Graphene nanotubes for electrically conductive silicones: stable conductivity and maintained mechanical properties

TUBALL™ nanotubes provide superior electrical conductivity to silicone compounds while retaining mechanical properties and minimally impacting the host matrix.

TUBALL™ graphene nanotubes are applied via the easy-to-use additive TUBALL™ MATRIX, which is a line of concentrates based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

TUBALL™ graphene nanotubes: Good performance on all key parameters

In contrast to other conductive agents, TUBALL™ graphene nanotubes are a versatile conductive agent offering good performance on all key parameters.

|

Parameter |

Highly conductive carbon black |

Metallic |

MWCNTs |

|

|

Working dosage |

8 wt.% |

30 wt.% |

5–10 wt.% |

4 wt.% |

|

Resistance requirements (volume Resistivity) |

<50 Ω·сm |

|||

|

Resistance achieved |

10–102 Ω·сm |

<30 Ω·сm |

<100 Ω·сm |

<50 Ω·сm |

|

Influence on mechanical performance |

strong negative |

strong negative |

strong negative |

none |

|

Influence on viscosity and extrusion rate |

strong negative |

negative |

strong negative |

acceptable |

|

Influence on rheology |

strong negative |

negative |

strong negative |

none |

|

Dust formation during production |

yes |

yes |

yes (but none in the case of a masterbatch) |

none |

|

Complicated processing (separate production unit, additional compounding stages) |

yes |

no |

yes |

no |

|

“Hot spots” (resistance varies) |

yes |

none |

possible |

none |

|

Stable resistance over time |

no |

yes |

yes |

yes |

|

Longer life cycle of compound and molded parts |

no |

no |

no |

yes |

|

Carbon release on surface |

yes |

none |

none |

none |

|

Cost of anti-static property |

comparable |

high |

comparable |

comparable |

Key benefit 1: Stability of conductive properties

When using carbon black, because of the high concentration required (10% or more) and the spherical shape of the particles, a phenomenon known in the industry as “carbon release” takes place, where the conductive additive is present on the surface of the sample.

In contrast, graphene nanotubes, owing to their greater length-to-diameter ratio, are not released to the surface.

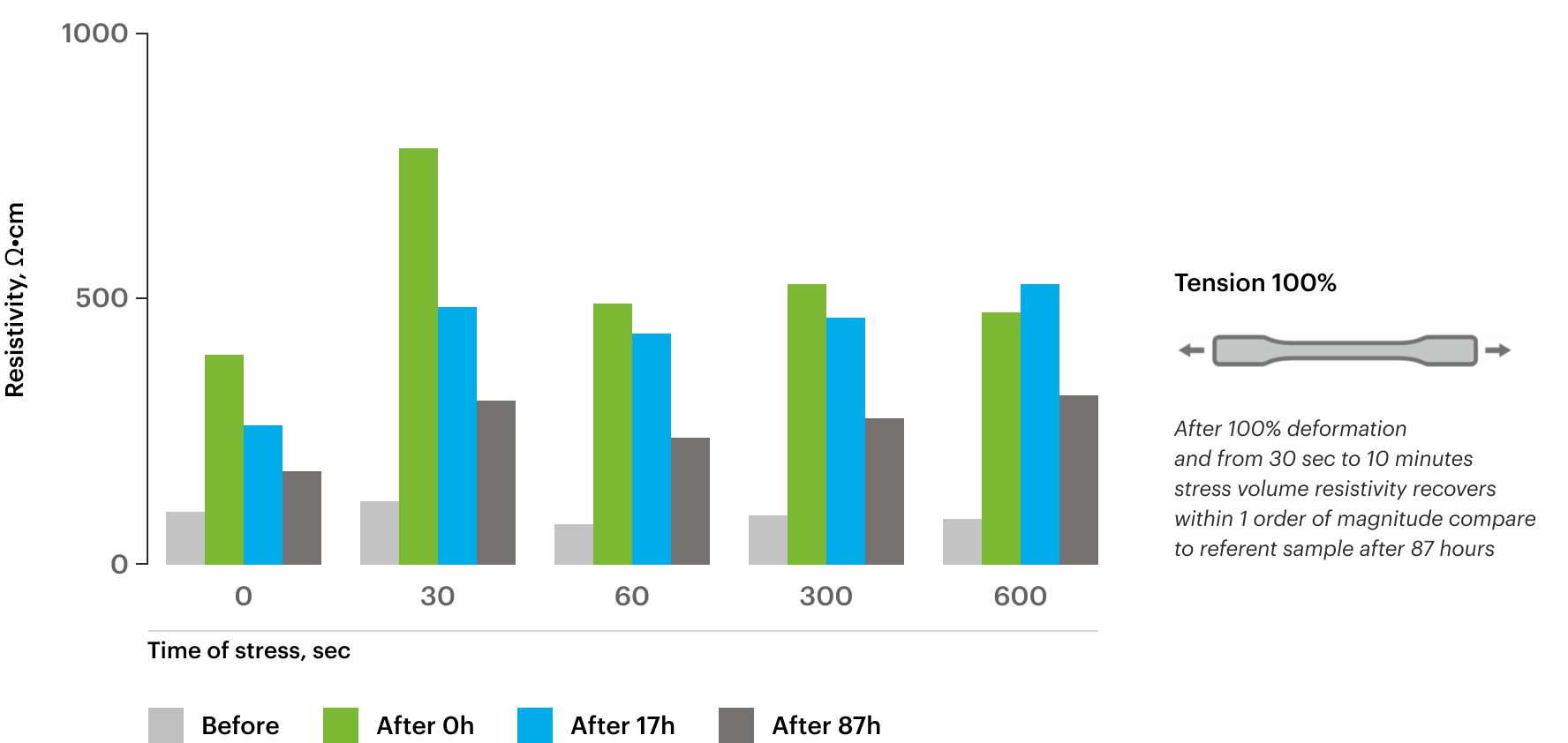

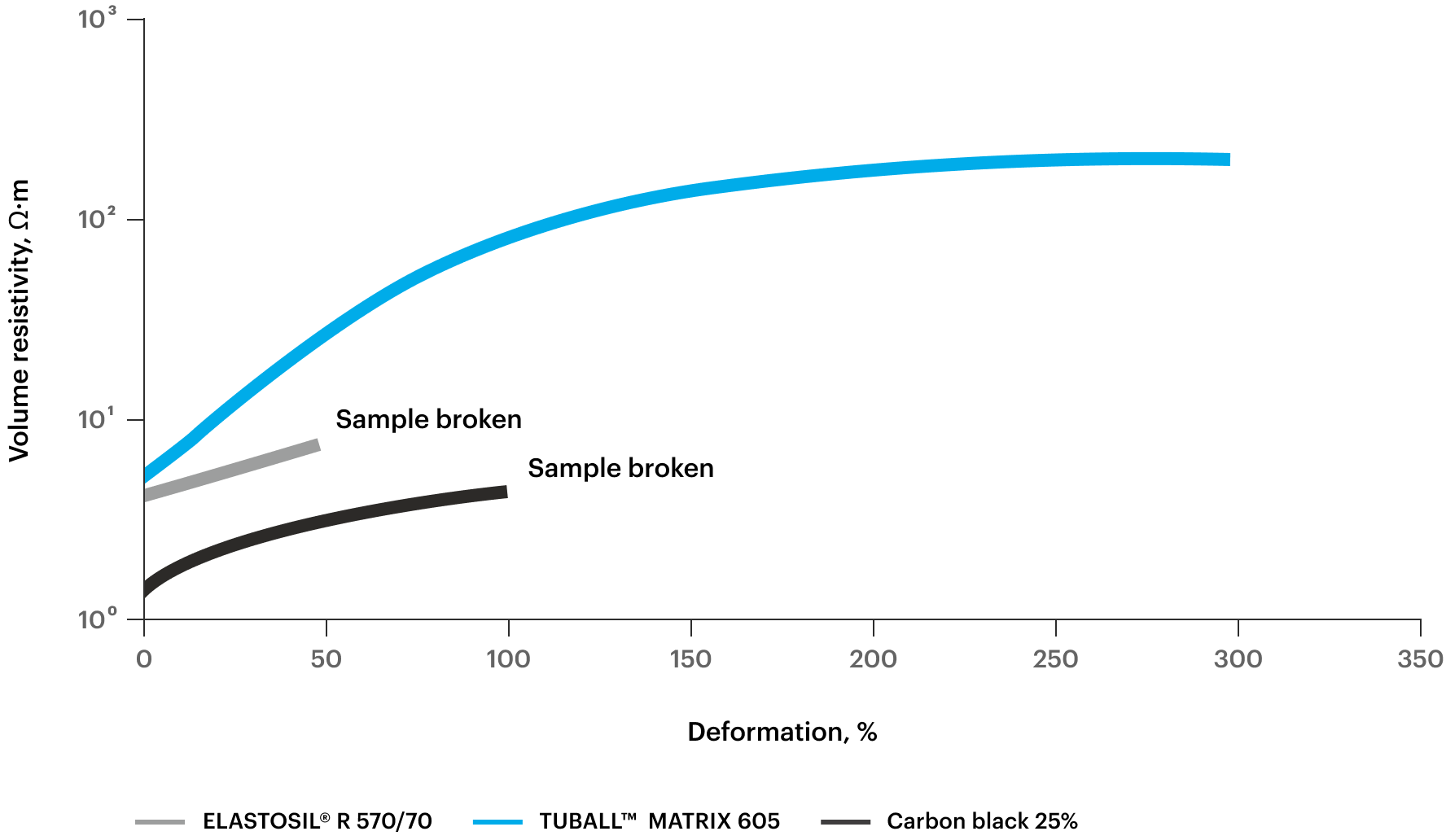

If materials will be used under conditions of deformation, it is important that stable resistivity is maintained. With TUBALL™ MATRIX, the resistivity is maintained below the target value even after stress-strain.

High dynamic pressure applications - conductive LSR with 2.5 wt.% of TUBALL™ MATRIX 601

Conductive HCR: TUBALL™ vs carbon black

Key benefits 2: Maintained mechanical properties

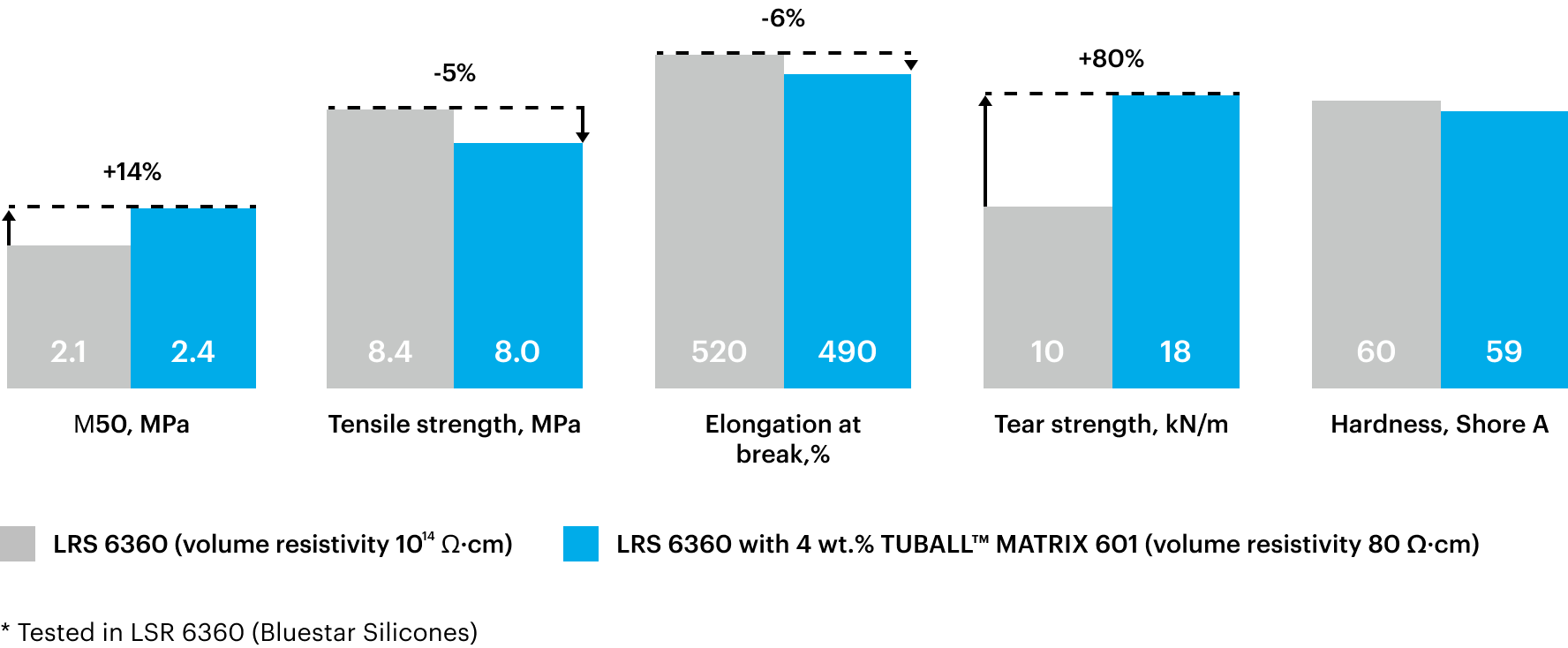

TUBALL™ nanotubes, in contrast to traditional conductive agents, minimize the impact on compound elasticity and tensile parameters, viscosity and rheological properties.

Physical properties of conductive LSR with 4 wt.% of TUBALL™ MATRIX 601

Key benefit 3: Standard processing and mixing equipment

TUBALL™ MATRIX can be diluted into compounds through the use of standard silicone compounding equipment (2-roll mill, kneader). Other approaches for masterbatch dilution may be used provided that their mixing efficiency is sufficient.

More information about the key parameters for masterbatch dilution and compound processing can be found in the processing guidelines.

Other benefits

- Extremely low loadings of TUBALL™ that preserve properties

- Permanent and uniform electrical conductivity without “hot spots”

- Maintained rheology of the uncured compound

- Minimal influence on mechanical properties including softness

Please pay close attention to processing guidelines for TUBALL™ MATRIX 601/602 for liquid silicones and processing guidelines for TUBALL™ MATRIX 605 for high consistency silicones

Download PDF version:

Or watch video instruction:

Conductive colored HCR: Processing guidelines for TUBALL™ MATRIX 605

Conductive LSR with TUBALL™ MATRIX - Processing guide

Application case

Connecting Cable Sleeve

Cable Connectors Cold Shrink Part

Flexible silicone skin electrodes, sensors

Additional resources:

Conductive Silicones - LSR, RTV, HCR and PSA

Electrical resistivity guidelines

High-performance Rubbers and Silicones with Graphene Nanotubes

Review of NAUM Nanoaugmented Materials Industry Summit 2018 in Shanghai

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample