Electrically conductive additive for thermoplastics with retained mechanical performance and required processability

TUBALL™ graphene nanotubes (also known as single wall carbon nanotubes) demonstrate promising results as conductive additives for plastics.

Graphene nanotubes create a dense conductive network inside thermoplastic compounds that guarantees stable electrical conduction performance with no adverse effects on the mechanical and rheological properties of plastics.

OCSiAl markets nanotube-based concentrates for wide range of thermoplastics: glass fiber filled polyamide, polyamide, glass fiber filled PPS, PVC-plastisol, TPU, polycarbonate, ABS, and PC-ABS polypropylene. Other conductive additives with nanotubes for polyethylene, polystyrene, and others are undergoing validation and are referred to as beta products.

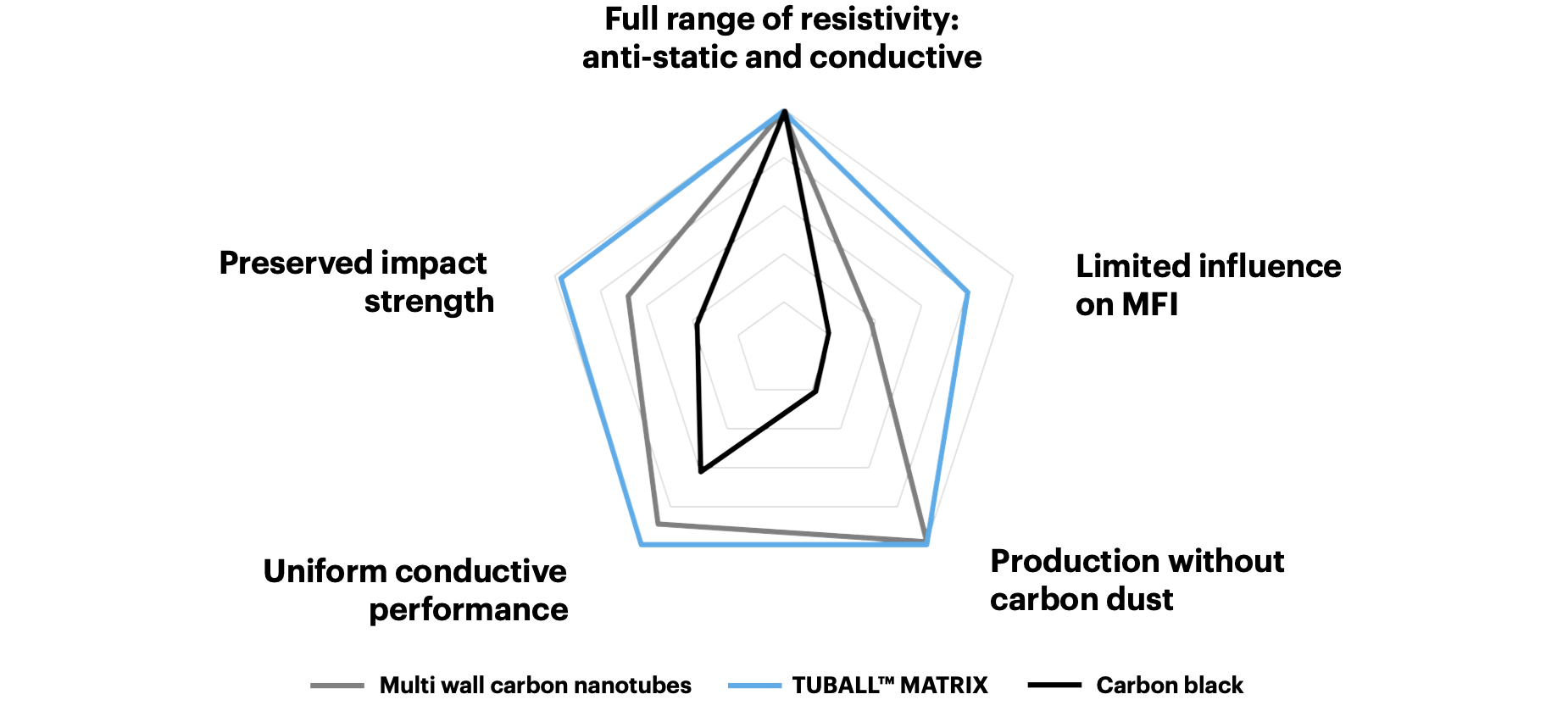

CONDUCTIVE ADDITIVES: TRADITIONAL VS TUBALL™

Note: This diagram provides average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

TUBALL™ MATRIX: multiple benefits

- Enables a new combination of properties in comparison to standard conductive additives

- Surface resistivity of 103–109 Ω/sq*

- Volume resistivity of 103–109 Ω∙cm*

- Maintains a good balance of mechanical properties

- Stable performance reducing the number of out-of-spec parts

- Good processability

- Permanent homogeneous resistivity without “hot spots”

- High surface quality

- Allows production of conductive parts that retain colors

- Freedom to incorporate other functional ingredients

*Values may vary depending on the formulation, processing, and products. The values shown are given as the typical reference.

TUBALL™ graphene nanotube solutions for plastics

To adapt nanotubes to a standard manufacturing process without purchasing specific equipment or changing the original formulation, OCSiAl has developed the TUBALL™ MATRIX line of concentrates.

Related videos

Anti-static properties in rotomolding: Easy cost-effective solution for the whole conductivity range

Electrical conductivity for PVC plastisol

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample