Graphene nanotubes for PVC-plastisol: electrical conductivity with preserved mechanical properties and light colors

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, a line of anti-static masterbatches based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

TUBALL™ graphene nanotubes, also known as single wall carbon nanotubes, can be used in the production of PVC plastisol systems in compliance with the following standards and recommendations: ANSI/ESD STM2.1, Directive 1994/9/EC and ATEX Directive 95, EN 1149, EN 61340, EN 16350, etc.

Anti-static PVC plastisol systems with TUBALL™ nanotubes are widely adopted for:

- Textiles

- Ventilation ducting

- Mesh for mining applications

- Conveyor belts, including treadmill belts

For PVC-plastisol systems, TUBALL™ MATRIX 814 should be used.

|

Target system |

PVC-plastisol systems |

|

Additive carrier |

Mixture of epoxidized soybean oil and polymeric stabilizing agent |

|

Product |

|

Benefits provided by TUBALL™ MATRIX for PVC-plastisol:

- Ultralow dosage starting from just 0.05 wt.% TUBALL™ graphene nanotubes*

- Maintains good balance of mechanical properties

- Permanent, stable, uniform electrical resistivity without “hot spots”

- Can be applied with various fabrication technologies: dipping, molding, coating, and others

- Allows production of conductive parts that retain colors

- Low dosage gives greater flexibility in the final formulation

- Ease of application and low dosage makes logistics less complex and more efficient

- Production without carbon dust

*Dosages may vary depending on the formulation, processing, and products.

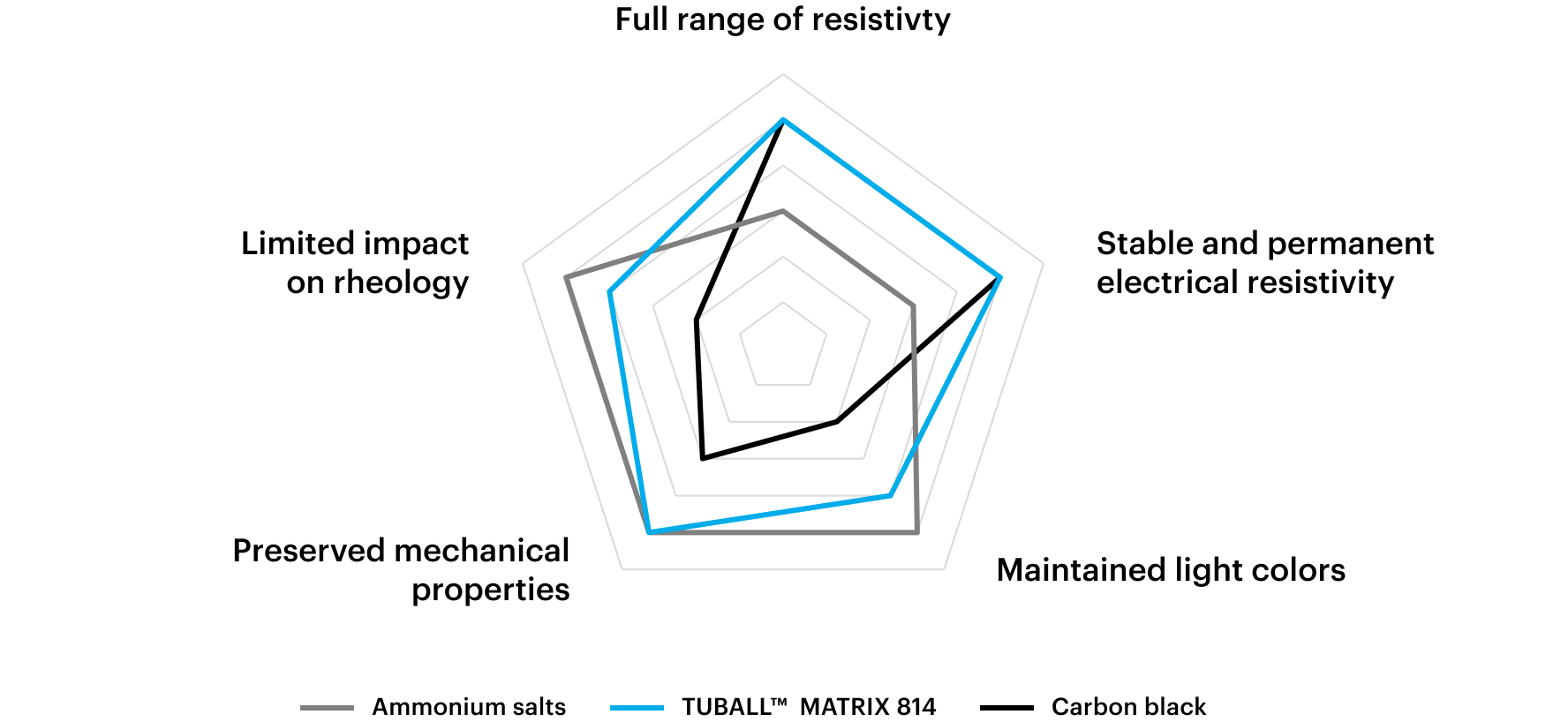

TUBALL™ graphene nanotubes are a versatile conductive agent offering strong performance on all key parameters

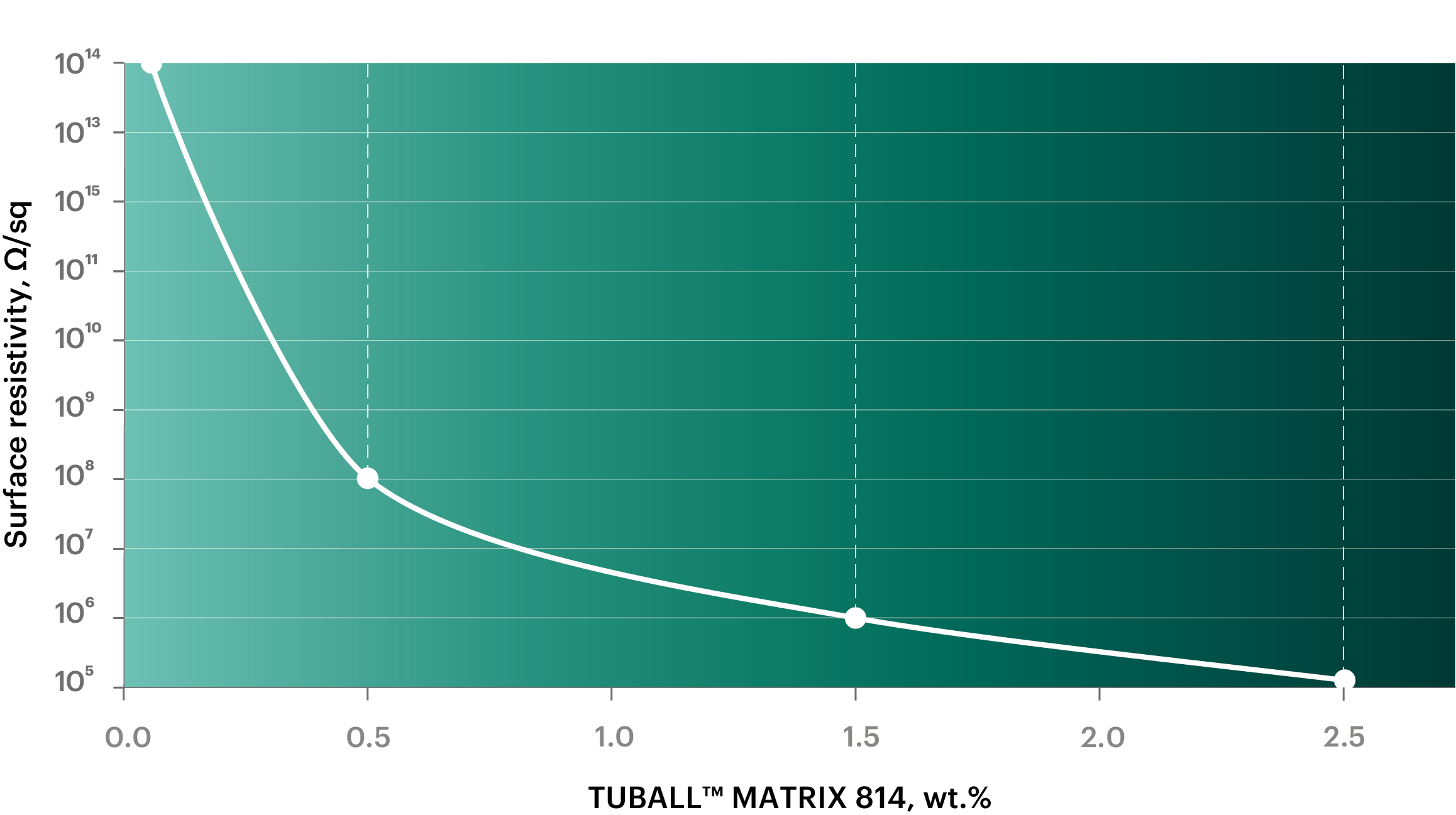

Full range of resistivity while preserving colors

TUBALL™ MATRIX 814 provides a full range of electrical resistance of 104–109 Ω, while allowing for a wide range of colors to meet customer requirements.

OCSiAl internal PVC-plastisol formulation. Sample thickness: 2 mm. ASTM D257

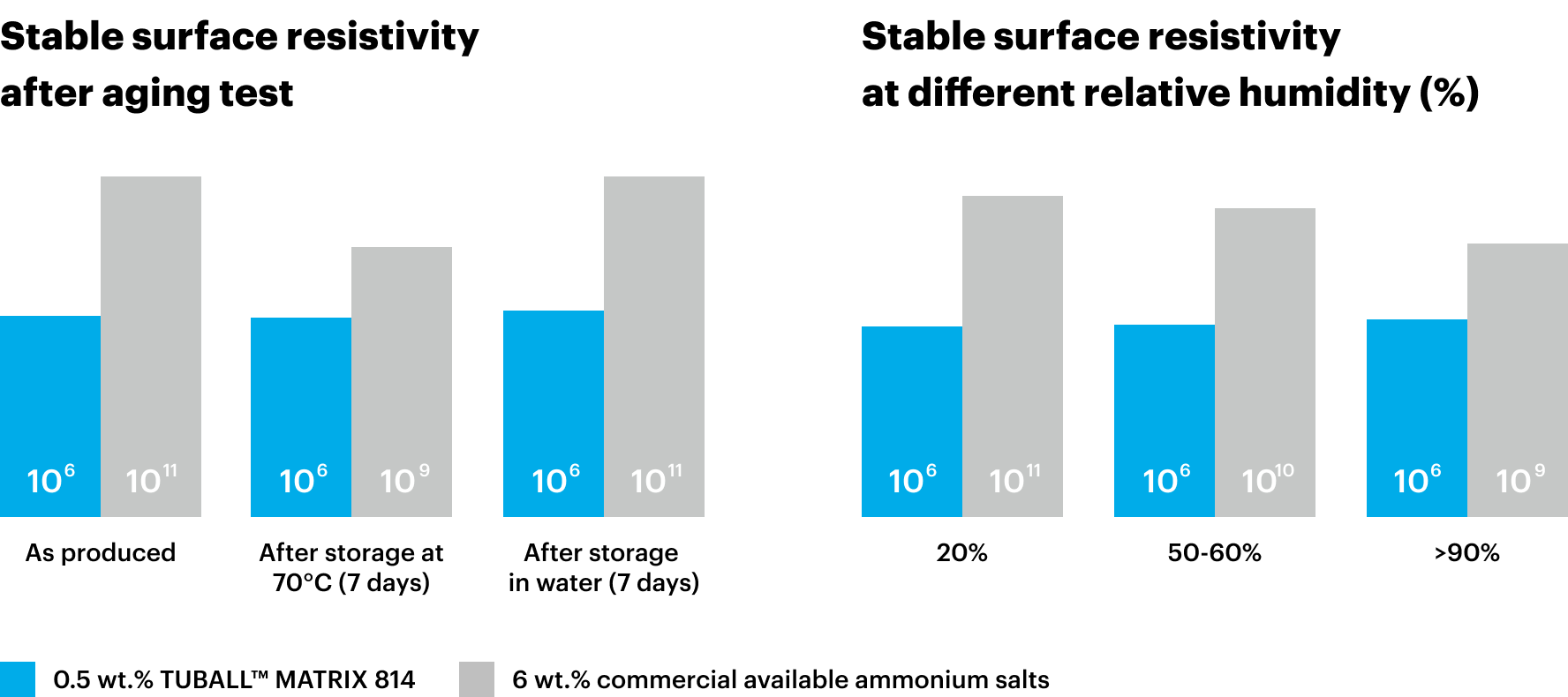

Stable, permanent electrical resistivity

TUBALL™ MATRIX 814 provides a permanent and stable level of electrical resistivity independent of storage conditions or humidity.

OCSiAl internal PVC-plastisol formulation. Surface resistivity Ω/sq, ASTM D257

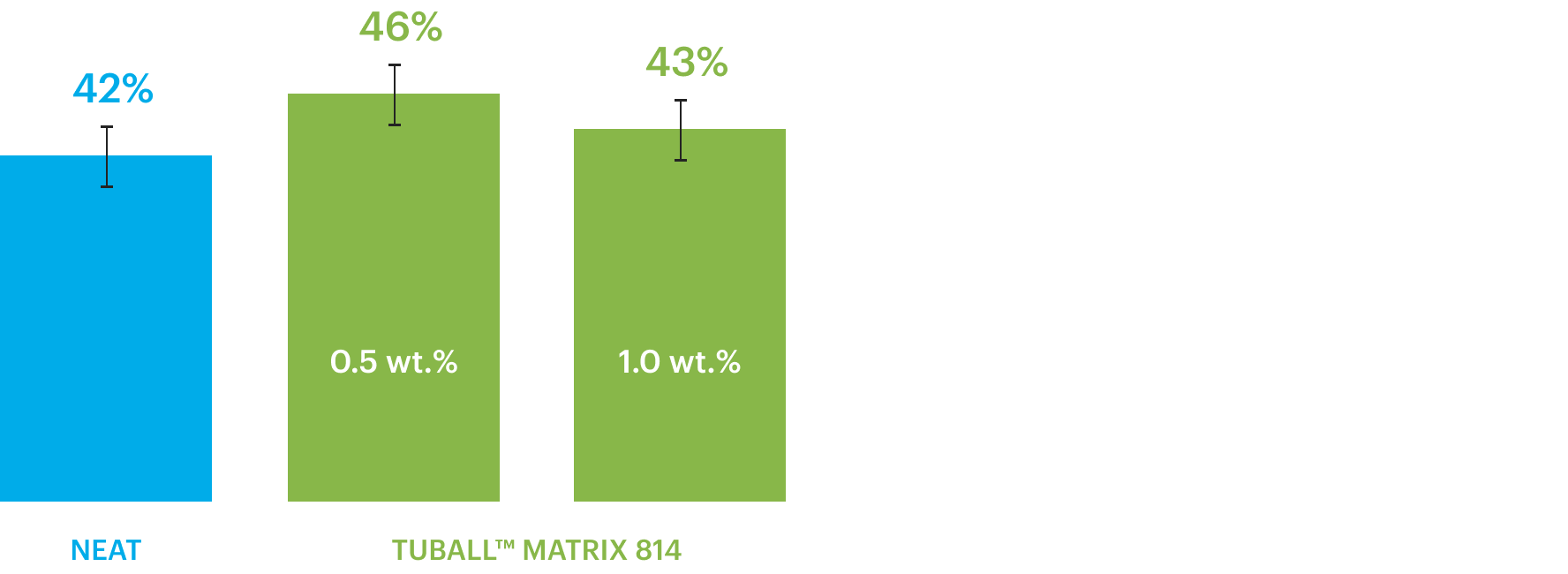

Preserved mechanical properties

TUBALL™ MATRIX 814 maintains and even improves the mechanical properties of conductive PVC-plastisol compounds.

Maintained abrasion resistance index

OCSiAl internal PVC-plastisol formulation. ASTM D5963-04

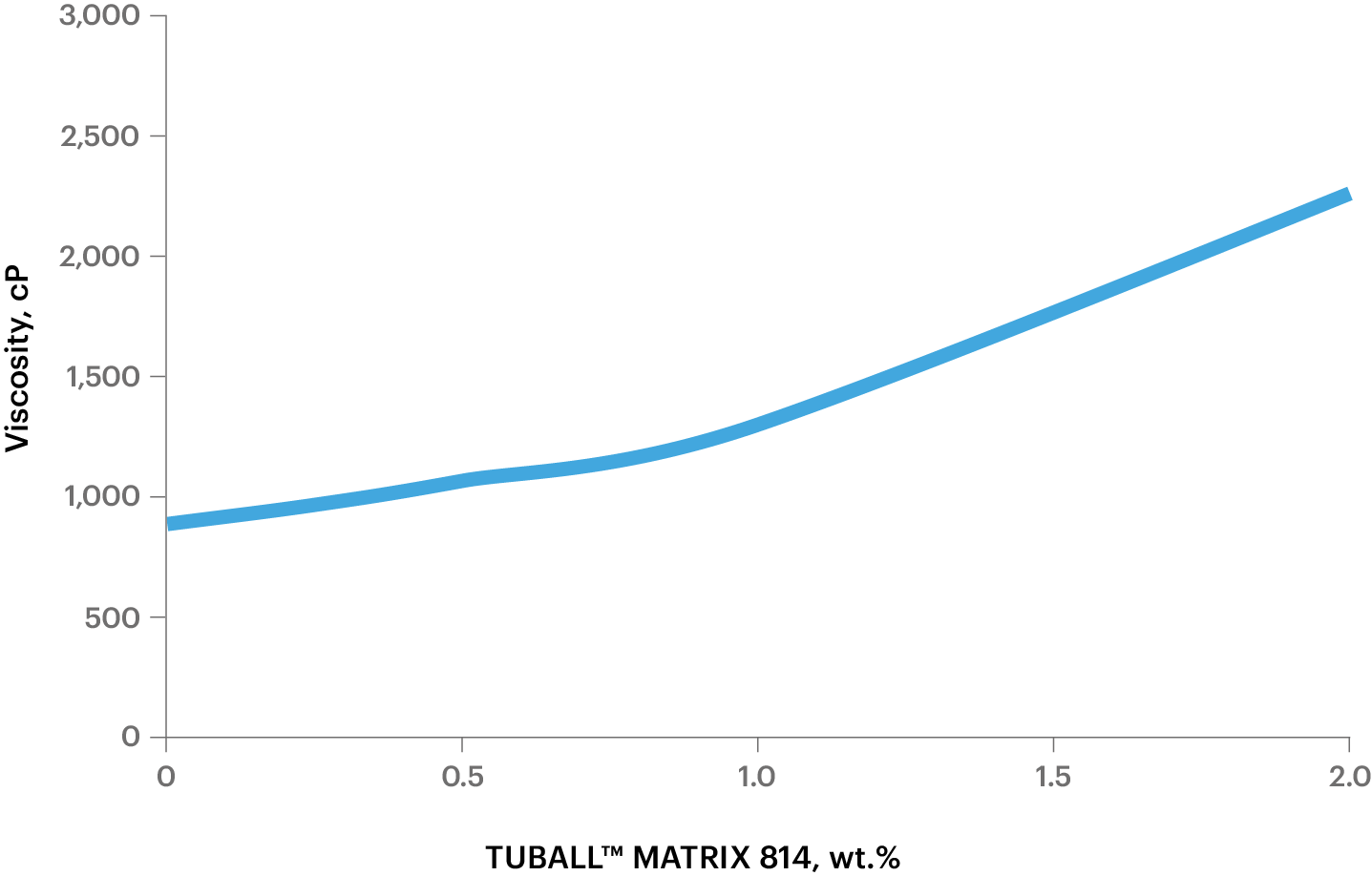

Limited Influence on viscosity

*OCSiAl internal PVC plastisol formulation. Brookfield DV2T viscometer, spindle RV-06, 50 rpm at 25°C

0.5–2.0 wt.% TUBALL™ MATRIX 814 generally leads to acceptable increasing of viscosity for PVC plastisol processing.

Application case

PVC Plastisol-based Textile

PVC Plastisol-based Flexible Ventilation Ducting

Treadmill belts

Pay close attention to the processing guidelines for TUBALL™ MATRIX 814

Download PDF version:

Additional information

Electrical conductivity for PVC plastisol

Convey with less product damage using anti-static belts

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample