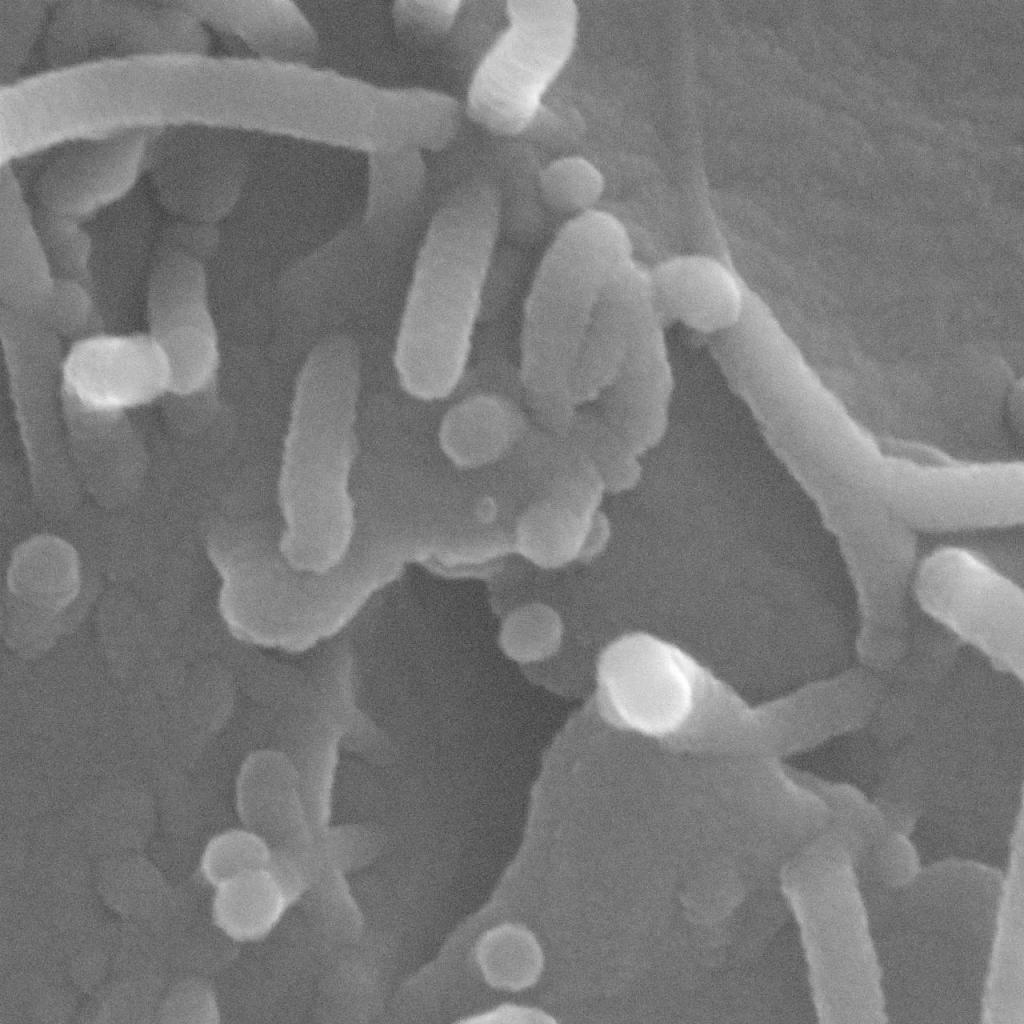

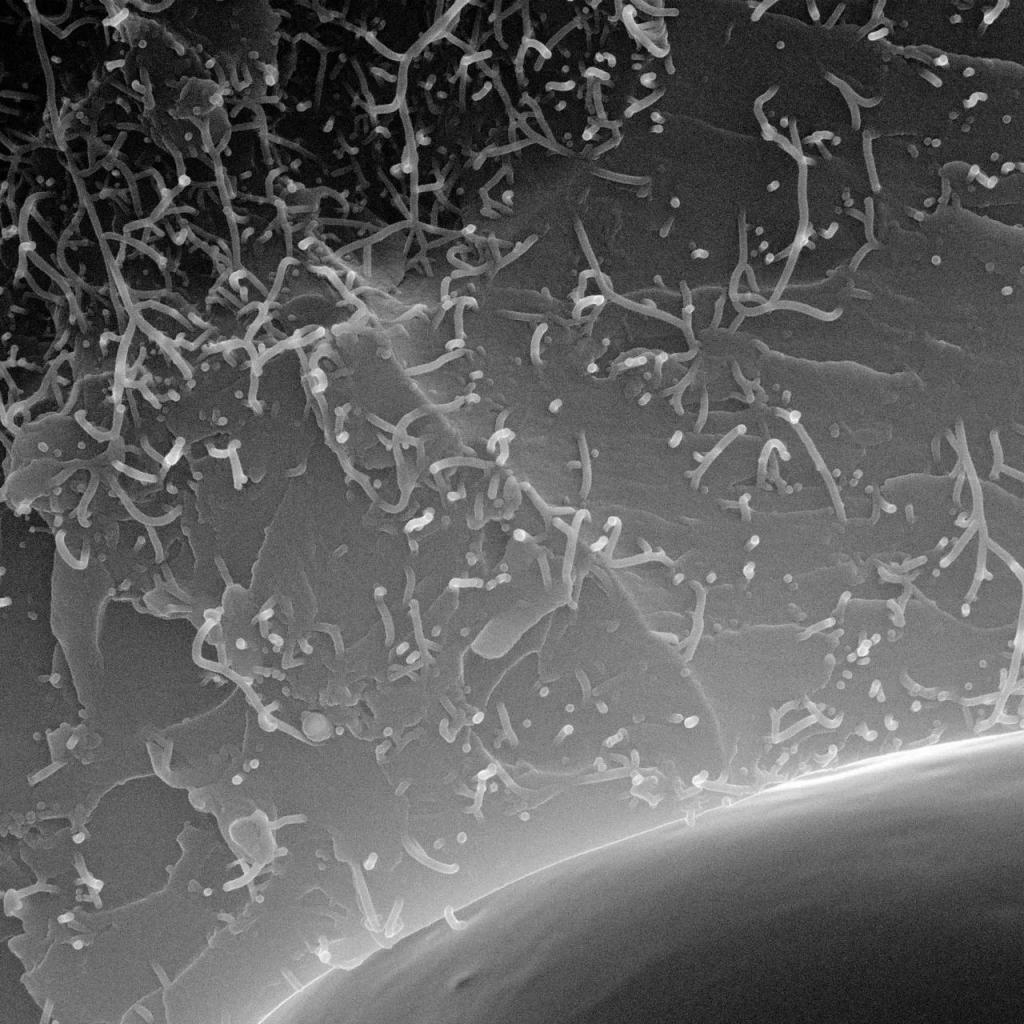

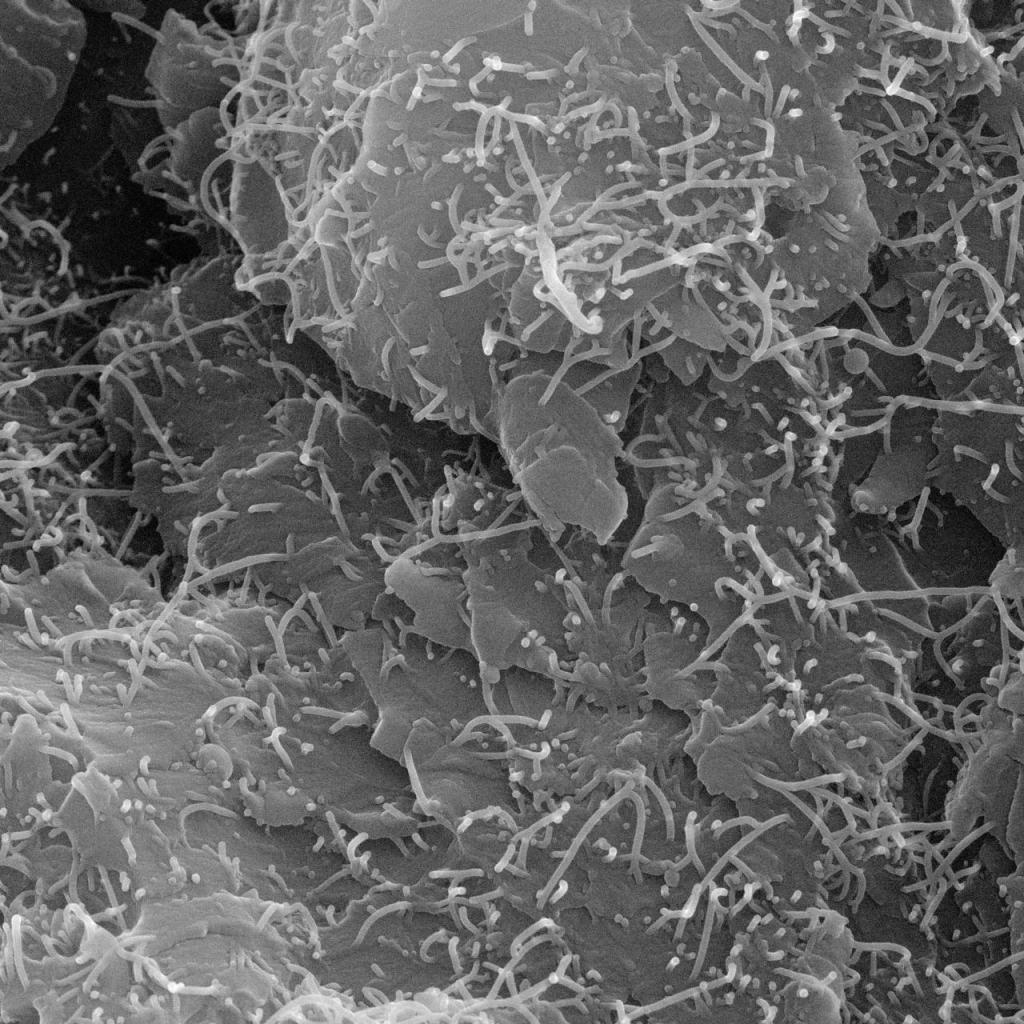

Aditivo conductivo basado en un surfactante para recubrimientos epoxi y PU sin disolventes y sin afectación en el color y las propiedades mecánicas. También se recomienda para los compuestos de epoxi.

Ventajas

Garantiza una conductividad eléctrica permanente y uniforme sin "puntos calientes"

Propiedades antiestáticas que no dependen de la humedad

Conservación y mejora de las propiedades mecánicas

Da color a la resina de epoxi gracias a que los aditivos son aplicados en bajas concentraciones y a un efecto grisáceo mínimo

Influencia mínima sobre densidad, viscosidad y otras propiedades reológicas del material

Fórmula de predispersión que permite usar los equipos estándares de producción

Ejemplos de aplicación

Mangas de impresión

Perfiles de cables de plástico de fibra de vidrio

Revestimiento en molde de poliéster

Vídeo

TUBALL™ MATRIX – Manual de aplicación (eng)

Anti-static and conductive hand layup composites: how to produce using graphene nanotubes