Graphene nanotubes for polyurethane cast systems and coatings: permanent electrical conductivity with preserved mechanical properties

TUBALL™ graphene nanotubes, also known as single wall carbon nanotubes, provide permanent electrical conductivity to polyurethanes while preserving mechanical properties.

TUBALL™ graphene nanotubes are applied via easy-to-use anti-static masterbatches:

- TUBALL™ MATRIX concentrates based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes

- TUBALL™-based suspensions: TUBALL™ COAT_E, TUBALL™ LATEX

Choose the TUBALL™ product based on the carrier medium that suits your formulation:

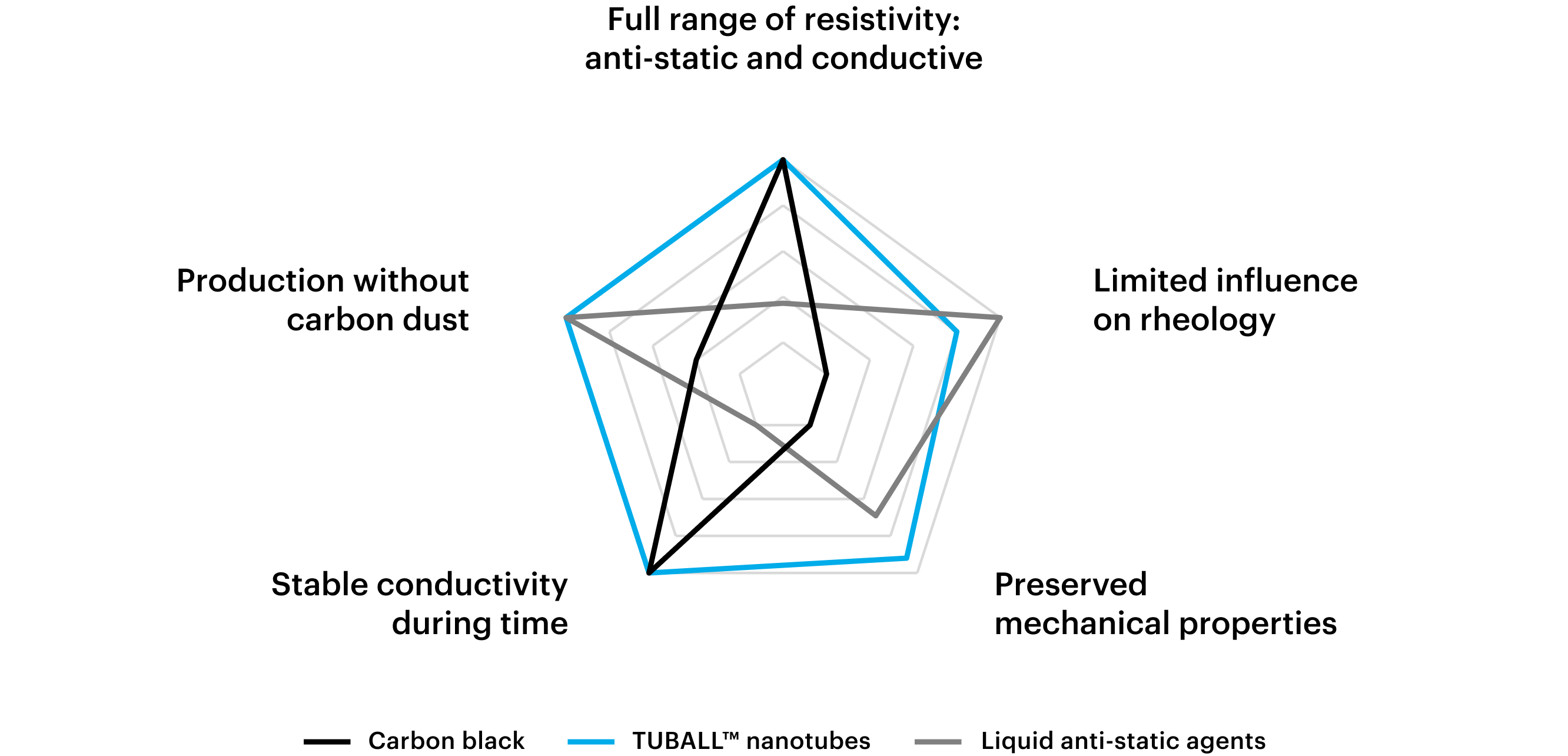

Increased performance of anti-static and conductive polyurethane products

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

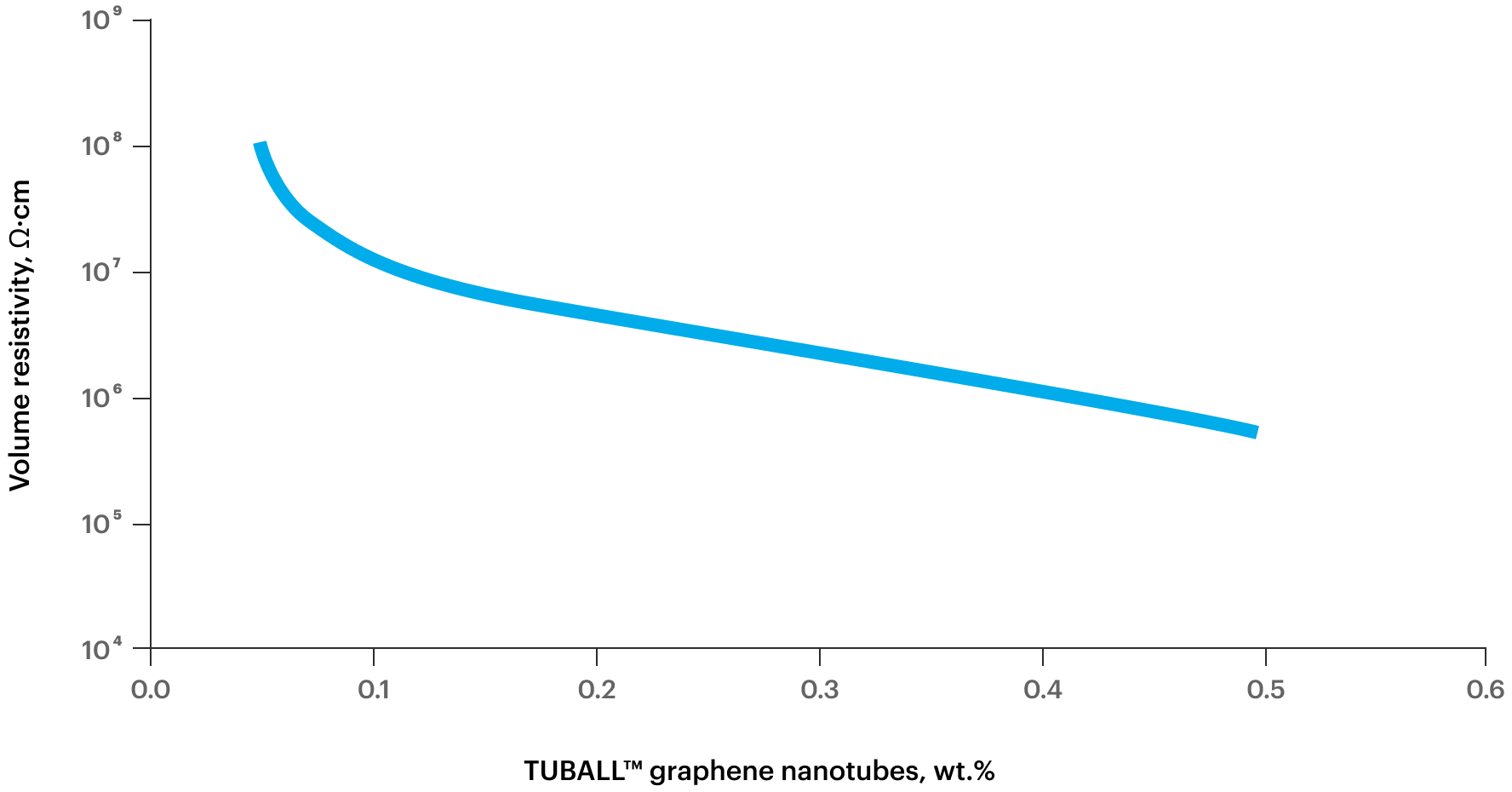

Full range of electrical resistivity

OCSiAl internal PU formulation. ASTM D257.

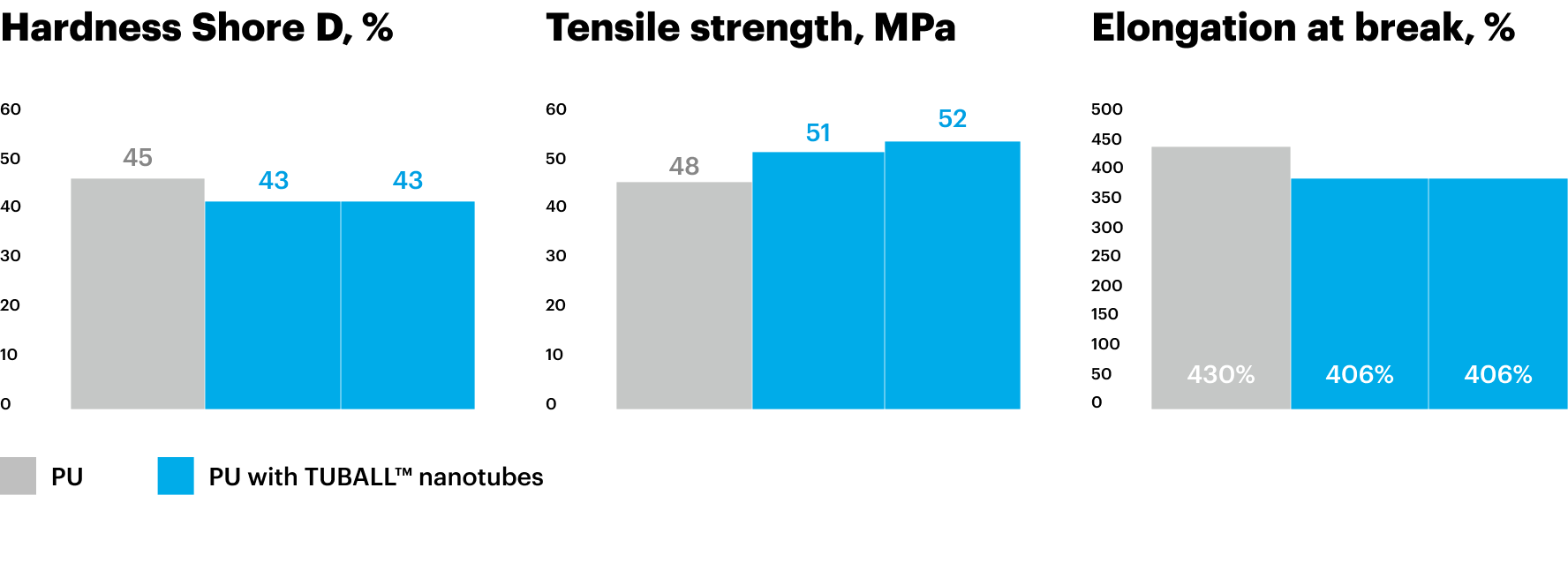

Preserved mechanical properties

Hardness: ASTM D2240 Shore D; Elongation: ASTM D412; Tensile strength: ASTM D412. TUBALL™ was introduced via TUBALL™ MATRIX 202.

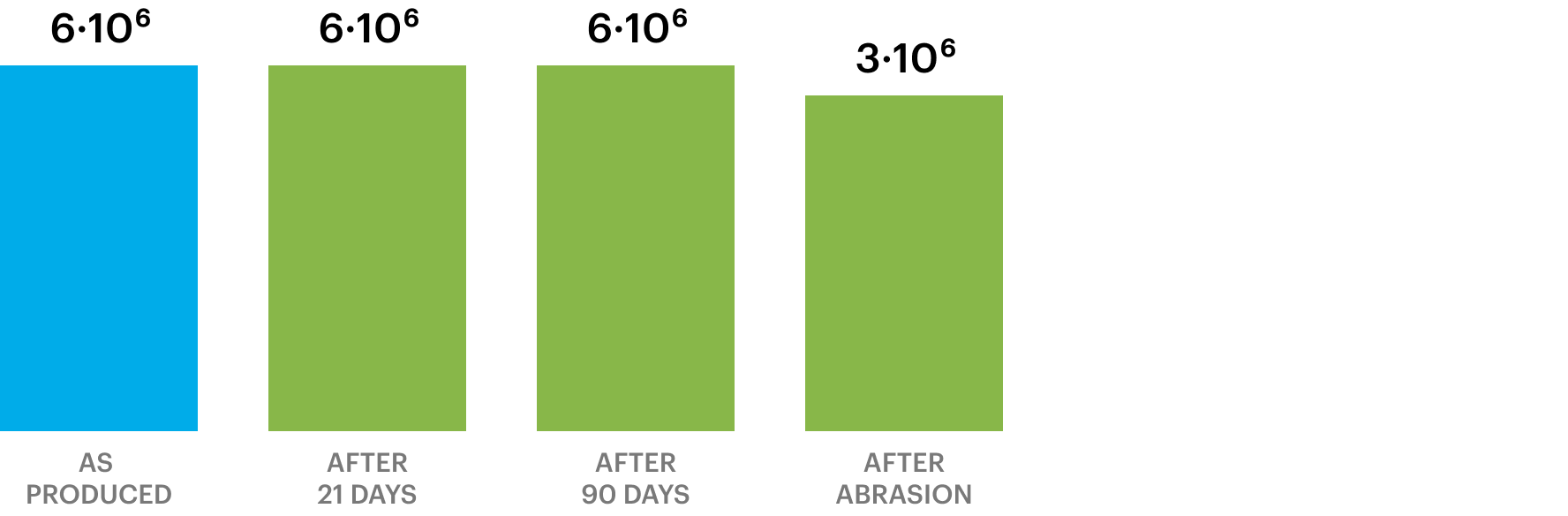

Permanent and stable volume resistivity

Volume resistivity Ω·cm, ASTM D257

Other benefits provided by TUBALL™ nanotubes for thermoset polyurethanes:

- Low dosage gives greater flexibility in the final formulation

- Easy to apply and the low dosage makes the logistics less complex and more efficient

- Wide range of colors for various conductive PU coating and textile applications

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™-based products.

For solvent-free polyurethane (PU) systems

For solvent-based polyurethane (PU) systems

Application cases

Industrial Castors

Mining Rollers

Printing Roller

Pay close attention to the processing guidelines for TUBALL™ MATRIX

Download PDF version:

Or watch the processing guidelines video:

TUBALL™ MATRIX - Processing guidelines

Additional information

Anti-static Polyurethane: Overview of the production and the product niche with an OCSiAl expert

Add anti-static to polyurethane: industrial case with graphene nanotubes

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample.