Anti-static additive for conductive acrylic resin with maintained durability and color

TUBALL™ graphene nanotubes are the ultimate anti-static agent to achieve the required conductivity level in acrylic systems without sacrificing the color of the final product or its durability.

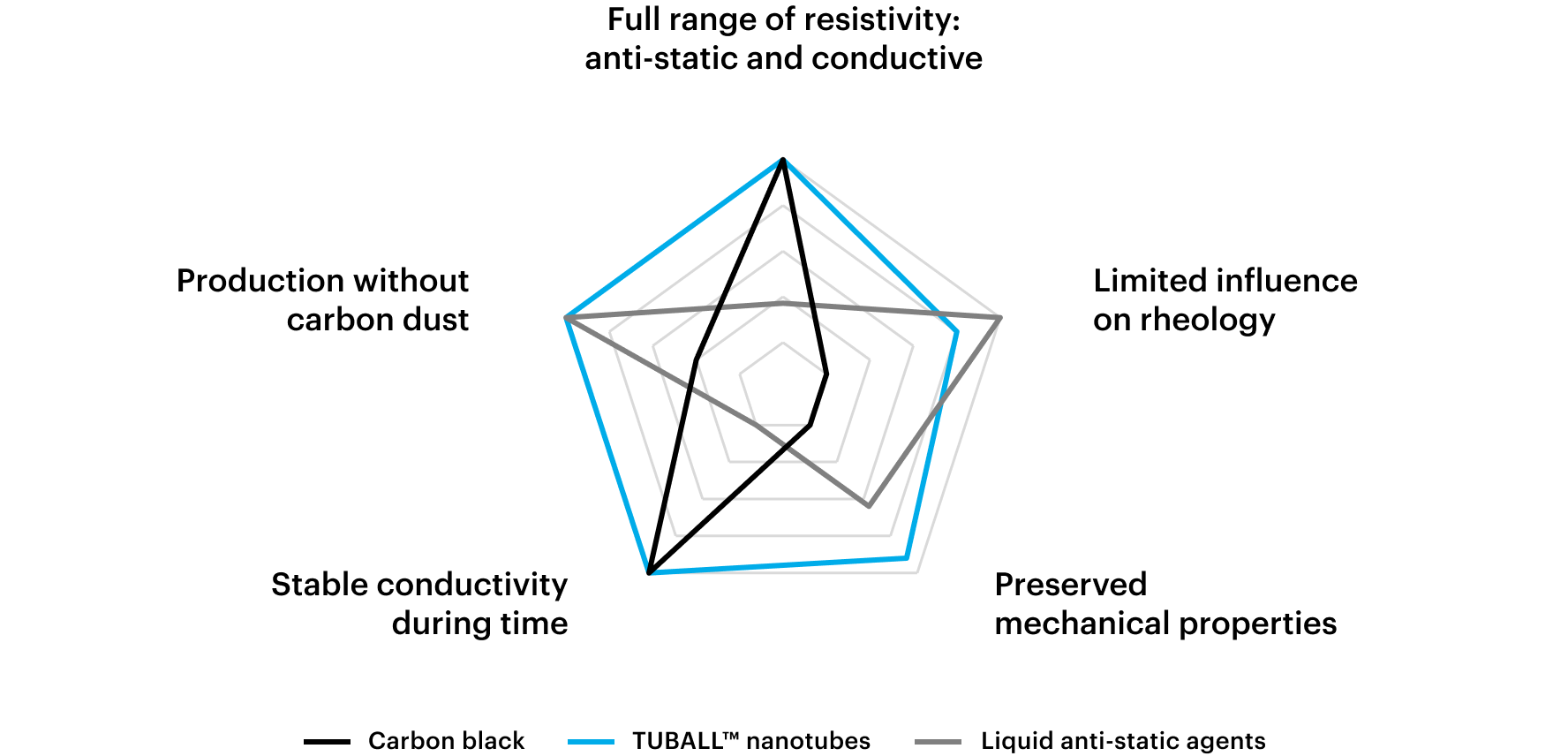

ANTI-STATIC AGENTS: TRADITIONAL VS TUBALL™

Note. This diagram provides average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

The unique properties of graphene nanotubes (single wall carbon nanotubes) enable them to create a uniform conductive, reinforced network inside thermoset materials resulting in a combination of permanent and stable anti-static properties that is impossible to achieve using ammonium salts. An ultra-low working loading of nanotube-formulated conductive filler, in contrast to carbon black, unlocks a much wider color palette for ESD acrylic systems and helps to avoid negative impacts on mechanical performance, allowing for prolonged service life.

TUBALL™ MATRIX meets key technical requirements

| Parameter | Liquid anti-static agents | Carbon black | |

|---|---|---|---|

| Working dosage, wt.% | 0.2–4 | 4–12 | 0.1–0.5 |

| Resistivity range, Ω/sq | 108–1011 | 105–1011 | 104–1011 |

Influence on mechanical performance |

small negative | strong negative | none |

| Influence on rheology | none | strong negative | acceptable |

| Color opportunity | possible | none | possible |

| Application via spray technology | possible | challenging | possible |

| Dust formation during production | none | high | none |

| Resistivity independent of humidity | no | yes | yes |

| Stable resistivity over time | no | yes | yes |

Results for optimized formulation based on OCSiAl data.

Graphene nanotubes in conductive acrylic systems guarantee:

- The full range of conductivity with minimal working dosages

- Uniform, permanent conductivity during the whole service life

- The same vivid colors as nonconductive systems

- Prolonged durability of the end product

- Clean production process with standard equipment and original formulation

To simplify the handling of graphene nanotubes and adapt your manufacturing without adding equipment or changing formulation, OCSiAl has developed a line of industry-friendly solutions in the form of TUBALL™ MATRIX paste concentrates and liquid suspensions for acrylic systems. This anti-static masterbatch grants enhanced ESD charge protection, which is essential in various industrial protective conductive coatings, construction paints, automotive primers, various inks, films, adhesives, and ESD packaging.

Depending on the local government regulations on the carrier, type of resin, solvent content, layer thickness, filler dosage, and some other key parameters, specific TUBALL™-based solutions should be applied.

To get more details on products, please click the product cards below, or contact us for assistance in choosing the right ESD additive.

Related products

Related videos

How can you achieve energy-efficient and low-carbon thermal comfort for streets and buildings?

Conductive Automotive Primers: New solution for all market segments without cost penalty

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample