Anti-static additive for conductive vinyl ester with maintained durability and color

TUBALL™ graphene nanotubes graphene nanotubes (also known as single wall carbon nanotubes) are used as a conductive filler to provide anti-static properties to vinyl-ester systems. They outperform widely used carbon black in their ability to preserve or even enhance mechanical properties of thermoset materials along with providing the required conductivity. Due to ultra-low working dosages in comparison with carbon black or carbon fiber, graphene nanotubes allow a wider color palette, leading to enhanced aesthetics of final products.

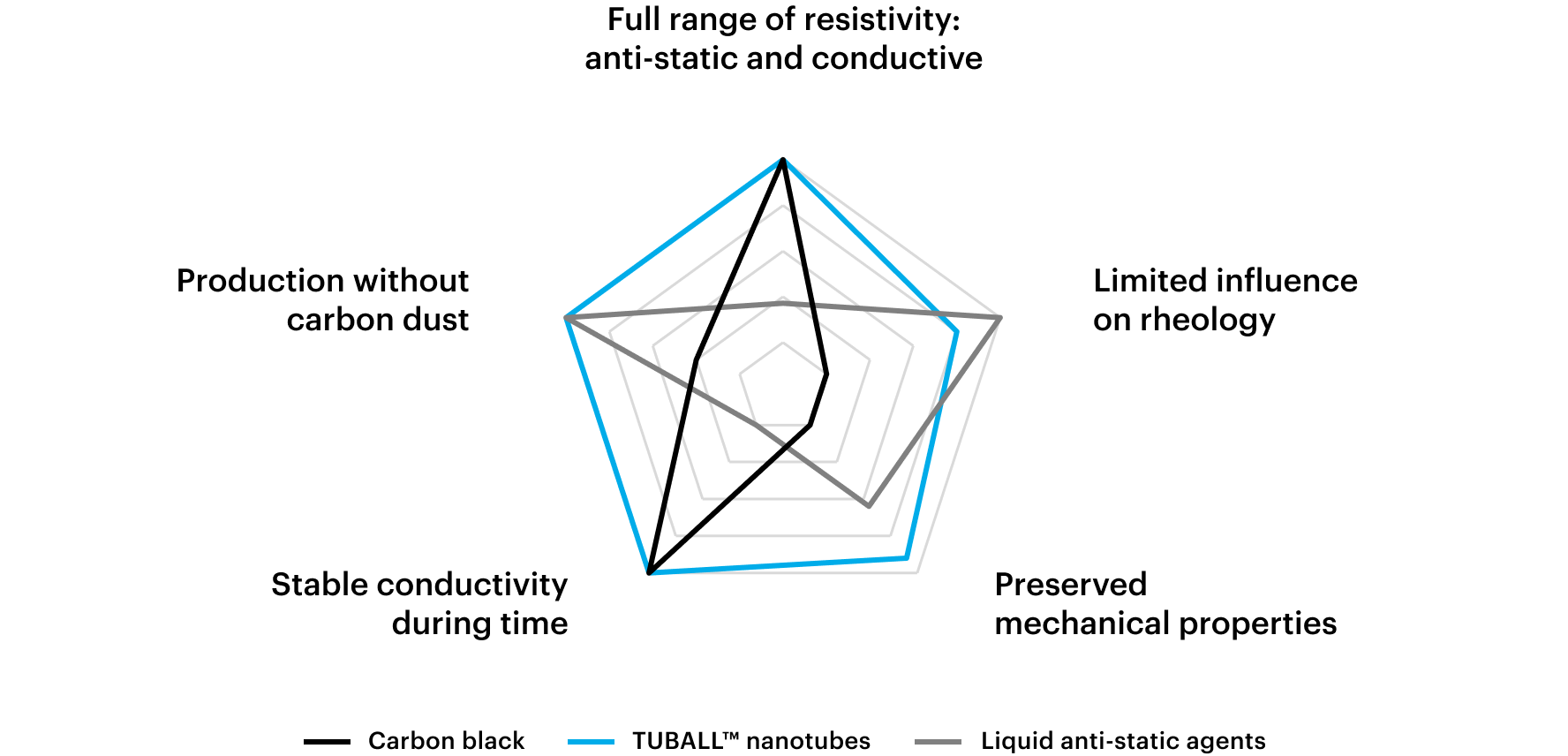

Anti-static agents: traditional vs TUBALL™

Note. This diagram provides average trends compared with other additives based on OCSiAl data. Product performance may vary depending on product type and formulation.

OCSiAl has developed the TUBALL™ MATRIX line of user-friendly concentrates for easy handling of nanotubes at a standard production facility without required changes in formulation. The anti-static masterbatch is efficient at very low loadings starting from 0.1% of the overall compound.

TUBALL™ MATRIX meets key technical requirements

| Parameter | Ammonium compounds | Carbon black | TUBALL™ MATRIX |

|---|---|---|---|

| Working dosage, wt.% | 0.2–4 | 4–12 | 0.1–0.5 |

| Resistivity range, Ω/sq | 108–1011 | 105–1011 | 104–1011 |

Influence on mechanical performance |

small negative | strong negative | none |

| Influence on rheology | none | strong negative | acceptable |

| Color opportunity | possible | none | possible |

| Application via spray technology | possible | challenging | possible |

| Dust formation during production | none | high | none |

| Resistivity independent of humidity | no | yes | yes |

| Stable resistivity over time | no | yes | yes |

Results for optimized formulation based on OCSiAl data.

Key benefits of graphene nanotubes in vinyl-ester systems include:

- Uniform conductivity – guaranteed protection from "hot spots"

- Permanent anti-static properties independent of humidity

- Preserved mechanical properties, or even enhancement of some parameters

- Flexibility in coloring the product thanks to ultra-low working loading of nanotubes

- Retained density and viscosity of the original compound

- Simple adaptation to existing production process and formulation

To check more details on products, click the cards below or contact us.

Related videos

Anti-static filament winding products: New generation technology

Conductive gelcoats: Practical recommendations for application

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample