Revolutionizing the textile industry with the multifunctionality granted by graphene nanotubes

In recent years, the textile industry has witnessed a remarkable transformation with the introduction of "smart" fabrics embedded with cutting-edge technology. These innovative textiles offer a wide range of functions that have the potential to revolutionize various aspects of our lives. From garments that protect against electrostatic discharge to fabrics that adapt to changing weather conditions, these high-value textiles provide properties essential for both technical applications and traditional uses. In this article, we delve into the exciting world of multifunctional textiles empowered by graphene nanotubes.

The integration of graphene nanotubes into textile materials has unlocked multifunctionality for the textiles used in various industries, such as medical fabrics, protective workwear, automotive textiles, and construction heating fabrics. The electrical conductivity provided by nanotubes grants these textiles highly valued functionalities.

Why does electrical conductivity matter in textiles?

Static electricity poses significant risks in numerous industries, jeopardizing the safety of individuals and equipment. Anti-static textiles play a crucial role in mitigating these risks by dissipating static charges and preventing the risk of electrostatic discharge. Several international standards are used to assess and certify the anti-static properties of textiles. The most commonly recognized standards in the industry include:

EN 1149: This European standard is specifically designed to evaluate the electrostatic properties of protective clothing.1 It consists of two parts: EN 1149-1, which specifies the test method for surface resistance, and EN 1149-2, which outlines the test method for volume resistance. The standard assesses the ability of the textile material to dissipate static charges and prevent the risk of electrostatic discharge.

ASTM D257: The American Society for Testing and Materials (ASTM) standard D257 provides a test method for determining the volume and surface resistivity of solid electrical insulating materials.2 While not specific to textiles, this standard is often used to assess the anti-static properties of fabrics and other materials. It involves measuring resistance to the flow of electric current on the surface or through the material.

ISO 1813: The International Organization for Standardization (ISO) standard 1813 defines a test method for determining the electrical resistance of flexible conductive materials.3 It outlines procedures for measuring the surface resistivity and volume resistivity of materials, including textiles. The standard helps assess the ability of a textile material to conduct or dissipate electrical charges.

AATCC Test Method 76: American Association of Textile Chemists and Colorists (AATCC) Test Method 76 evaluates the electrical resistance and surface resistivity of fabrics.4 It measures the ability of a textile material to conduct electricity and prevent the accumulation of static charges.

ISO 18080: This International Organization for Standardization (ISO) standard refers to a specific international standard in the field of textiles. It describes test methods for evaluating the electrostatic properties of fabrics.5

IEC 61340: While the International Electrochemical Commission (IEC) standard primarily focuses on the protection of electronic devices from ESD, it also addresses the role of textiles in controlling static electricity. Within the standard, specific requirements are outlined for various aspects of ESD control, including protective measures for handling electronic devices. These measures may involve the use of anti-static textiles or garments as part of an overall electrostatic discharge control program.6

EN 16350: Prepared by the Technical Committee, this standard refers to protective clothing including hand and arm protection and lifejackets. It specifies a test method and requirements for performance, marking, and information for electrostatic dissipative protective gloves to minimize explosion risks.7

These standards provide guidelines and procedures for testing the anti-static properties of textiles, ensuring that they meet specific criteria for electrostatic dissipation and safety. Here are some key reasons why textiles should be anti-static:

-

Personnel safety

In environments where static electricity can accumulate, such as manufacturing facilities, laboratories, or cleanrooms, the safety of personnel is paramount. Static charges can lead to uncomfortable shocks, which can be not only distracting but also potentially hazardous, particularly in critical work areas. Anti-static textiles help to dissipate static charges, minimizing the potential for personnel to experience electrostatic discharge (ESD) and improving overall safety.

Equipment protection

Static electricity can also damage sensitive electronic components or equipment, leading to costly repairs or replacements. Anti-static textiles help prevent static discharge from occurring near these devices, reducing the risk of damage caused by electrostatic discharge. By providing a controlled path for static electricity to dissipate, anti-static textiles safeguard the integrity and functionality of valuable equipment.

Fire and explosion prevention

In certain industries, such as those involving flammable materials or volatile substances, static electricity can pose a severe fire or explosion hazard. When static charges build up on surfaces, they can ignite flammable gases, vapors, or dust particles. Anti-static textiles help to dissipate these charges, significantly reducing the risk of fire or explosion incidents and enhancing overall workplace safety.

Cleanliness and dust control

Static charges can attract and hold dust, lint, or other particulate matter to textile surfaces. This can lead to cleanliness issues, compromised product quality, or reduced efficiency in certain processes. Anti-static textiles possess properties that repel or reduce the accumulation of dust, ensuring cleaner surfaces and minimizing contamination risks in critical environments such as cleanrooms and laboratories.

Personal comfort

Beyond safety considerations, anti-static textiles can also enhance performance and comfort for individuals working in various industries. For example, workers wearing anti-static clothing or gloves can move more freely without the concern of static buildup. Anti-static textiles can also improve comfort by minimizing static-related discomfort, such as static shocks or clinginess.

By incorporating anti-static properties into textiles, industries can effectively mitigate the risks associated with static electricity and ensure the safety of personnel, protect equipment, prevent fire and explosion hazards, maintain cleanliness, and enhance overall performance and comfort. As a result, anti-static textiles play a vital role in a wide range of sectors, from manufacturing and electronics to healthcare, clean energy, and beyond.

Functionalization of textiles by graphene nanotubes

Functionalization of textile materials refers to the process of imparting functional properties to textile and clothing materials. This can be achieved through various means, including:8

- Fiber modification: The functionalization process can involve modifying the characteristics of the fiber itself by incorporating specific polymers or additives before the spinning of the fiber.

- Construction enhancements: Functional properties can be introduced by manipulating the yarn, fabric, or material construction. This can be accomplished by using different types of fibers or incorporating multiple layers within the textile structure.

- Textile finishing: Another approach to functionalization is through textile finishing techniques. This involves applying specialized treatments or coatings to the surface of the textile to enhance its functional properties.

The unique morphology and properties of graphene nanotubes allow them to grant additional functionality to the textile through coating existing fabric or yarn or modifying the yarn itself during the spinning process. The electrical conductivity provided to the textiles by nanotubes makes it possible to achieve highly valued functionality for medical fabrics, protective workwear, automotive textiles, heating fabrics for construction, etc. Empowered by nanotubes, the textiles gain such smart properties such as ESD protection, thermal control, dust repellency, touch screen compatibility, etc.

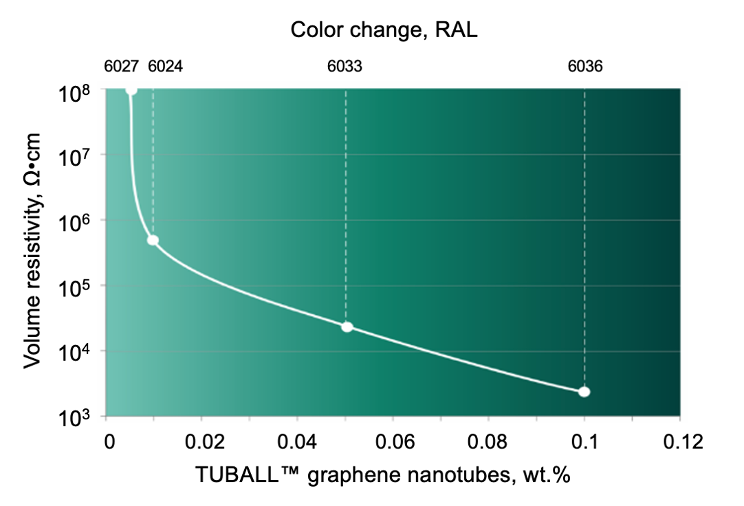

The flexibility in textile coating formulation is achieved thanks to the high efficiency of nanotubes, making it possible for them to work at the dosages starting from 0.01 wt.%. This allows manufacturers to balance and maintain other essential properties of the material, such as mechanical strength and chemical resistance. The use of masterbatches streamlines the management of graphene nanotubes during production, ensuring clean and efficient processes using standard industrial equipment.

Additionally, graphene nanotubes offer the potential for preserving the color of textiles. By adjusting the working dosage of graphene nanotubes, manufacturers can develop colored products that combine added functionality with aesthetic appeal.

Applications of “smart” properties granted by nanotubes

The integration of electrical conductivity into textiles via graphene nanotubes represents a significant breakthrough in material functionality. This new approach for the development of multifunctional textiles is suitable for diverse applications, among which are:

-

Hospital bed coverings

Synthetic mattress toppers modified with graphene nanotubes prevent dust accumulation that is unacceptable in clean rooms and avert static charge generation affecting the accuracy of electronic devices. Such new synthetic upholstery with permanent anti-static properties, enhanced durability, and retained light colors has great potential for use in static-sensitive areas and applications.

-

Car seats

Graphene nanotubes enhance the qualities of synthetic leather seat covers with an additional property that protects them from undesireable static accumulation on the surface, repels dust, and maintains a vehicle interior’s clean appearance without regular laborious cleaning. This new solution favors replacement of expensive and hard-to-maintain genuine leather with a better performing, more durable synthetic material.

-

Multifunctional protective wear

Nanotubes provide clothing with anti-static properties without impacting the original mechanical fireproof properties of the fabric. Protective wear with graphene nanotubes ensures compliance with international anti-static standards and is used for protection against sparks, splashes of molten metal, high temperatures, and risk of sudden electrostatic discharge. The additional benefit of no carbon release on the surface sets graphene nanotubes apart from alternatives such as carbon black. -

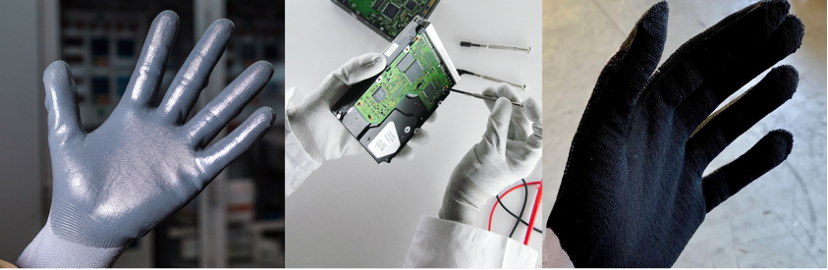

Industrial touchscreen gloves

Interactive electronic gloves enhanced with nanotubes demonstrate a combination of ESD-protective and touchscreen-compatible properties complying with EN16350 standards. The unique properties of nanotubes make it possible to maintain resistance to abrasion, alkali, hydrolysis, and microbial attack; enhanced durability and reliability; and special soft-feel effect. Touchscreen functionality facilitates the automation of industrial facilities.

-

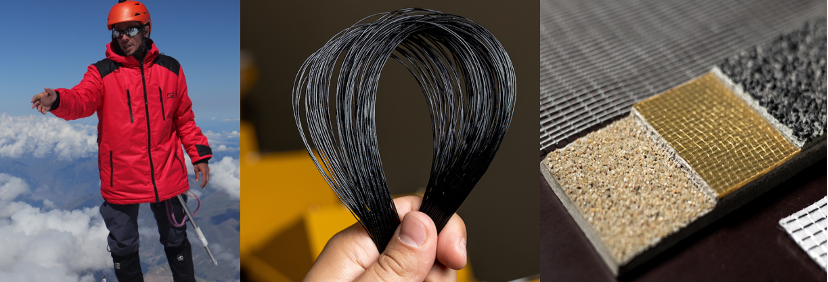

Heating construction elements

Polymer fibers with graphene nanotubes combine the flexibility of synthetic fiber with very high electrical conductivity. A heating mesh made of the innovative fibers is integrated into flexible material or complex-shaped composite elements, such as anti-icing roofs and an anti-slip coatings for bus stops. -

Heating clothing

Graphene nanotubes form a three-dimensional network that transforms textile into a heating element. Just 10 milligrams of graphene nanotubes warm mountaineering clothing in 40 seconds while preserving the flexibility of the fabric. The maximum heating temperature of the product is 45°C, which ensures comfort and safety.

Going further: potential functionalization in textile

The functionalization of textiles through the integration of graphene nanotubes represents a groundbreaking development in the field of advanced materials. By incorporating nanotubes into textile structures, scientists are unlocking a new realm of possibilities, enabling textiles to possess extraordinary functionalities beyond conventional fabrics. The latest research and development articles highlight the exciting advancements in this field, including:

-

Sensing and monitoring capabilities

The integration of graphene nanotubes into textiles enables the incorporation of sensing and monitoring functionalities.9 These functional, flexible sensors have applications in medical equipment, environmental sensing, motion detection, and the monitoring of physical parameters, contributing to energy-saving solutions.

-

EMI shielding function

Flexible fabrics embedded with nanotubes can enhance the absorption and retention of electromagnetic waves, making them effective materials for electromagnetic interference (EMI) shielding.10 These textiles offer benefits such as low cost, high shielding effectiveness, easy processability, and lightweight characteristics.

-

Flame-retardant properties

Graphene nanotubes exhibit flame-resistant and thermally anisotropic properties. By incorporating aligned carbon nanotubes into textile layers, heat can be efficiently transferred and partially redirected, protecting wearers such as firefighters from heat stress and exhaustion. Thus, textiles embedded with nanotubes exhibit improved flame retardancy and thermal stability compared to raw textiles.11, 12 -

Hydrophobic performance and washability

Graphene nanotubes can impart water-repellent features to textiles. Surface treatment of cotton fabrics with nanotubes creates an artificial lotus leaf structure, resulting in roughness on the fabric's surface.13, 14, 15, 16 Modified conductive e-textiles demonstrate excellent repeatability, washability, durability, and super-hydrophobic performance. These textiles find applications in smart clothing and flexible sensors, allowing real-time monitoring of vacuum pressures.

-

UV blocking

Graphene nanotubes possess specific absorption properties in the UV region of the electromagnetic spectrum, similar to common UV absorbers. Applying a nanotube network armor on the surface of cotton fibers enhances the fabric's UV protection capabilities.17

-

Supercapacitor function

Textile supercapacitors, novel energy storage devices, can be created by coating fibers with thin film layers of functional materials like graphene nanotubes. These supercapacitors exhibit excellent flexibility, stability, and high energy density, making conductive textiles suitable for flexible energy storage devices.18, 19

-

Textile wastewater treatment

Graphene nanotubes have commercial potential in textile wastewater treatment. Coated on a cotton fabric surface, they act as adsorbents for the removal of dyes. Stable configurations make it possible to remove natural organic matter, bacterial pathogens, and cyanobacterial toxins from water systems.20

-

Antimicrobial activity

Highly purified graphene nanotubes exhibit strong antimicrobial activity. Nanotubes' adsorption technology shows promise in removing bacteria, natural organic matter, and cyanobacterial toxins from water systems. Coating cotton fabric surfaces with nanotubes through an exhaustion method can enhance their antimicrobial properties.21 -

Reinforcement

Graphene nanotubes possess an exceptionally high modulus and strength, making them promising reinforcement materials for use in high-performance composites. The nanotubes increase the effective diameter of the fiber, providing a larger interface area for the polymeric matrix to wet the fiber.22, 23

The wear performances of textiles enhanced with graphene nanotubes unlock the possibility of producing composite materials for conventional and innovative applications, ranging from conventional apparel and sportswear to protective clothing, heating elements, automotive textiles, building coverings, geo-textiles, and biomedical textiles.

EN 1149-5: Protective clothing—Electrostatic properties—Part 5: Material performance and design requirements: http://bqw.csstgc.com.cn/userfiles/cf84af4fe79d403b893d063b8582a612/files/teckSolution/2020/06/EN%201149-5-2008.pdf.

ASTM D257: Standard Test Method for DC Resistance of Conductance of Insulating Materials: https://www-eng.lbl.gov/~shuman/NEXT/CURRENT_DESIGN/TP/MATERIALS/ASTM-D257_resistance_meas.pdf

ISO 1813: Belt drives—V-ribbed belts, joined V-belts and V-belts including wide section belts and hexagonal belts—Electrical conductivity of antistatic belts: Characteristics and methods of test: https://docplayer.net/88297297-Iso-1813-international-standard.html

4. AATCC Test Method 76: Electrical Surface Resistivity of Fabrics: https://doc.mbalib.com/view/484e7453d241e6e9d202e9c21bdb4237.html

EN ISO 18080: Test methods for evaluating the electrostatic propensity of fabrics: https://cdn.standards.iteh.ai/samples/21184/7ffe618895154fbaa53e6dfe8fc50b24/ISO-18080-3-2015.pdf

IEC 61340-5-1: Electrostatics—Part 5-1: Protection of electronic devices from electrostatic phenomena—General requirements: https://webstore.iec.ch/preview/info_iec61340-5-1%7Bed2.0.RLV%7Den.pdf

EN 16350: Protective gloves—electrostatic properties https://cdn.standards.iteh.ai/samples/34222/0afca622504b4e60aa6af008bfab7f1c/SIST-EN-16350-2014.pdf

Functionalisation of textiles—Future perspectives: https://www.semanticscholar.org/paper/Functionalisation-of-textiles%3A-future-perspectives-Almeida/4be13ddedf4ca34320ecfeb6a30cfdcc80948830

Highly conductive, washable, and super-hydrophobic wearable carbon nanotubes e-textile for vacuum pressure sensors: https://typeset.io/papers/highly-conductive-washable-and-super-hydrophobic-wearable-2ii180k08w

Hydrophobic wrapped carbon nanotubes coated cotton fabric for electrical heating and electromagnetic interference shielding: https://www.sciencedirect.com/science/article/pii/S0142941821001902

Single- and Multiwalled Carbon Nanotubes with Phosphorus Based Flame Retardants for Textiles: https://www.hindawi.com/journals/jnm/2014/727494/

Improvement the Conductivity and Flame Retardant Properties of Carboxylated Single-Walled Carbon Nanotube/Cotton Fabrics Using Citric Acid and Sodium Hypophosphite: https://www.researchgate.net/publication/319437442_Improvement_the_Conductivity_and_Flame_Retardant_Properties_of_Carboxylated_Single-Walled_Carbon_NanotubeCotton_Fabrics_Using_Citric_Acid_and_Sodium_Hypophosphite

Biobased Waterborne Polyurethane-Urea/SWCNT Nanocomposites for Hydrophobic and Electrically Conductive Textile Coatings: https://www.mdpi.com/2073-4360/13/10/1624

Superhydrophobic nano-fabrics and coatings: https://patents.google.com/patent/EP2210921A1/en

Highly conductive, washable and super-hydrophobic wearable carbon nanotubes e-textile for vacuum pressure sensors: https://typeset.io/papers/highly-conductive-washable-and-super-hydrophobic-wearable-2ii180k08w

Superhydrophobic finishing of textile fabric surface by nanocoating with carbon nanotubes: https://www.academia.edu/6897844/Superhydrophobic_finishing_of_textile_fabric_surface_by_nanocoating_with_carbon_nanotubes

Novel study of carbon nanotubes as UV absorbers for the modification of cotton fabric: https://www.tandfonline.com/doi/abs/10.1080/00405000.2011.622461?journalCode=tjti20

Flexible supercapacitors based on free-standing polyaniline/single-walled carbon nanotube films: https://www.sciencedirect.com/science/article/abs/pii/S0378775322006887

Flexible supercapacitors based on cloth-supported electrodes of conducting polymernanowire array/SWCNT composites: https://pubs.rsc.org/en/content/articlelanding/2011/jm/c1jm13722k

Textile applications of carbon nano tube: https://ijcrt.org/papers/IJCRT2109232.pdf

Adsorption of Acridine Orange and Methylene Blue Synthetic Dyes and Anthracene on Single Wall Carbon Nanotubes: a First Principle Approach: https://www.researchgate.net/publication/290120959_Adsorption_of_Acridine_Orange_and_Methylene_Blue_Synthetic_Dyes_and_Anthracene_on_Single_Wall_Carbon_Nanotubes_a_First_Principle_Approach

Processing and property investigation of single-walled carbon nanotube (SWNT) buckypaper/epoxy resin matrix nanocomposites: https://www.sciencedirect.com/science/article/abs/pii/S1359835X04000879

Elastic response of a carbon nanotube fiber reinforced polymeric composite: A numerical and experimental study: https://www.sciencedirect.com/science/article/abs/pii/S1359836809001826