Graphene nanotubes for anti-static latex: ESD safety gloves that can be used with touchscreens

TUBALL™ nanotubes are a unique anti-static agent that provides electrical conductivity at low dosages not achievable with any standard conductive additive. These low dosages enable reductions in the electrical resistivity of the material with minimal impact on mechanical properties, processing and color.

OCSiAl supplies a ready-to-use water-based dispersion with properly dispersed and stabilized TUBALL™ graphene nanotubes. This product contains a user-friendly stabilizer and can be used for all kinds of water-based latexes, such as nitrile, natural and polyurethane.

TUBALL™ graphene nanotubes: Good performance on all key parameters

In contrast to other conductive agents, TUBALL™ graphene nanotubes are versatile conductive agents offering good performance on all key parameters.

|

Parameter |

Inorganic salts* |

Carbon black-based dispersion (dry content) |

MWCNT dispersion |

TUBALL™ LATEX dispersion |

|

Working dosage |

less than 1 wt.% |

5–10 wt.% |

2–3 wt.% |

0.06–0.1 wt.% |

|

Resistance requirements |

108 Ω |

|||

|

Resistance achieved (volume resistivity), Ω |

none |

107–109 |

107–109 |

107–108 |

|

Resistance achieved (surface resistivity), Ω |

>109 |

107–109 |

106–109 |

106–108 |

|

Black dots on the surface |

none |

yes |

yes |

none |

|

Available color range |

wide |

none |

none |

wide |

|

Minimum film thickness required |

50 µ |

150–200 µ |

150–200 µ |

any |

|

Influence on mechanical performance |

none |

strong negative |

strong negative |

none |

|

Resistance is independent of humidity |

no |

yes |

yes |

yes |

|

‘Hot spots’ |

possible |

yes |

possible |

none |

|

Stable resistance over time |

no |

medium |

medium |

yes |

|

Significant changes are required in the production process |

none |

yes |

yes |

none |

|

Cost of anti-static property |

low |

comparable |

comparable |

comparable |

* Inorganic salts were used in more than 80% of gloves until 2014. Since the new EN 16350:2014 standard for safety wear was launched with requirements for volume resistivity, these salts can no longer be used for ESD gloves production.

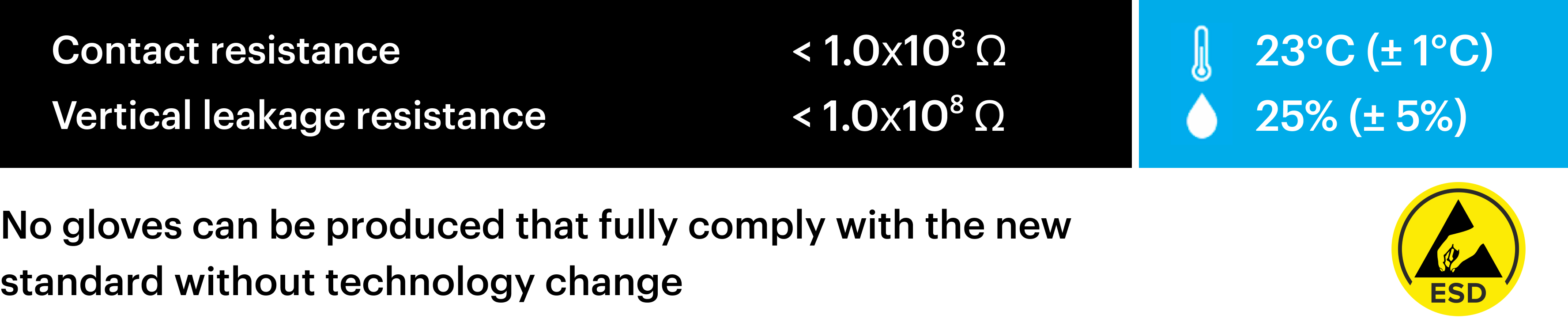

Key benefit 1: Compliance with the EN 16350:2014 standard

New safety regulations related to electrostatic protection are being developed to keep pace with the increasing automation of industrial facilities.

The introduction in July 2015 of the EN 16350:2014 standard, which deals with the electrostatic characteristics of protective gloves, meant that manufacturers had to look for new ways to comply with the updated requirements.

TUBALL™ LATEX makes it possible to achieve permanent and humidity-independent conductivity in full compliance with the new European standard EN 16350:2014

The new standard for ESD GLOVES. EN 16350:2014

Key benefit 2: Touchscreen operation of industrial gloves

TUBALL™ graphene nanotubes provide an anti-static effect that allows smooth operation of touchscreens without the gloves having to be removed and that ensures worker and product protection.

Graphene nanotubes allow these gloves to use standard liners without conductive yarns and to keep the same dipping process and formulation.

Key benefit 3: Colored anti-static compounds

TUBALL™ graphene nanotubes allow the required anti-static performance to be achieved in all water-based latex systems. The effective dosage required varies depending on the formulation of the compound and on the thickness and type of glove.

ESD gloves with TUBALL™. Natural & nitrile latexes

*Glove made by an industrial partner with 0.05 wt.% of TUBALL™

The extremely low dosage required of graphene nanotubes creates the opportunity to produce colorful solutions where desired.

Colored anti-static nitrile film with 0.06 wt.% of TUBALL™

Surface resistivity of 107 Ω

Key benefit 4: Standard processing and mixing equipment

Water-based suspensions with high-quality dispersions of graphene nanotubes and latex-friendly chemicals provide compatibility with standard processes and equipment.

The dispersion can be added during the latex compounding stage and does not affect the manufacturing process.

Please pay close attention to usage guidelines for TUBALL™ LATEX H2O for the production of anti-static natural/synthetic latex compounds.

Other benefits

- An effective concentration of 0.05 wt.% of TUBALL™

- Electrical resistance of < 106 Ω

- Maintained mechanical properties

- Suspensions available for all latex types

- Material is ready to use “as produced”

Contact us to discuss your project specifications or to request a TUBALL™ LATEX sample

Related product

Application cases

Cleanroom Latex Glove

Latex Textile Coating

ESD protective touchscreen gloves

Please pay close attention to usage guidelines for TUBALL™ LATEX H2O for production of anti-static natural/synthetic latex compounds

Or watch video instruction:

TUBALL™ LATEX - Processing Guidelines

How can you avoid carbon dust at compounding plants?

Additional resources:

ESD Colored Latex Gloves - New Standard

Complying with the new standard for electrostatic properties in protective gloves

Contact us to discuss your project specifications or to request a TUBALL™ LATEX sample