Flooring / EU / Top Choice (ENG)

Author: Philippe Bichot

3 minutes read

THE BEST CHOICE FOR AN ANTI-STATIC AGENT FOR STATIC DISSIPATIVE FLOORING

Do you always have to compromise between the performance of your conductive filler and its price? Use of carbon fiber and ATO leads to poor quality ESD floors, while mica is too expensive. Spend 3 minutes to find out why you should replace your agent with TUBALL™ graphene nanotube concentrate and how it will reduce your costs.

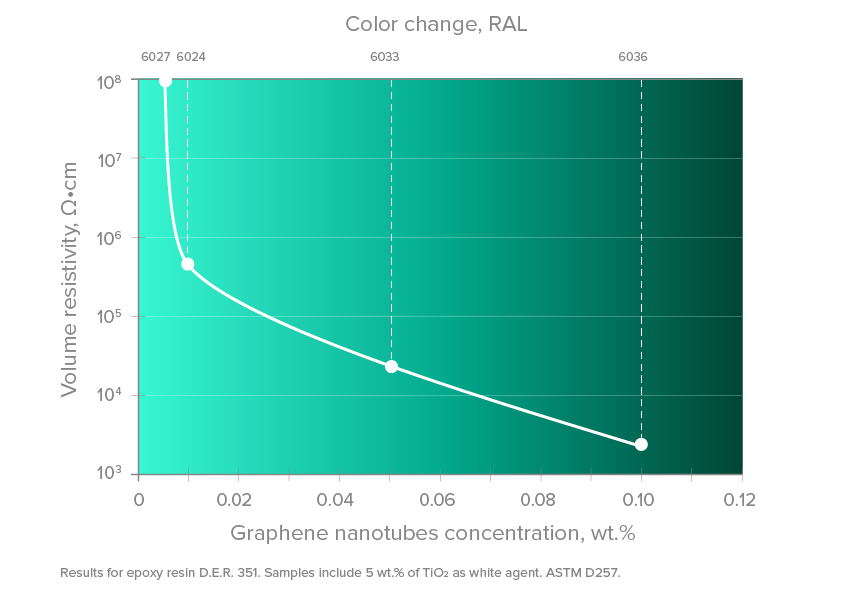

FULL RANGE OF RESISTIVITY WITH PRESERVED COLOR

AS A RESULT OF LOW WORKING DOSAGE REQUIRED

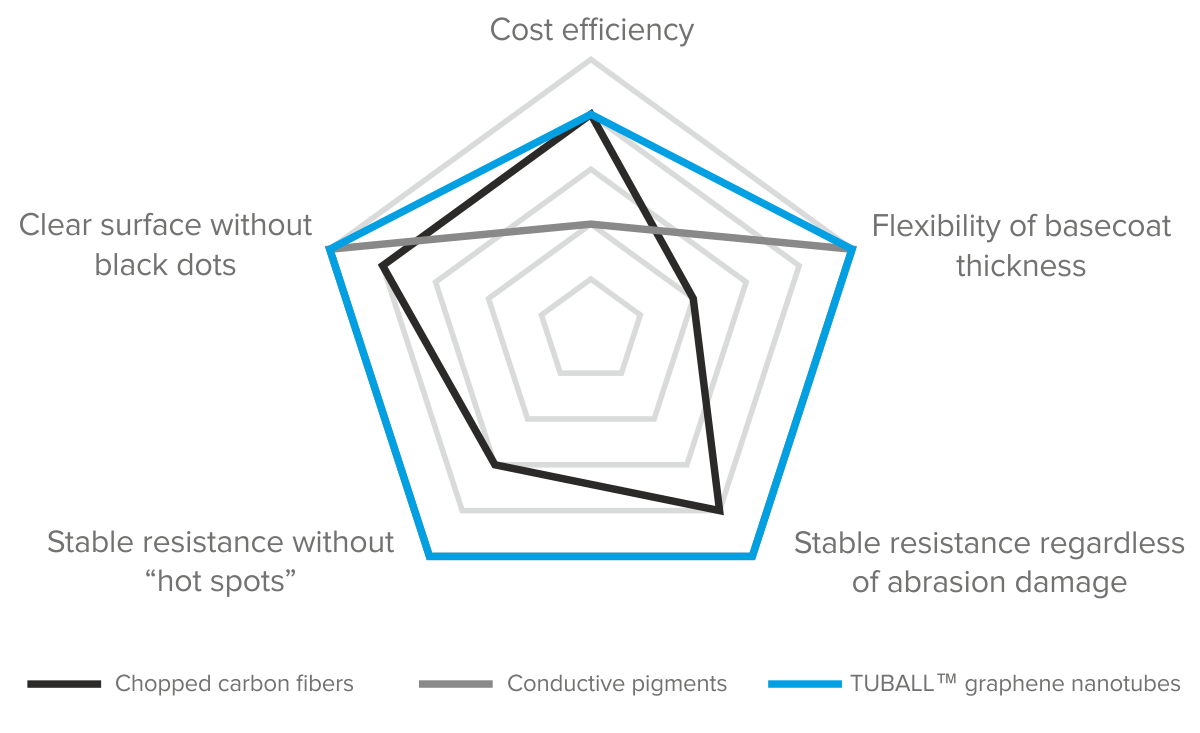

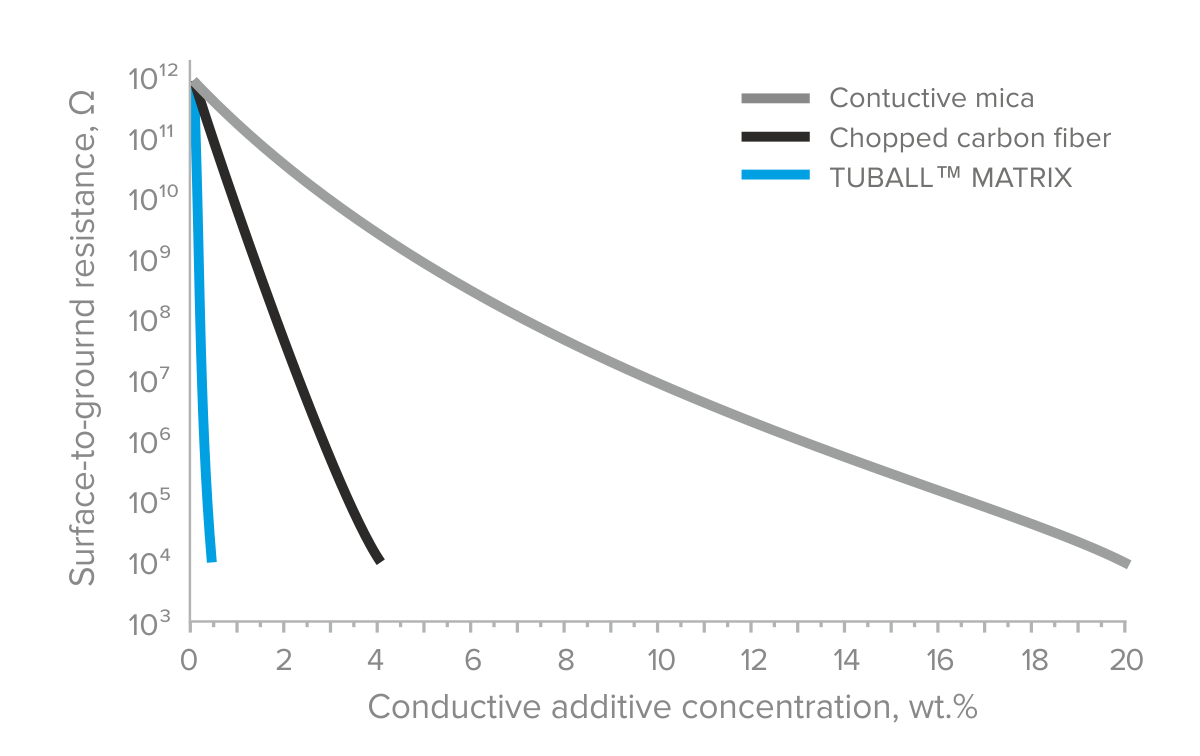

Compared with chopped carbon fiber and conductive mica, TUBALL nanotubes make it possible to obtain the required conductivity at much lower working dosages. There is no other conductive filler able to reach the targeted level of conductivity at such low dosages:

Even 0.01–0.04 wt.% of nanotubes is enough, while it minimally effects the color of the anti-static floor:

COST REDUCTION AS A RESULT OF REDUCING BASECOAT THICKNESS OR TAKING AWAY CONDUCTIVE PRIMER

Because of the length of chopped carbon fiber (2 mm or longer), the thickness of the base layer must be at least as much (~2 mm). This can result in difficulties in the installation process, increased costs, and the possibility of occurrence of insulating “hot spots”. In contrast, TUBALL can be used in different flooring systems and at different thicknesses, always showing a strong performance.

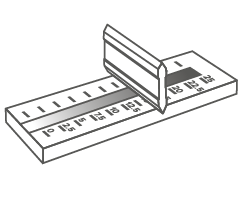

EASY-TO-APPLY AS A RESULT OF INDUSTRY-FRIENDLY CONCENTRATES

OCSiAl has developed a line of concentrates that make it easier to apply nanotubes with standard equipment widely used in the coating industry and with no changes to the original formulation.

|  |  |

Standard single shaft | 25 min total | Quality control |

Other benefits provided by TUBALL™ nanotubes for anti-static flooring:

• The unique properties of graphene nanotubes lead to improved abrasion resistance of flooring;

• Low dosage gives greater flexibility in the final formulation;

• The easy application and low dosage required make logistics less complex and more efficient.

| Parameter | Chopped carbon fiber | Milled carbon fiber | ATO | Graphene nanotubes |

|---|---|---|---|---|

| Working dosage | 1—4 wt. % | 1—10 wt. % | > 10 wt. % | 0.01—0.04 wt. % |

| Resistance range (surface to ground) | 1011-104Ω | |||

| Black dots on surface | possible | yes | none | none |

| Available color range | wide | limited | limited | wide |

| Floor thickness | min 2 mm | min 0.5 mm | up to 16 mils | >any |

| Resistance remains stable after abrasion defects on surface | problematic | yes | yes | yes |

| Influence on mechanical perfomance | small negative | strong negative | small negative | none |

| Influence on rheology | small negative | strong negative | small negative | acceptable |

| "Hot spots" (resistance varies on surface) | possible | possible | possible | none |

| Stable resistance over time | yes | yes | yes | yes |

| Settling during storage | possible | possible | yes | minimal |

| Cost of anti-static property | acceptable | acceptable | high | acceptable |

BUSINESS CASE: GRAPHENE NANOTUBES

IN STATIC DISSIPATIVE FLOORINGS

When a smart vehicle manufacturer needed a new ESD floor for their production facility, they turned to an ESD flooring manufacturer with a self-leveling epoxy powered by TUBALL graphene nanotubes, produced by OCSiAl.

Using just 0.01% of nanotubes by weight, the ESD floor achieved 107 Ω resistance to ground and provided greater control over the floor’s color and finish.

Walking voltage tests performed following installation confirmed discharge voltages across the floor were less than 10 volts, assuring compliance with the ANSI/ESD S20.20 standard.

Request a sample of TUBALL MATRIX that suits better to your formulation

If you have any questions or need assistance with choosing the most effective graphene nanotube solution for your compound, please contact our experts.