Graphene nanotubes for automotive primers: conductivity, cost benefits and preserved light colors

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of additives based on polymer-carriers and pre-dispersed TUBALL™ graphene nanotubes.

Choose the TUBALL™ MATRIX product based on the carrier medium that suits your formulation:

|

Target system |

Solvent-based acrylic systems |

Water-based acrylic systems |

|

Additive carrier |

Plasticizer + stabilizing agent |

Surfactant + stabilizing agent |

|

Triethylene glycol dimethacrylate + ammonium salt of polyolefin-based derivatives |

Alkylene glycol derivative + distyryl biphenyl derivative |

|

|

Product |

|

|

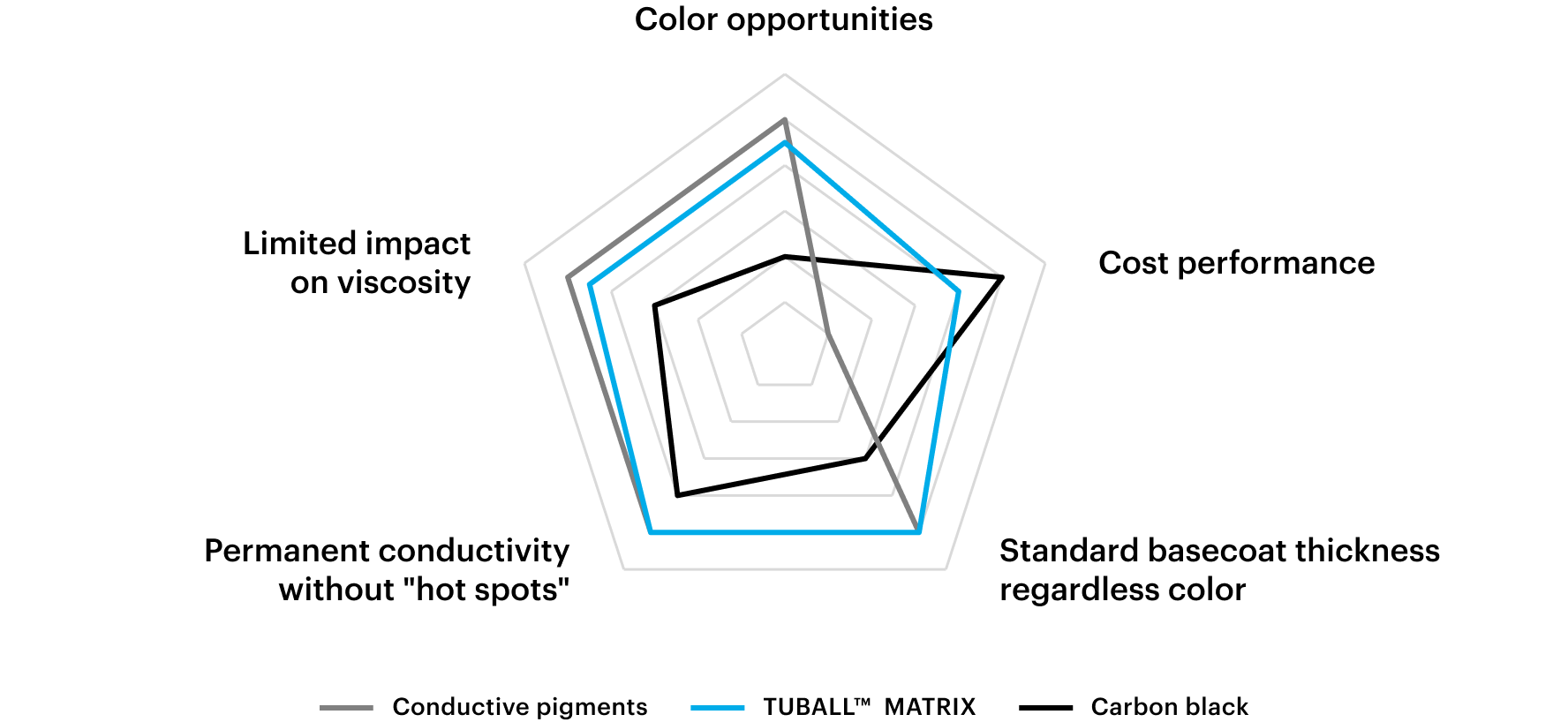

TUBALL™ graphene nanotubes are a versatile conductive agent offering strong performance on all key parameters

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

Сolor opportunities

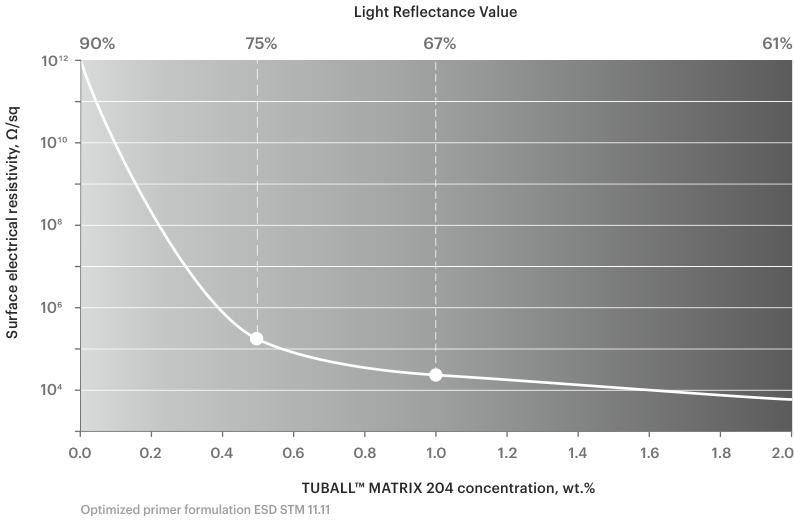

TUBALL™ nanotubes, applied at low dosages, allow the production of colorful and even light gray primers with an L-value as high as 75%.

Cost performance

In contrast to other conductive additives used for light-colored primers (e.g. conductive TiO2 or mica), TUBALL™ nanotubes can be applied at low dosages, providing cost efficiency.

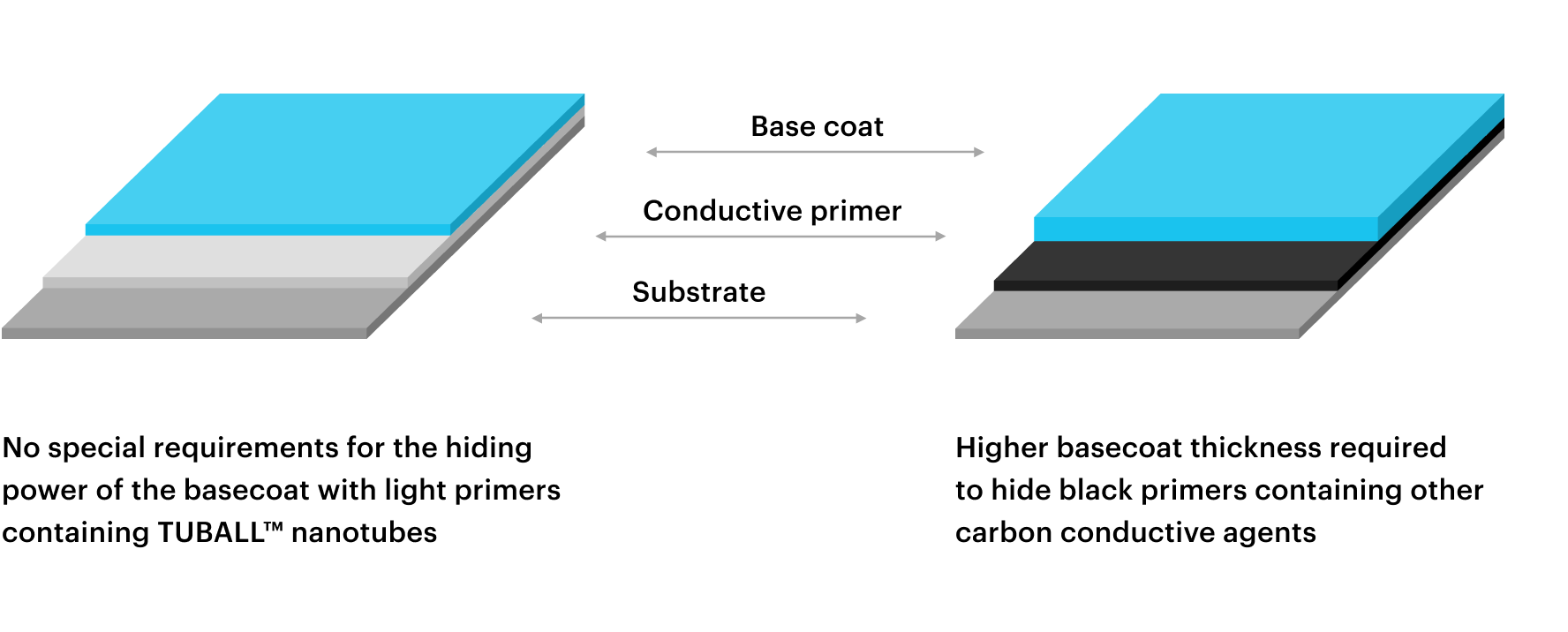

Standard basecoat thickness regardless of color

The light colors of primers containing TUBALL™ nanotubes provide the opportunity to apply a thinner basecoat in comparison with primers containing other carbon conductive agents.

Standard processing

TUBALL™ MATRIX can be applied with widely used equipment.

Other benefits provided by TUBALL™ nanotubes for conductive primers:

- Clean production without carbon dust

- Low dosage gives greater flexibility in the final formulation

- Easy to apply and the low dosage makes the logistics less complex and more efficient.

TUBALL™ MATRIX for solvent-based acrylic formulations

TUBALL™ MATRIX for water-based acrylic formulations

Application cases

Conductive Solvent-based Acrylic Primer

Conductive Waterborne Acrylic Primer

Electrically heated coating

Download application case in PDF format:

Please pay close attention to the processing guidelines for TUBALL™

Download PDF version:

Additional information

Conductive Automotive Primers - New solution for all market segments without cost penalty

Conductive automotive primers with TUBALL™ MATRIX - Processing guide

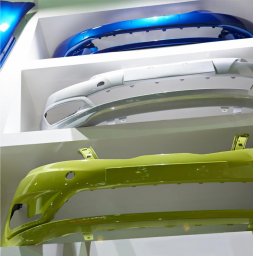

TUBALL™ graphene nanotubes, also known as single wall carbon nanotubes, can be used in the production of solvent-based and water-based conductive primers to be applied to plastic parts for electrostatic painting.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample.