Guaranteed conductivity of epoxy coating without compromising color and performance

Obtain the required level of electrical conductivity in your coating formulation, but preserve its color, surface, rheology and mechanical performance – all starting with only 0.1% of graphene nanotube concentrate as a conductive additive.

OCSiAl is a global leading manufacturer of graphene nanotubes branded TUBALLTM.

To simplify industrial use of nanotube , the company develops and produces TUBALLTM MATRIX – graphene nanotube concentrates. TUBALLTM MATRIX demonstrates a consistent quality for large industrial batches.

FULL RANGE OF CONDUCTIVITY COMBINED WITH COLOR

Even ultra-low loading rates of TUBALL MATRIX are enough to create a dense conductive network that is 100% guaranteed protection against insulative zones or “hot spots”.

In contrast to the high loading rates of standard conductive agents required to target the same resistivity level, using graphene nanotube concentrates allows you to give your final products a wide range of colors.

.png)

MECHANICAL PROPERTIES AS OF NON-CONDUCTIVE EPOXY

Thanks to their unique morphology and low loading rates, graphene nanotubes allow the mechanical properties and rheology of the original compound to be preserved. These parameters are usually sacrificed when using carbon black or carbon fiber, which require much higher loadings.

Preserved adhesion

ISO 2409. No detachment of coating from substrate after cross-cut adhesion test. The same 0 class adhesion in epoxy-polyester system after addition of TUBALLTMMATRIX

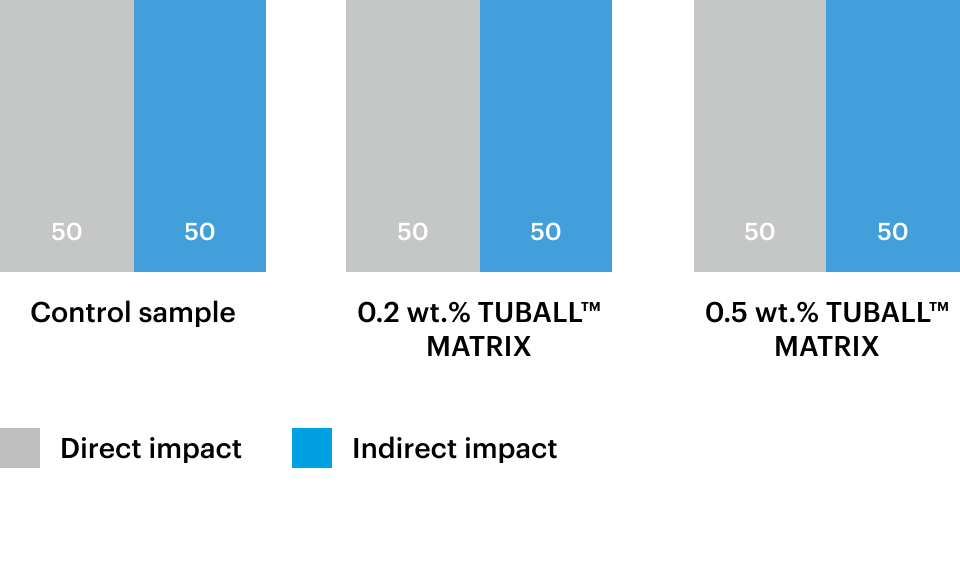

Maintained impact resistance

ISO 6272. Hybrid epoxy-polyester system. Full resistance to falling 1kg weight indenter impact from 50cm height directly to the coating and from the opposite side

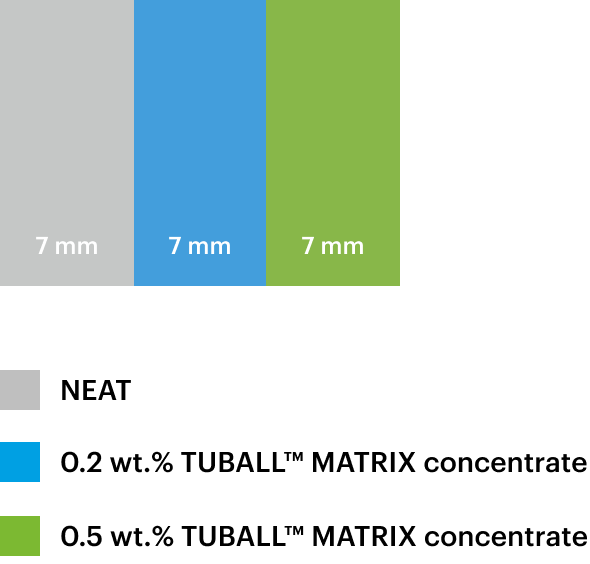

Retained resistance to cracking

ISO 1520. Hybrid epoxy-polyester system. Full resistance of coating to cracking and detachment from a substrate by indentation to 7 mm depth

THE BEST PRICE OF CONDUCTIVE PROPERTIES

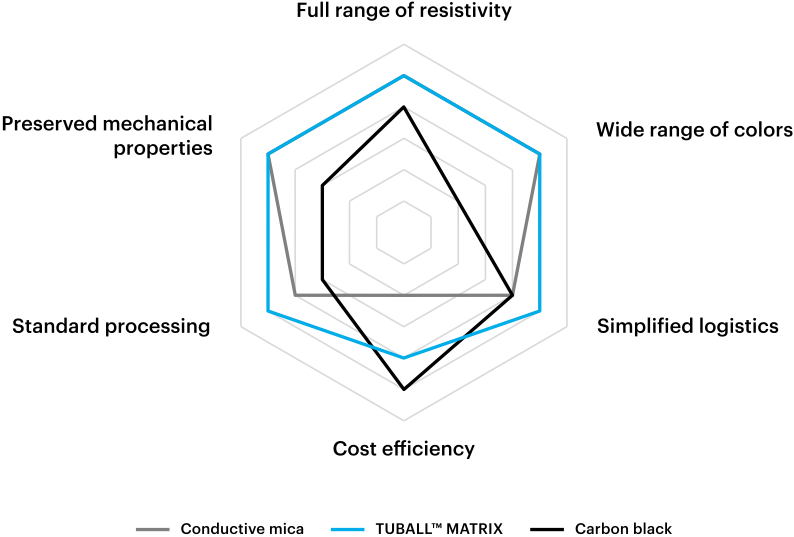

Graphene nanotubes guarantee the same properties as conductive mica, but at lower price, leading to the best cost-performance ratio.

Replacing other standard conductive agents with graphene nanotube concentrates can also lead to cost cuts for final products manufacturers. For example, ESD floors installers can reduce the thickness of coating and use less epoxy, while tank lining producers can decrease the number and duration required for visual inspections of conductive coating.

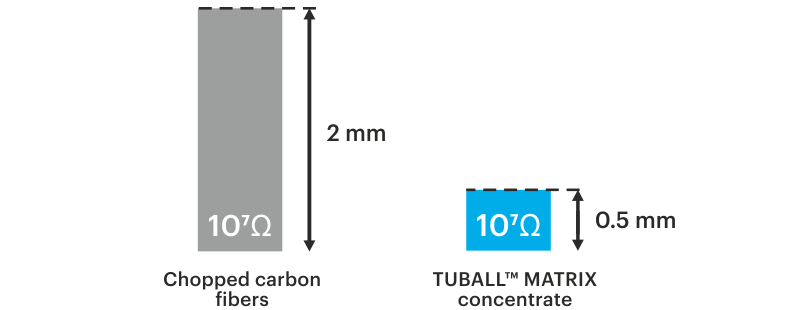

Comparison of the minimum base coat thickness with different conductive agents required for the same resistivity level

EASY-TO-APPLY NANOTUBE CONCENTRATES

OCSiAl has developed a line of industry-friendly TUBALL MATRIX nanotube concentrates that are mixed directly with epoxide coating. No additional equipment or formulation change required.

Standard single-shaft high speed mixer

25 min total dilution time

Instant quality control with a grindometer to reach particle size ≤ 15 um

Please choose the right product for you to test or contact us for assistance:

OCSiAl produces TUBALL graphene nanotube concentrates for anti-static epoxy and polyurethane flooring that make it easier to apply nanotubes in a standard manufacturing process. Request a sample of nanotube concentrate that suits your ESD flooring formulation

WIDE RANGE OF APPLICATIONS

TUBALLTM MATRIX has been adopted by a number of industries, including ESD self-leveling flooring, tank and pipe linings, and powder coatings. Check the business cases below or create your own by ordering a sample of nanotube concentrate.

Сonductive Epoxy Coating

Epoxy Powder Coatings

Lining Coating

Contact us to discuss your project specifications or to request a TUBALL MATRIX sample.