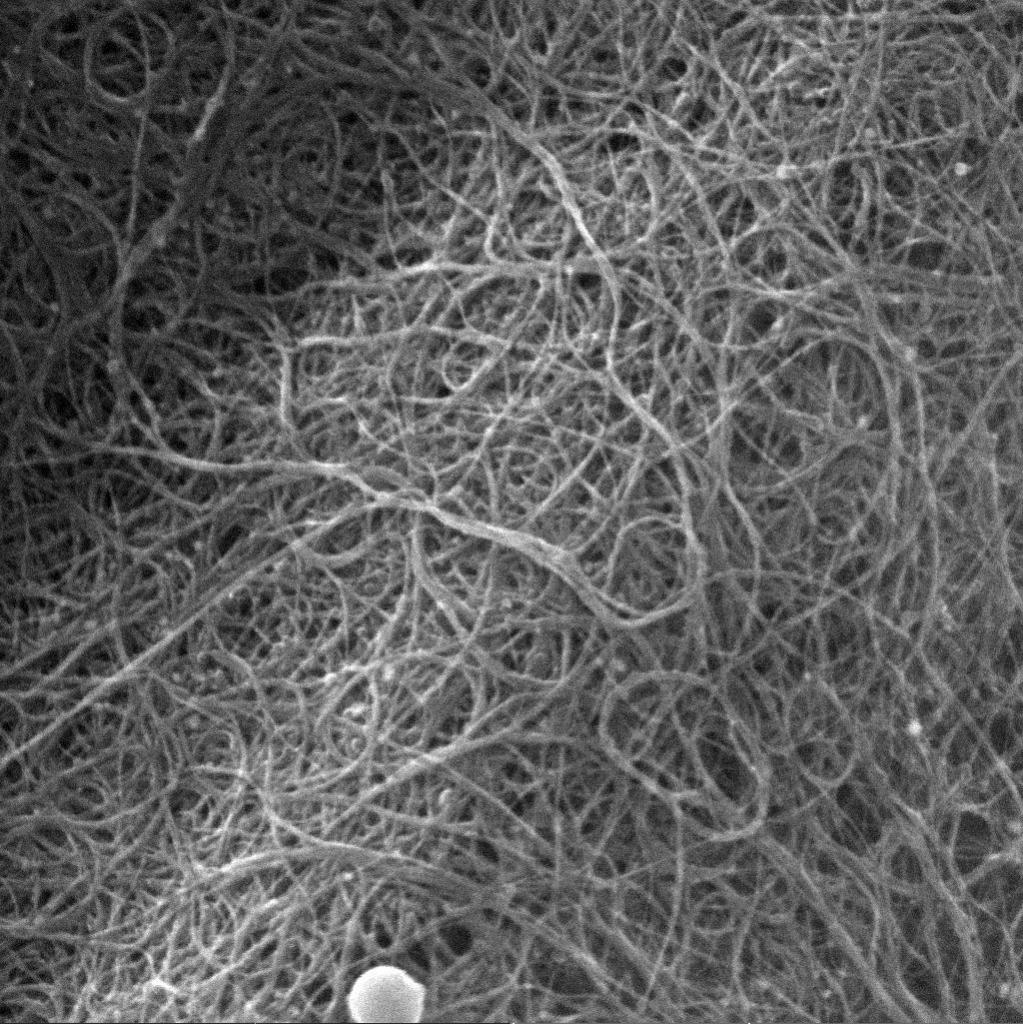

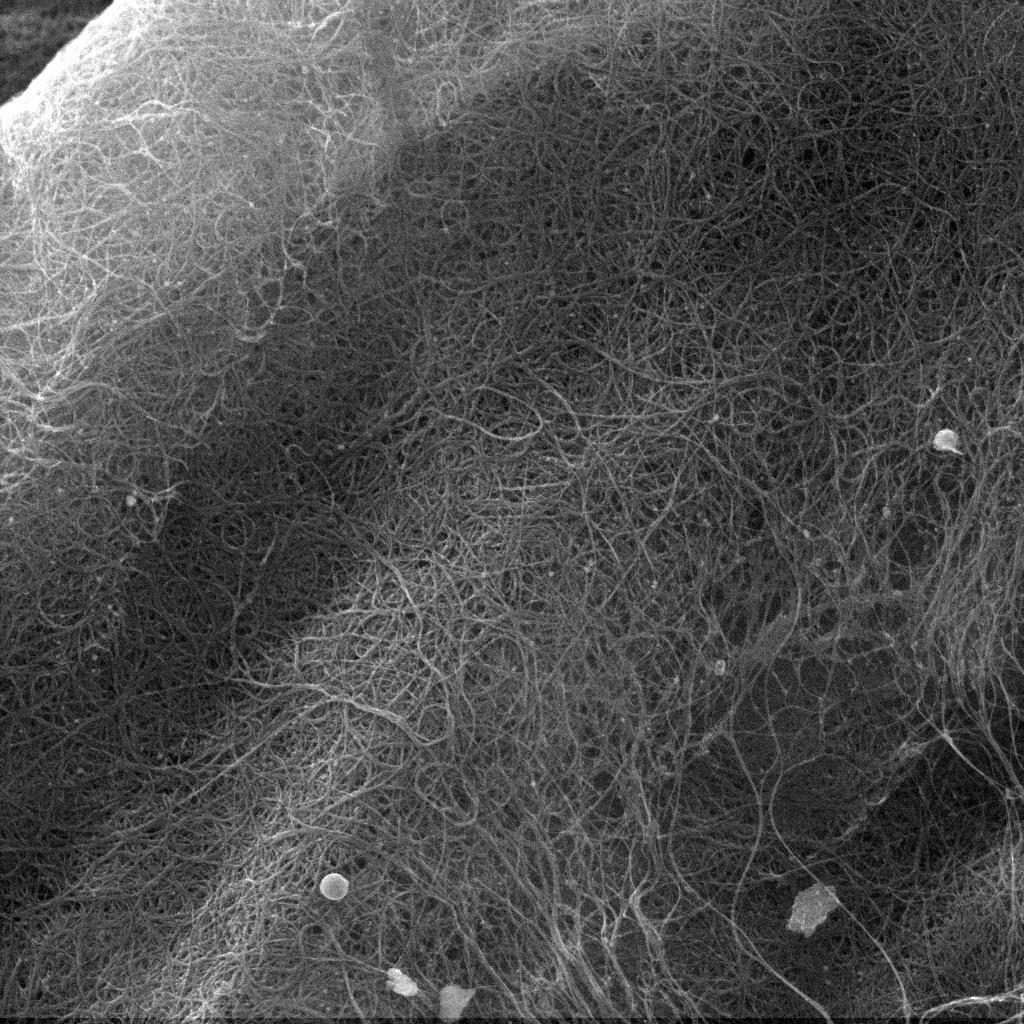

The highest purity and the most cost-effective graphene (single wall carbon nanotubes) nanotubes on the market. Get TUBALL™ nanotubes concentrate now for required conductivity, durability, mechanical strength, and color of your material. The superiority of TUBALL™ SWCNT to other additives comes from its ultra-low working dosage and unique combination of properties, including high conductivity, mechanical strength, and flexibility.

Produced by OCSiAl in tens of metric tons annually with unlimited scalability potential. The cost of our SWCNT products depends on the quantity ordered. Please reach out to us for a personalized quote.