Anti-static agent for electrically conductive thermoset resins with maintained mechanical performance and color

TUBALL™ graphene nanotubes (also known as single wall carbon nanotubes) are the most effective anti-static agent. This conductive filler avoids drawbacks in other key parameters, giving thermoset compound manufacturers, engineers and installers the ability to produce highly competitive composites and coatings with a totally new set of properties.

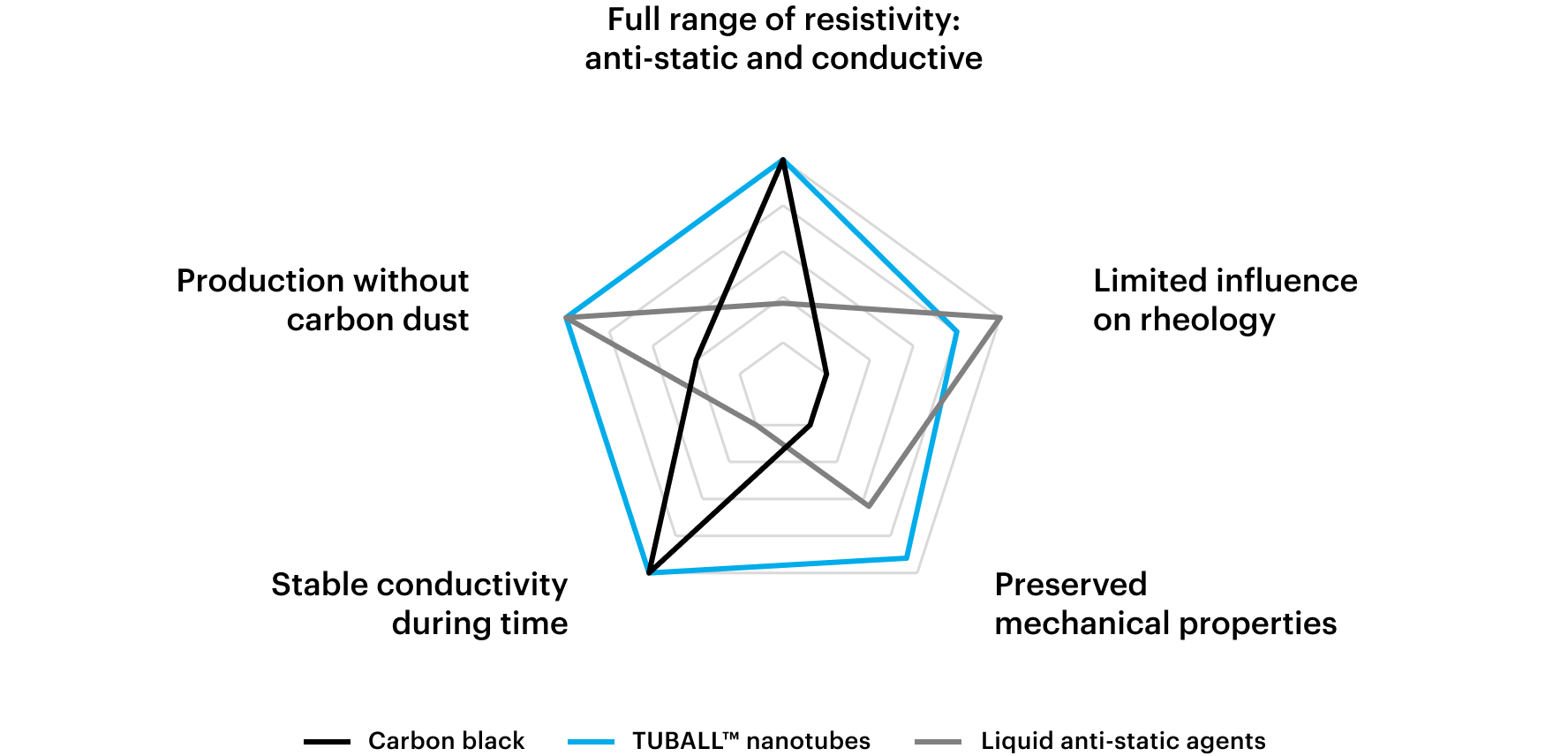

Anti-static agents: traditional vs TUBALL™

Note. This diagram provides average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

In comparison to conventional ESD additives used for various conductive thermoset resins, such as carbon black, carbon fibers or ammonium salts, TUBALL™ graphene nanotubes deliver the level of conductivity while at the same time preserving the original color of the thermoset compound and maintaining or even improving beneficial mechanical properties.

Color change, RAL

Graphene nanotube technologies are widely applied in most industries, including the automotive, construction, alternative energy, petrochemical, healthcare, pharmaceutical, electronics, and marine transportation sectors, as well as in cleanrooms and sports equipment.

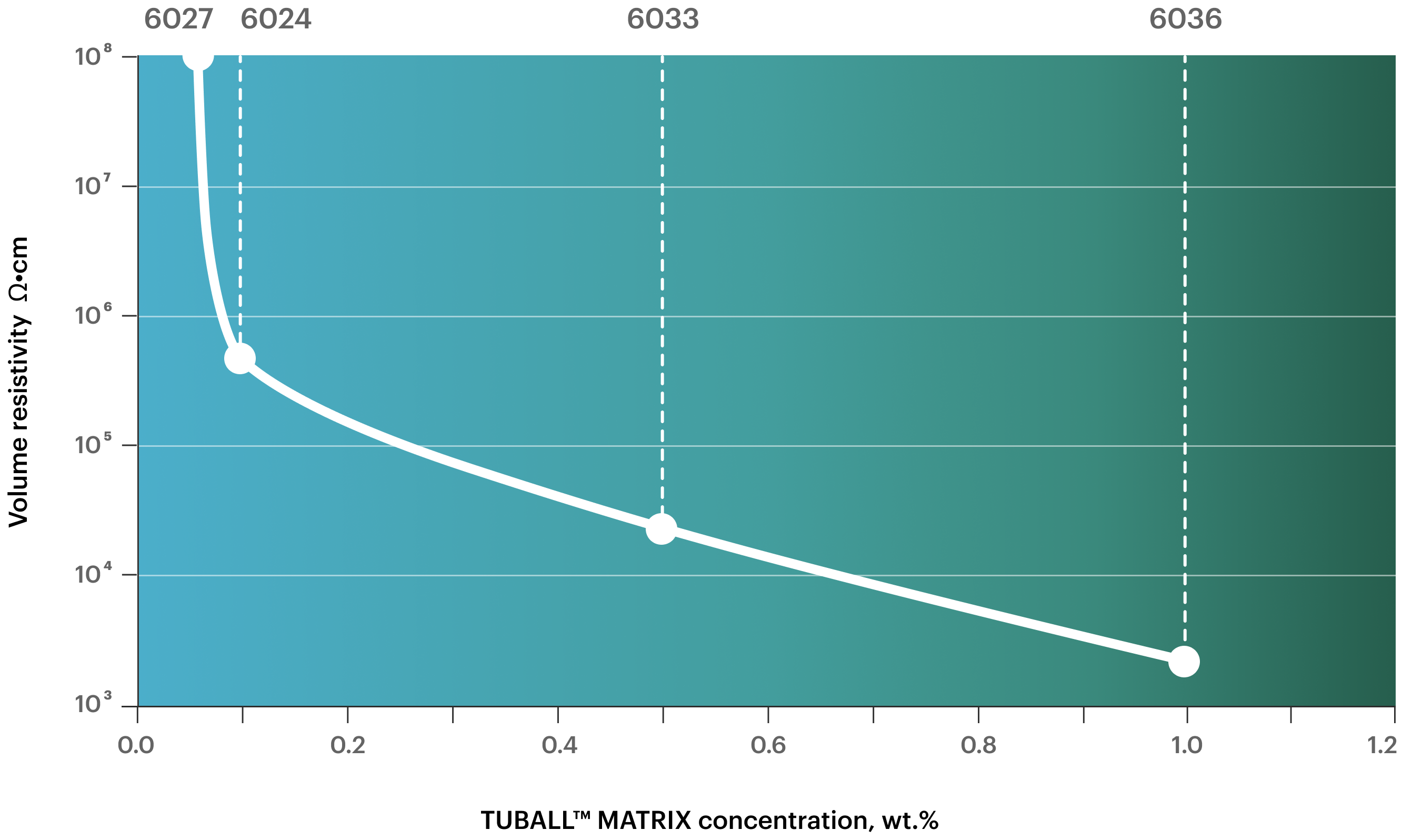

To adapt nanotubes to a standard manufacturing process without purchasing specific equipment or changing the original formulation, OCSiAl has developed TUBALL™ MATRIX line of concentrates. TUBALL™ MATRIX concentrates are compatible with the most commonly used technologies for the production of fiber-reinforced composites, including hand layup, filament winding, pultrusion, SMC/BMC, and spray-up.

TUBALL™ MATRIX meets key technical requirements

| Parameter | Ammonium compounds | Carbon black | TUBALL™ MATRIX |

|---|---|---|---|

| Working dosage, wt.% | 0.2–4 | 4–12 | 0.1–0.5 |

| Resistivity range, Ω/sq | 108–1011 | 105–1011 | 104–1011 |

Influence on mechanical performance |

small negative | strong negative | none |

| Influence on rheology | none | strong negative | acceptable |

| Color opportunity | possible | none | possible |

| Application via spray technology | possible | challenging | possible |

| Dust formation during production | none | high | none |

| Resistivity independent of humidity | no | yes | yes |

| Stable resistivity over time | no | yes | yes |

Results for optimized formulation based on OCSiAl data.

Applying only 0.1 wt.% of TUBALL™ MATRIX in thermoset compounds leads to:

- Uniform, permanent conductivity throughout the whole service life

- Preserved original color of compound

- Maintained or even enhanced durability of the material

- Highly competitive product without additional investments

TUBALL™ MATRIX anti-static masterbatches are available for all industry-standard thermoset systems, including acrylic, melamine, epoxy, phenolic, polyester, polyurethane and vinyl-ester.

TUBALL™ for thermosets

| Product | Carrier | Composition | Target systems | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solvent-free | Solvent-based | Water-based | |||||||||||||||

| Epo | Poly | Vinyl-ester | Poly | Epo | Poly | Vinyl-ester | Poly | Melamine | Phen | Acry | Epo | Poly | Acry | Phen | |||

| TUBALL™ MATRIX concentrates (Black flakes paste @ standard dosage 0.1%–1.0%) | |||||||||||||||||

| Plasticizer | Fatty acid glycidyl ester (2,3-epoxypropyl neodecanoate, CAS-No. 26761-45-5) | |||||||||||||||

| Plasticizer | Fatty carboxylic acid ester derivatives | |||||||||||||||

| Plasticizer + stabilizing agent | Fatty acid glycidyl ester (2,3-epoxypropyl neodecanoate, CAS-No. 26761-45-5) + (polymer + ammonium salt of polyolefins-based derivative (CAS-No. 398475-96-2)) | |||||||||||||||

| Plasticizer + stabilizing agent | Triethylene glycol dimethacrylate (CAS-No. 109-16-0) + ammonium salt of polyolefins-based derivative (CAS-No. 398475-96-2) | |||||||||||||||

| Plasticizer | Alkyl glycidyl ether (Oxirane, mono[(C12-14-alkyloxy) methyl] derivative, CAS-No. 68609-97-2) + ammonium salt of polyolefins-based derivatives (CAS-No. 398475-96-2) | |||||||||||||||

| Plasticizer + stabilizing agent | Alkyl glycidyl ether (Oxirane, mono[(C12-14-alkyloxy)methyl] derivative, CAS No. 68609-97-2) + ammonium salt of polyolefins-based derivatives | |||||||||||||||

| Plasticizer | Fatty carboxylic acid ester derivatives | |||||||||||||||

| Surfactant | Ethoxylated alcohol (C12-15-branched and linear, ethoxylated propoxylated, CAS No. 120313-48-6) | |||||||||||||||

| Surfactant + stabilizing agent | Alkylene glycol derivative + stabilizing agent ((disodium 2,2'-([1,1'biphenyl]-4,4’diyldivinylene) bis(benzenesulphonate, CAS No. 27344-41-8)) | |||||||||||||||

| TUBALL™ suspensions COAT_E (Black liquid @ standard dosage 1.5%–6.4%) | |||||||||||||||||

| Water + distyryl- biphenyl-derivative | Water + distyrylbiphenyl-derivative (CAS No. 27344-41-8) | |||||||||||||||

| Water + anionic surfactant | Water + anionic surfactant (sodium dodecylbenzenesulfonate (CAS No. 25155-30-0) | |||||||||||||||

Related products

Related videos

TUBALL™ for thermosets: new area of development and results from 2019 (Vladimir Kravchenko, OCSiAl

Application of graphene nanotubes in composite materials (Jim Lin, Zhongshan A&E Machinery Industry)

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample