Conductive additive for glass fiber filled polyamide compounds with maintained mechanical properties and required processability

TUBALL™ graphene nanotubes in the form of TUBALL™ MATRIX 808 is a versatile conductive additive based on polyol ester carrier. It has been specifically designed to provide superior electrical conductivity to thermoplastic materials, while retaining mechanical properties and keeping the MFI level of the glass fiber filled compound.

In contrast to conventional additives, TUBALL™ graphene nanotubes used at an ultralow working dosage bring additional value by preserving good impact strength and a high MFI level that makes it possible to produce complex injection molded parts. This is particularly hard to achieve in fiberglass-filled compounds using multi wall carbon nanotubes or carbon black.

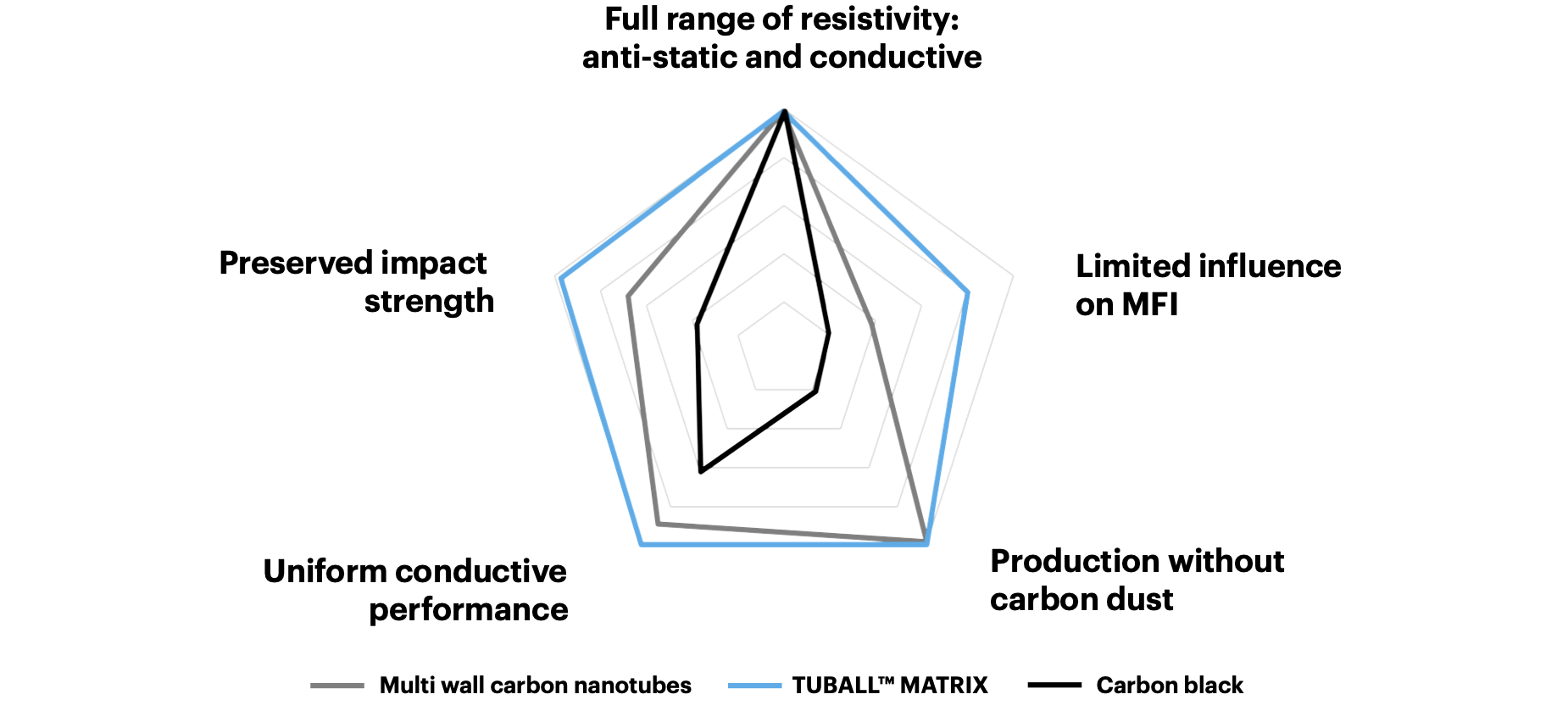

CONDUCTIVE ADDITIVES FOR GLASS FIBER FILLED PA: TRADITIONAL VS TUBALL™

Note. This diagram is based on an average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

Benefits provided by TUBALL™ nanotubes for GF-filled PA:

- Ultra-low dosage starting from just 0.05 wt.% TUBALL™ graphene nanotubes*

- Maintains good balance of mechanical properties

- Enables a new combination of GF-filled PA properties in comparison to standard conductive agents

- Permanent, stable and uniform electrical resistivity without “hot spots”

- Stable performance reducing the number of out-of-spec parts

- Good processability and easy handling

- Allows production of conductive parts that retain colors

*Dosages may vary depending on the formulation, processing, and products.

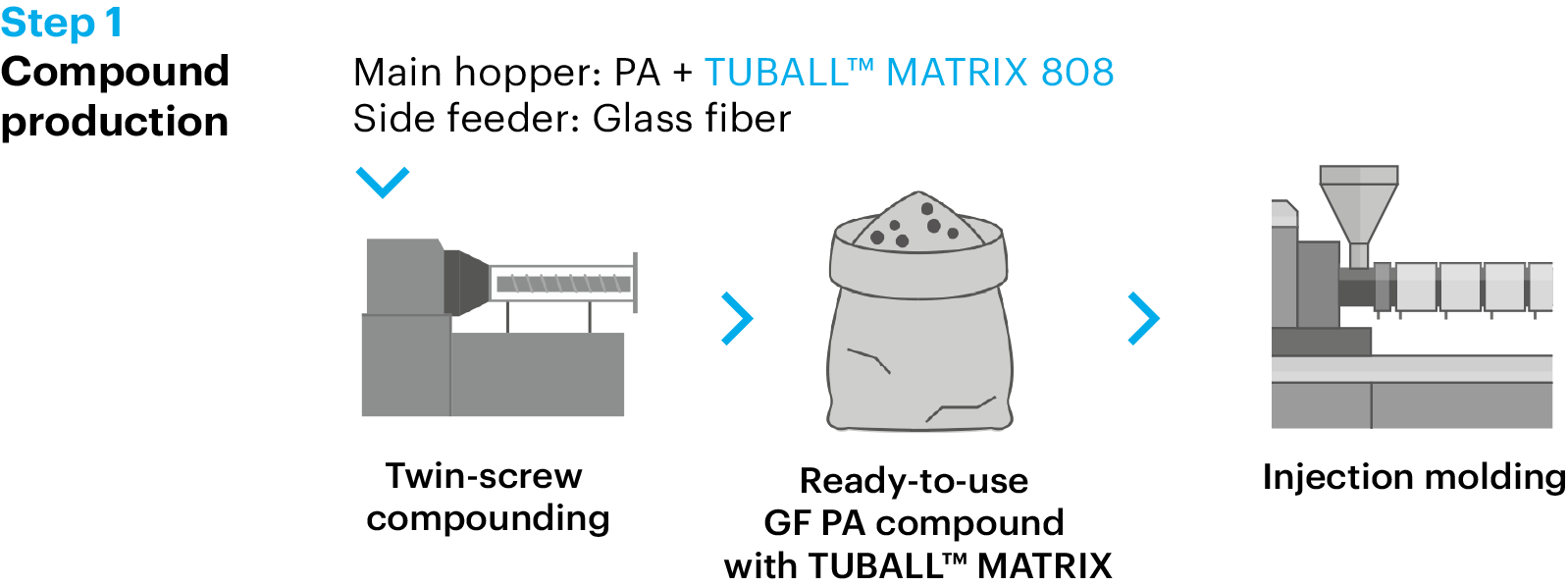

EASY TO APPLY WITH STANDARD EQUIPMENT

TUBALL™ MATRIX can be processed with standard equipment widely used in the thermoplastics industry.

PA enhanced with TUBALL™ graphene nanotubes has found wide usage in the automotive e-painting, automotive safety, ESD materials and ATEX applications.

Additional information

How to grant conductivity to glass fiber reinforced polyamide: compounding guide

3 methods of quality control for conductive thermoplastics with graphene nanotubes

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample