Conductive polyurethane rollers & sleeves: improved processing and safety performance

Conductivity in rollers and sleeves is required to prevent electrostatic charge and dust accumulation in packaging, printing, or converting processes, reducing production line stoppages and losses. Traditionally, carbon black and specific fillers were used for anti-static polyurethane rollers and sleeves, but the high concentrations of 10–15% of their total weight compromised strength, color, and product lifespan. Graphene nanotubes, an advanced anti-static agent, ensure safety, durability, and aesthetics. Even at ultralow concentrations, nanotubes provide stable conductivity and optimize the production cycle of sleeves and rollers.

Why does electrical conductivity matter in PU rollers and sleeves?

The industry often relies on standards to ensure quality, consistency, and safety in the production and use of rollers and sleeves. General standards cover aspects such as material properties, hardness, tensile strength, and other relevant characteristics. Even though there are no specific standards for conductivity in polyurethane rollers and sleeves, this property remains crucial for maintaining the safety and efficiency of various industrial processes.

In industrial environments, static electricity buildup can occur during manufacturing process. Electrostatic discharge (ESD) damages sensitive electronic components, leads to disruptions or degraded quality in manufacturing, and causes safety hazards. As well as avoiding these risks, conductivity helps to avoid static cling between the roller/sleeve and the materials being transported. This is particularly important in industries like printing, where the accumulation of static electricity can lead to misfeeds or defects in the printed material.

In digital printing or electrogravure printing, the conductivity of rollers is not only essential for preventing ESD but also for facilitating the transfer of ink to the substrate. In these processes, maintaining proper conductivity is integral to ensuring the efficiency and quality of the printing operation. In general, in various manufacturing processes, conductivity serves to guarantee the quality of end products and enhances the overall performance and longevity of components in diverse applications.

Challenges caused by traditional conductive agents

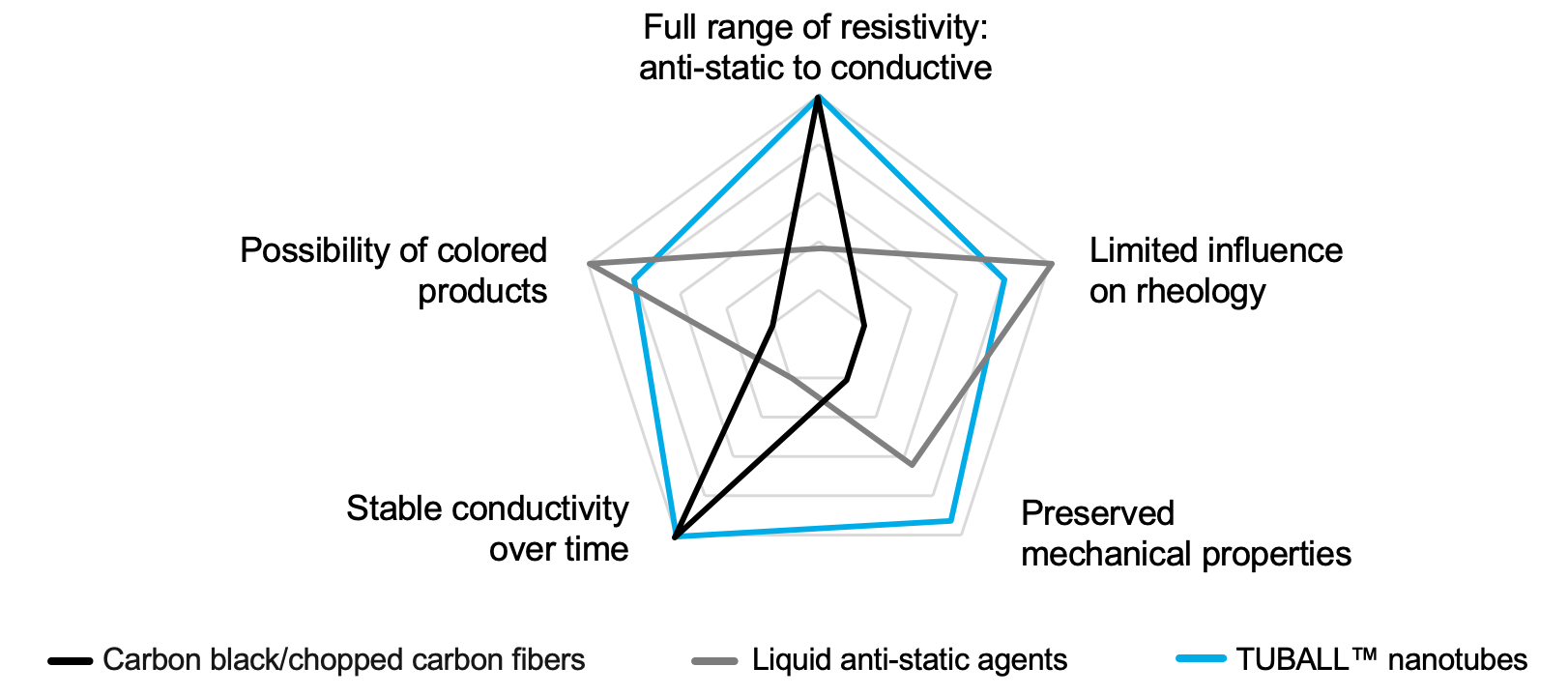

The structures of the sleeves and rollers are very complex and can comprise a range of materials: metal, pure polymer, or composites. Traditional additives like carbon black, chopped carbon fiber, or mineral/organic fillers have been utilized to introduce electrical properties to thermoset materials, especially polyurethane. However, these additives come with drawbacks. The required high concentrations of these additives, in the range of 10–15% of the total weight of the material, negatively impact rheology and mechanical properties leading to a loss of strength and reduced life cycle of products. Additionally, achieving light and bright colors in the final product becomes challenging. Liquid anti-static agents, while avoiding some of these issues, are limited in their conductivity range and can be affected by ambient humidity.

Increasingsafety of rollers and sleeves using graphene nanotubes

Graphene nanotubes, also known as single wall carbon nanotubes, are essentially single sheets of graphene rolled into long, flexible tubes. The exceptional properties of these nanotubes stem from their high length and extremely thin wall thickness of just one atom. Notably, graphene nanotubes exhibit outstanding electrical conductivity and boast impressive mechanical strength, measured in the terapascal range. Their ability to form a 3D network within polymers contributes to imparting conductivity to materials. These unique characteristics of graphene nanotubes make it possible to enhance electrical conductivity without compromising the production process or original mechanical properties of polyurethane.

Picture 1. This diagram provides average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

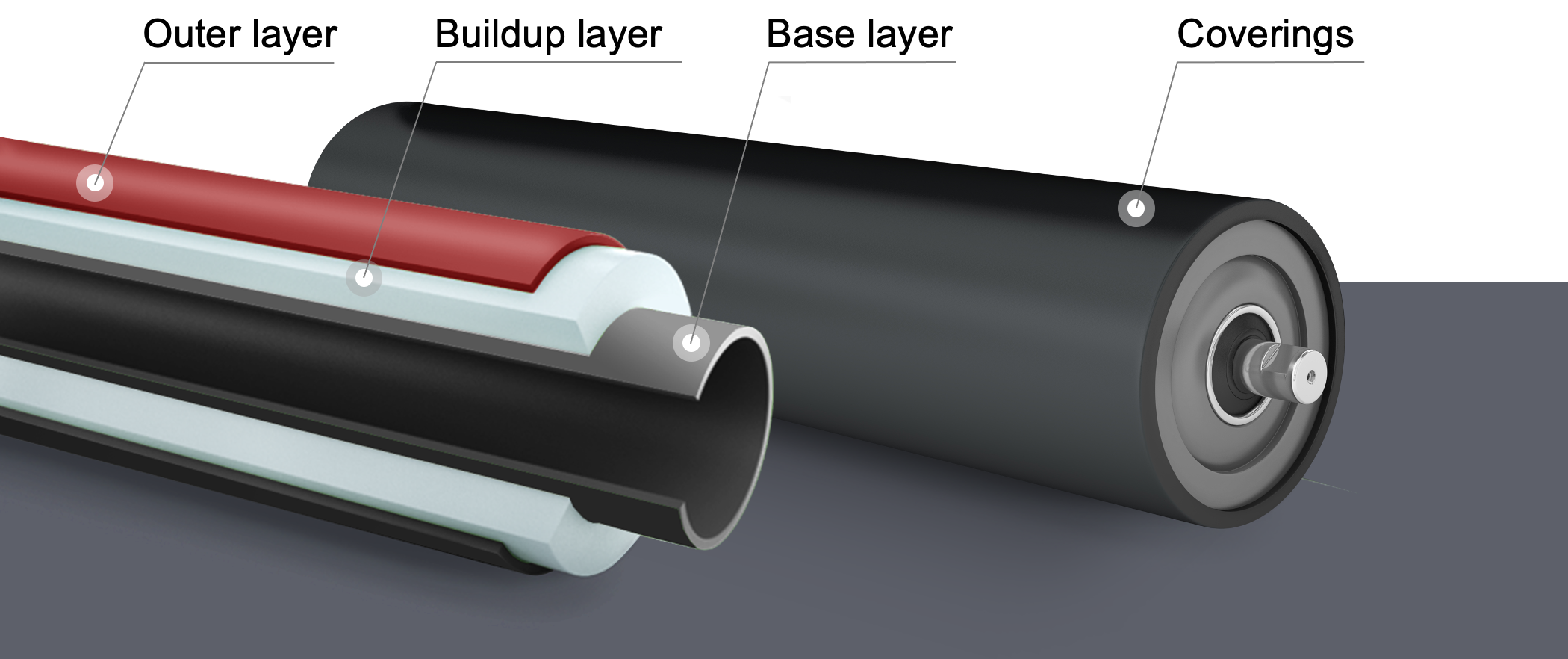

Furthermore, graphene nanotube-based solutions are so versatile that they can be used in any sleeve layer or roller covering to provide conductivity, whatever the material and the complexity of the structure.

Picture 2. Graphene nanotubes can improve all layers of PU rollers and sleeves.

Key benefits of graphene nanotubes in rollers and sleeves

The incorporation of graphene nanotubes in the production of polyurethane rollers and sleeves brings several significant advantages:

- Homogeneous, permanent conductivity

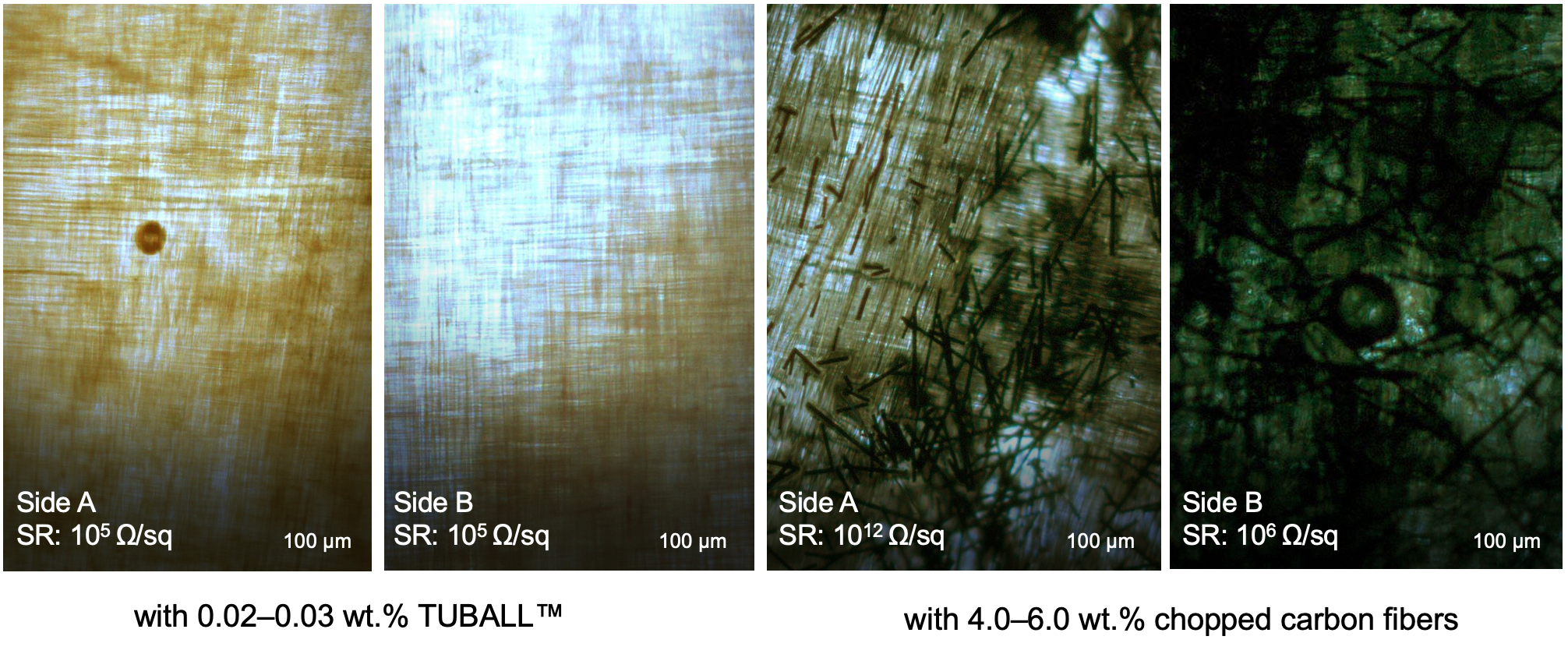

Unlike carbon black or chopped carbon fiber, graphene nanotubes achieve uniform distribution in materials, both at the surface and through its thickness and leave no black “smearing” traces on the surface of output products (fabric, paper, film, etc.), thus preventing the occurrence of rejects.

Picture 3. Composite layer made with fiber glass and thermoset resin, enriched with TUBALL (left) and chopped carbon fiber (right) for conductivity.

- Full range of electrical resistivity

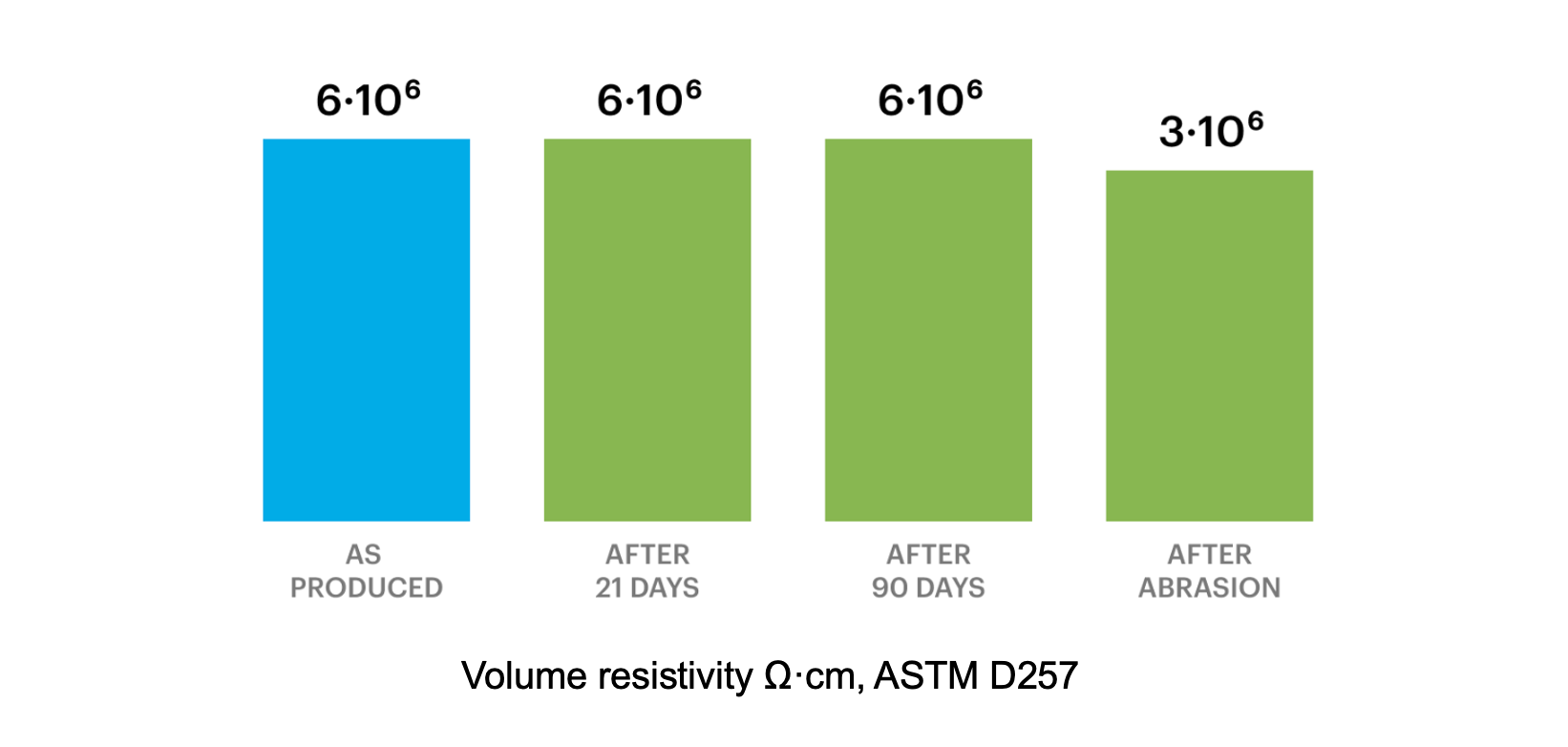

Graphene nanotubes provide a wider range of resistance levels as compared to ammonium salts. To obtain volume resistivity within the range of 109–104 Ω∙cm and independent from humidity and temperature, it is sufficient to add graphene nanotubes in a working concentration at a level of 0.02–0.03 wt.%, which is 100 times less than that of ammonium salts and 500 times less than that of carbon black.

Picture 4. Electrical conductivity of polyurethane products over time according to OCSiAl internal formulations.

- Improved casting stability and production cycle

Graphene nanotubes are chemically inert, meaning they do not negatively impact casting or curing processes. Even an ultralow loading of nanotubes makes it possible to provide PU products with stable conductivity while preserving color and original mechanical properties. As a result, Shore A hardness in the range of 45A–96A can be achieved in the material without compromising quality. This previously impossible to achieve set of properties results in an optimized production cycle of sleeves and improved stability of casting.

- Easy processing

Easy-to-use concentrates of pre-dispersed graphene nanotubes, produced by OCSiAl, make it possible to homogeneously distribute nanotubes in polyurethane systems with standard equipment. This new graphene nanotube technology gives manufacturers the opportunity to improve the performance of their standard products without making processing more complicated.

- Higher production quality

Substituting conventional conductive agents with ultralow dosages of graphene nanotubes not only makes it possible to meet conductivity targets but also enhances production quality and contributes to sustainability by reducing material volume and eliminating dust production.

Industrial cases of nanotube-modified polyurethane products

The ability of graphene nanotubes to provide polyurethane with electrical conductivity with minimal effect on material rheology, mechanical properties, or color boosts their application in various industries:

- Industrial polyurethane rollers

Industrial polyurethane rollers are a rugged, durable, tough, and strong type of caster capable of carrying up to five tons. These rollers are preferred in demanding industries like mining and packaging due to their ability to carry heavy loads. By incorporating just 0.2% TUBALLTM MATRIX 202, these rollers achieve a surface resistivity below 109 Ω/sq, ensuring anti-static properties crucial for applications in the mining and packaging industries.

- Polyurethane printing rollers

These rollers are used for printing on plastic, cardboard, and paper packagin. To achieve permanent, stable anti-static properties without “hot spots”, 17 wt.% conductive carbon black was replaced with 0.4 wt.% TUBALL™ MATRIX 200x-series. Using graphene nanotubes makes it possible to maintain the original mechanical properties of polyurethane and achieve a clean manufacturing process, free from carbon black powder or dust.

- Polyurethane printing sleeves for flexographic printing

To avoid paper sticking, which degrades print quality, slows down the printing process, increases operational costs, and—in rare cases when solvent-based ink is used without conducting rollers—can even result in explosions, TUBALL™ MATRIX 301 was introduced into the polyurethane or epoxy resin covering and TUBALL™ MATRIX 204 was introduced into the thermoset resin impregnated fiberglass layer. A stable surface resistivity below 106 Ω/sq, maintained mechanical properties, high hardness, and no deformation demonstrate the adaptability of graphene nanotubes in different systems.

- Polyurethane diagnostic disc and ball pigs for oil and gas applications

Pipeline inspection gauges (PIGs) ensure efficient removal of sludge from internal surfaces in oil and gas pipelines and of liquids from natural gas lines. To eliminate the risk of accident or explosion due to the high friction that occurs during ball pig or diagnostic discs moving through the pipe, graphene nanotubes were added to the originally insulative polyurethane. Achieving a volume resistivity below 109 Ω∙cm with 0.3% TUBALLTM MATRIX 202 enables anti-static properties in ball pigs, guaranteeing the safety of equipment and pipes. At the same time, nanotubes make it possible to maintain the mechanical properties of the polyurethane, which allows cleaning pigs to withstand harsh operation conditions.

The integration of graphene nanotubes in polyurethane rollers and sleeves presents a transformative solution, providing enhanced electrical conductivity, improved mechanical properties, and production efficiency. The application scope becomes wider, and other industrially approved cases of nanotube-modified polyurethane include anti-static PU-based leather for hospital bed coverings, ESD-protective touchscreen gloves, artificial water-based PU leather car seats with anti-dust effect due to anti-static properties, self-leveling or concrete floors, etc. The versatility of graphene nanotubes, coupled with their ability to overcome the limitations of traditional additives, positions them as a cornerstone in the future of advanced material engineering.

- ASTM D412: Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension (https://www.astm.org/d0412-16r21.html); ASTM D2240 Standard Test Method for Rubber Property - Durometer Hardness (https://www.astm.org/d2240-15r21.html), ISO 37: Rubber, vulcanized, or thermoplastic — Determination of tensile stress-strain properties(https://www.iso.org/standard/68116.html) and others.

- IQS Directory (https://www.iqsdirectory.com/articles/rubber-rollers/polyurethane-rollers.html)