Carbon nanotube products

Embalaje

Tarro 0.6 l (hasta 250 g)

Otros tamaños de embalaje están disponibles a petición del cliente

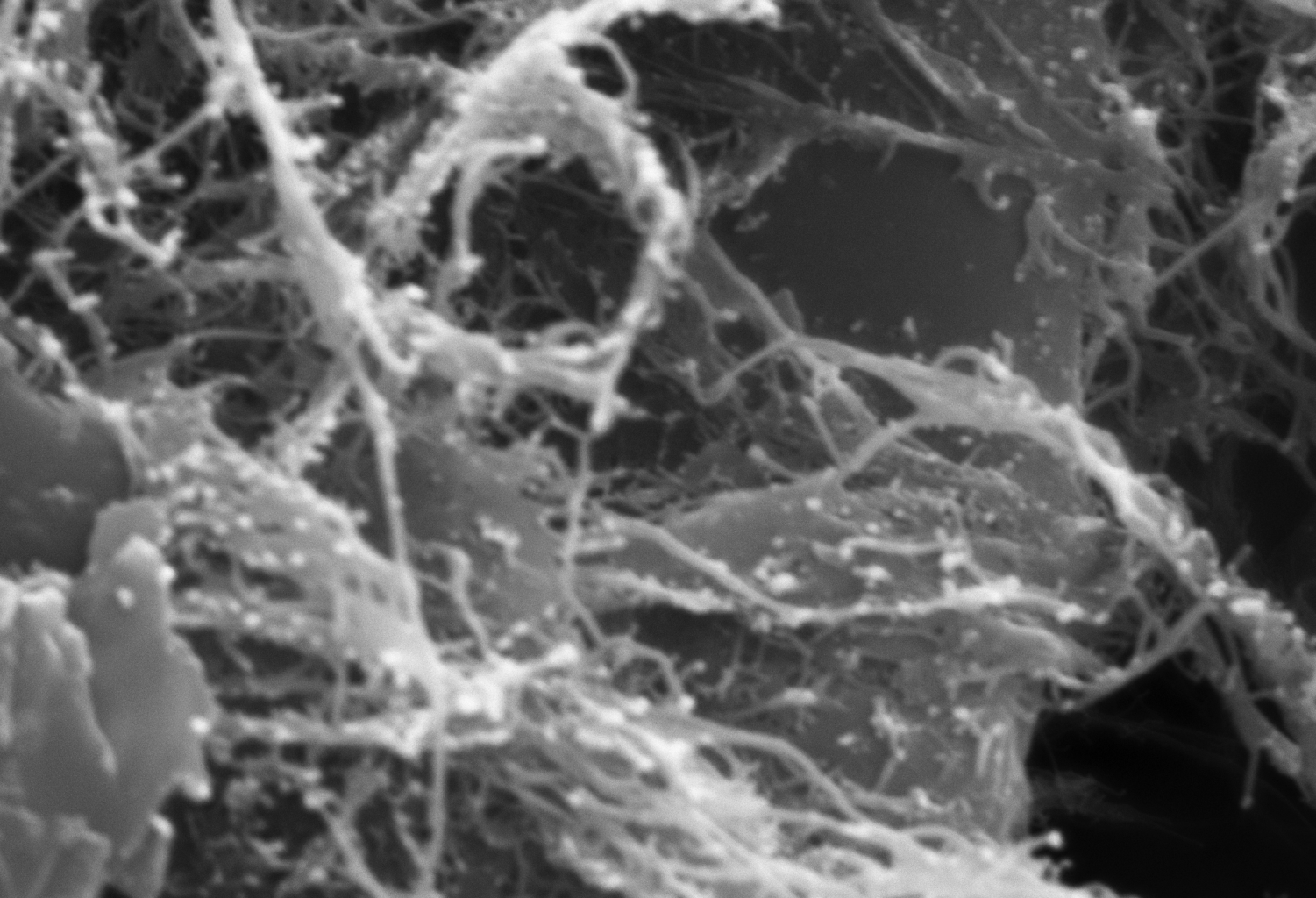

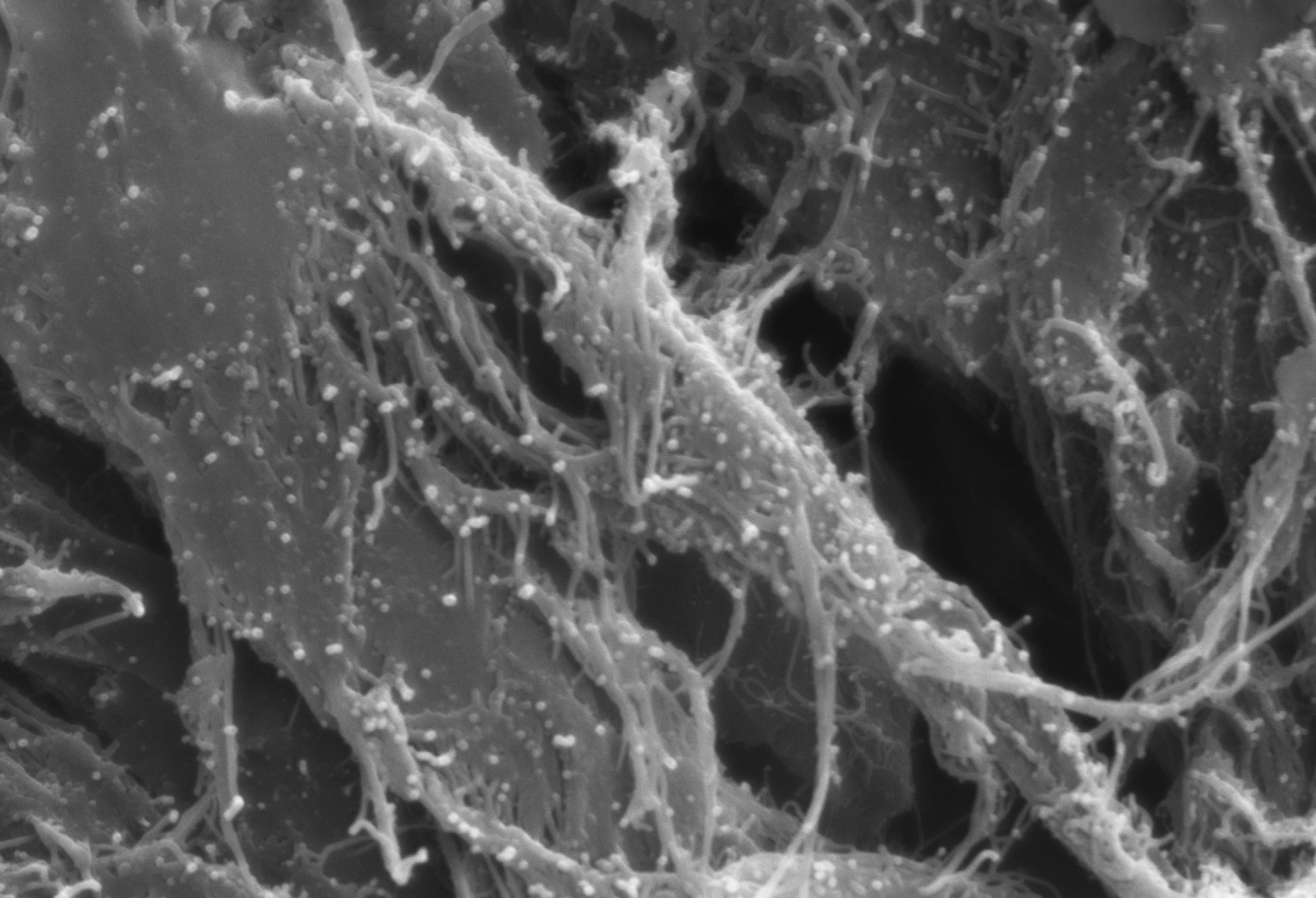

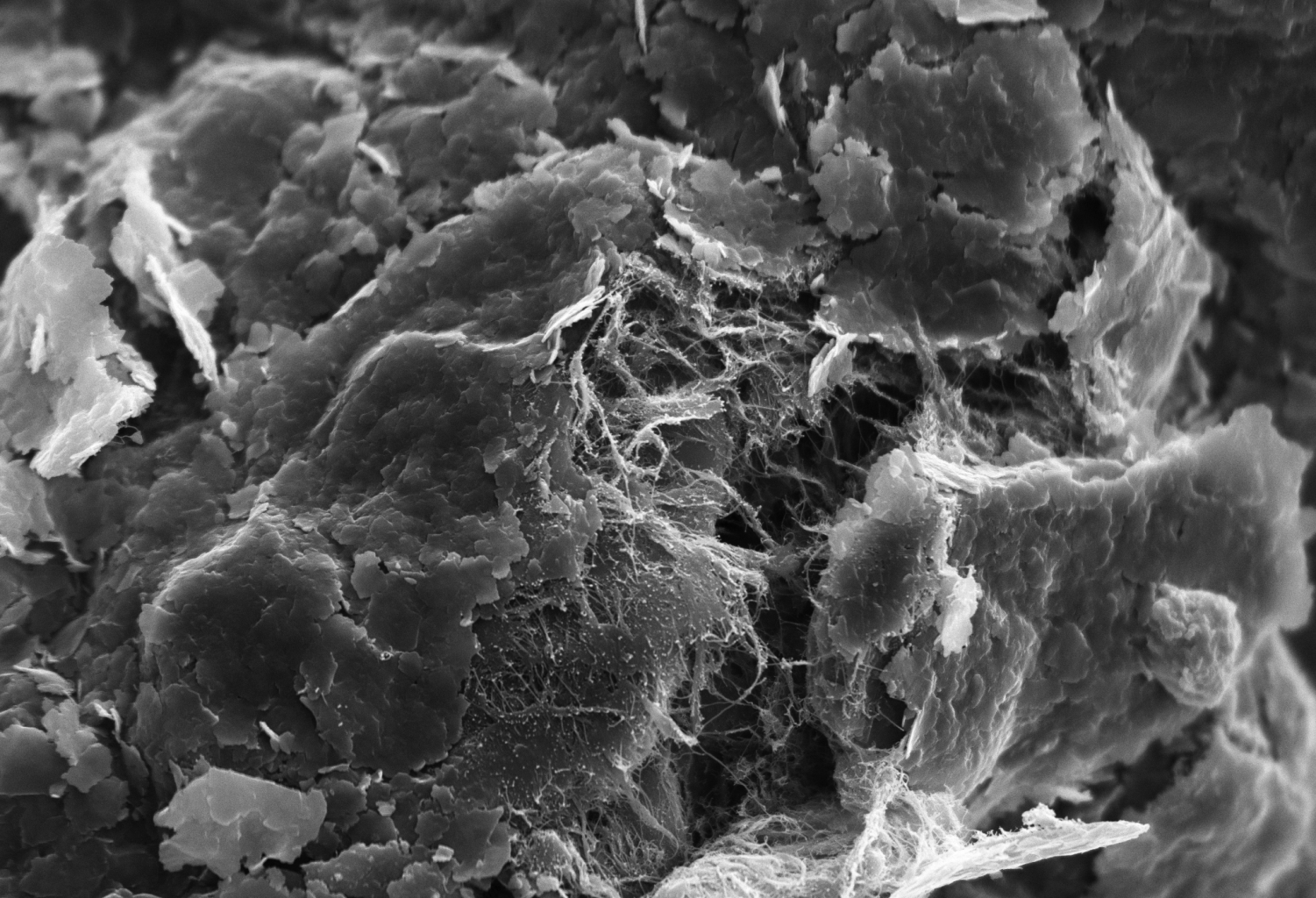

Aditivo conductivo basado en un plastificante con un agente estabilizador para recubrimientos epoxi y PU con disolvente sin afectación en el color y las propiedades mecánicas

Materiales del sistema

Base disolvente de resinas epoxi y de poliuretano

Dosis operativa

0.1–1% de peso

Matriz

Plastificante y agente estabilizante: éter alquil glicidílico, sal de amonio de derivados a base de poliolefinas

Forma

Pastosa

Ventajas

Conductividad eléctrica

Garantiza una conductividad eléctrica permanente y uniforme sin "puntos calientes"

Características permanentes

Propiedades antiestáticas que no dependen de la humedad

Propiedades mecánicas

Conservación y mejora de las propiedades mecánicas

Disponibles en muchos colores

Da color a la resina de epoxi gracias a que los aditivos son aplicados en bajas concentraciones y a un efecto grisáceo mínimo

Conservación de la viscosidad

Influencia mínima sobre densidad, viscosidad y otras propiedades reológicas del material

Facil aplicación

Fórmula de predispersión que permite usar los equipos estándares de producción

Ejemplos de aplicación

Revestimiento interno de depósitos

Pulse para ver todos los casos

Vídeo

TUBALL™ MATRIX – Manual de aplicación (eng)

Documentos

Disponible en lenguas :

English

TDS TUBALL MATRIX 208 ENG V09.PDF

PDF307.2 kB

TUBALL MATRIX 200X 300X PROCESSING GUIDELINES ENG V04.PDF

PDF512 kB

TUBALL MATRIX 200X 300X PROCESSING KEY POINTS ENG V03.PDF

PDF8 MB