Anti-static additive for conductive polyester with maintained durability and color

TUBALL™ graphene nanotubes are a universal conductive agent that outperforms its analogs, such as carbon black, carbon fiber, mica, or other conductive polymers, in the stability of conductive properties and the wide color palette it unlocks for end products.

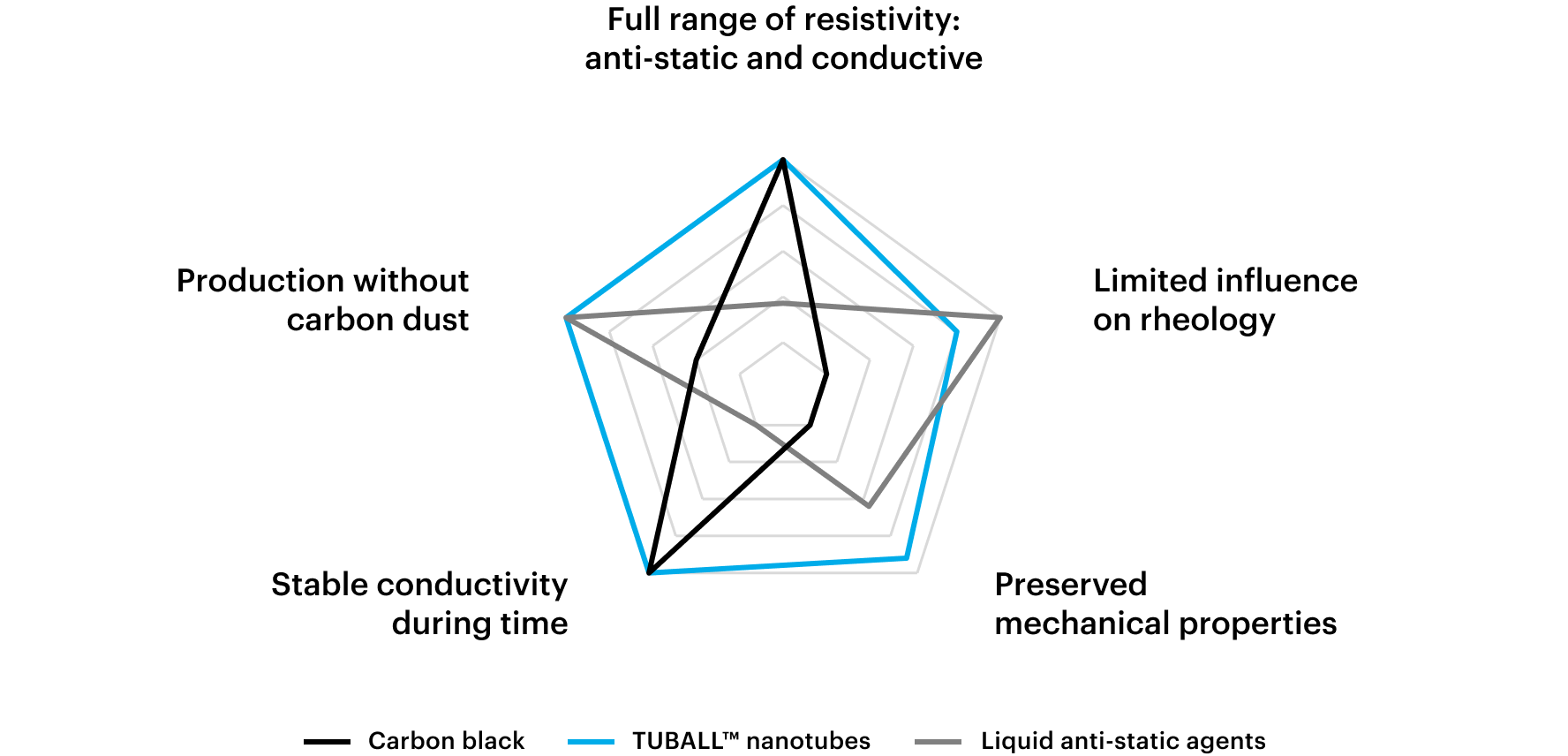

Anti-static agents: traditional vs TUBALL™

Note. This diagram provides average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

For simple adoption of nanotubes in a standard manufacturing process with original equipment and formulation, OCSiAl has developed a line of user-friendly TUBALL™ MATRIX concentrates. The effective loading of this conductive filler in the overall polyester compound is about 0.5%, which is a dozen times lower than that of carbon black.

TUBALL™ MATRIX anti-static masterbatch in polyester systems enables:

- Permanent, stable conductivity without "hot spots"

- Flexibility in coloring of the final product

- Simple handling without the powder or dust associated with other carbon nanomaterials

- Possibility to apply via spraying techniques thanks to no viscosity increase

TUBALL™ MATRIX meets key technical requirements

| Parameter | Ammonium compounds | Carbon black | TUBALL™ MATRIX |

|---|---|---|---|

| Working dosage, wt.% | 0.2–4 | 4–12 | 0.1–0.5 |

| Resistivity range, Ω/sq | 108–1011 | 105–1011 | 104–1011 |

Influence on mechanical performance |

small negative | strong negative | none |

| Influence on rheology | none | strong negative | acceptable |

| Color opportunity | possible | none | possible |

| Application via spray technology | possible | challenging | possible |

| Dust formation during production | none | high | none |

| Resistivity independent of humidity | no | yes | yes |

| Stable resistivity over time | no | yes | yes |

Results for optimized formulation based on OCSiAl data.

To know more about nanotube products, please click on the product cards below or contact us.

Related videos

How can you achieve energy-efficient and low-carbon thermal comfort for streets and buildings?

Anti-static filament winding products: New generation technology

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample