Graphene nanotubes for FKM compounds: conductivity and prolonged durability

TUBALL™ nanotubes improve the physical and aging properties of rubbers and provide the required electrical conductivity.

TUBALL™ graphene nanotubes are applied via the easy-to-use additive TUBALL™ MATRIX, which is a line of concentrates based on polymer and plasticizer carriers and pre-dispersed TUBALL™ graphene nanotubes.

TUBALL™ MATRIX for FKM compounds

|

Material |

FKM (carbon black & mineral filler-based compounds) | ||

|

Carrier Media |

Fluoro gum |

||

|

Product |

|

|

|

|

Curing type |

Bisphenol |

Peroxide |

Bisphenol |

TUBALL™ graphene nanotubes: good performance on all key parameters

In contrast to other conductive agents, TUBALL™ graphene nanotubes are a versatile conductive agent offering good performance on all key parameters.

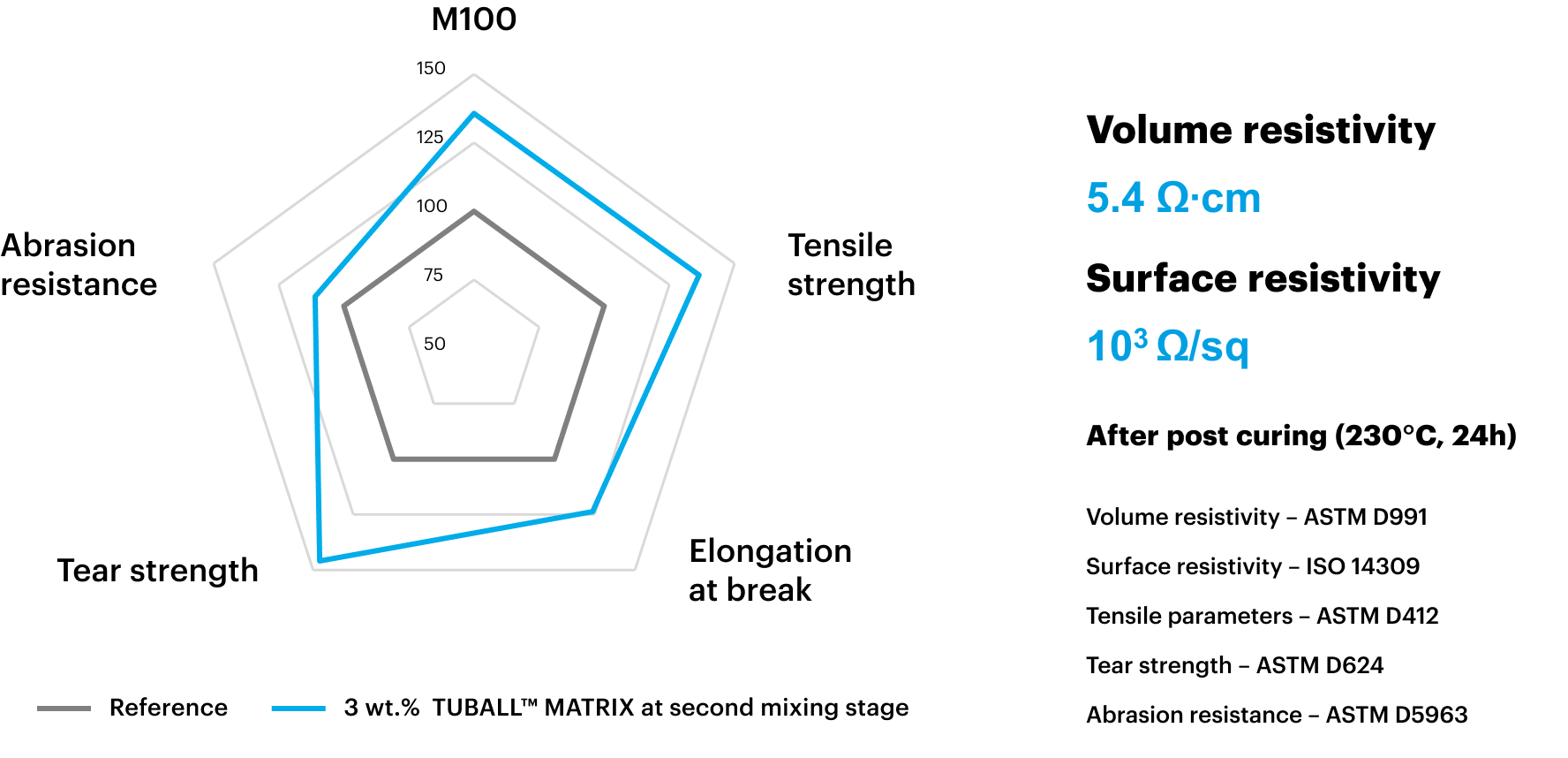

Carbon black-based formulation. Improvement of mechanical properties and conductivity

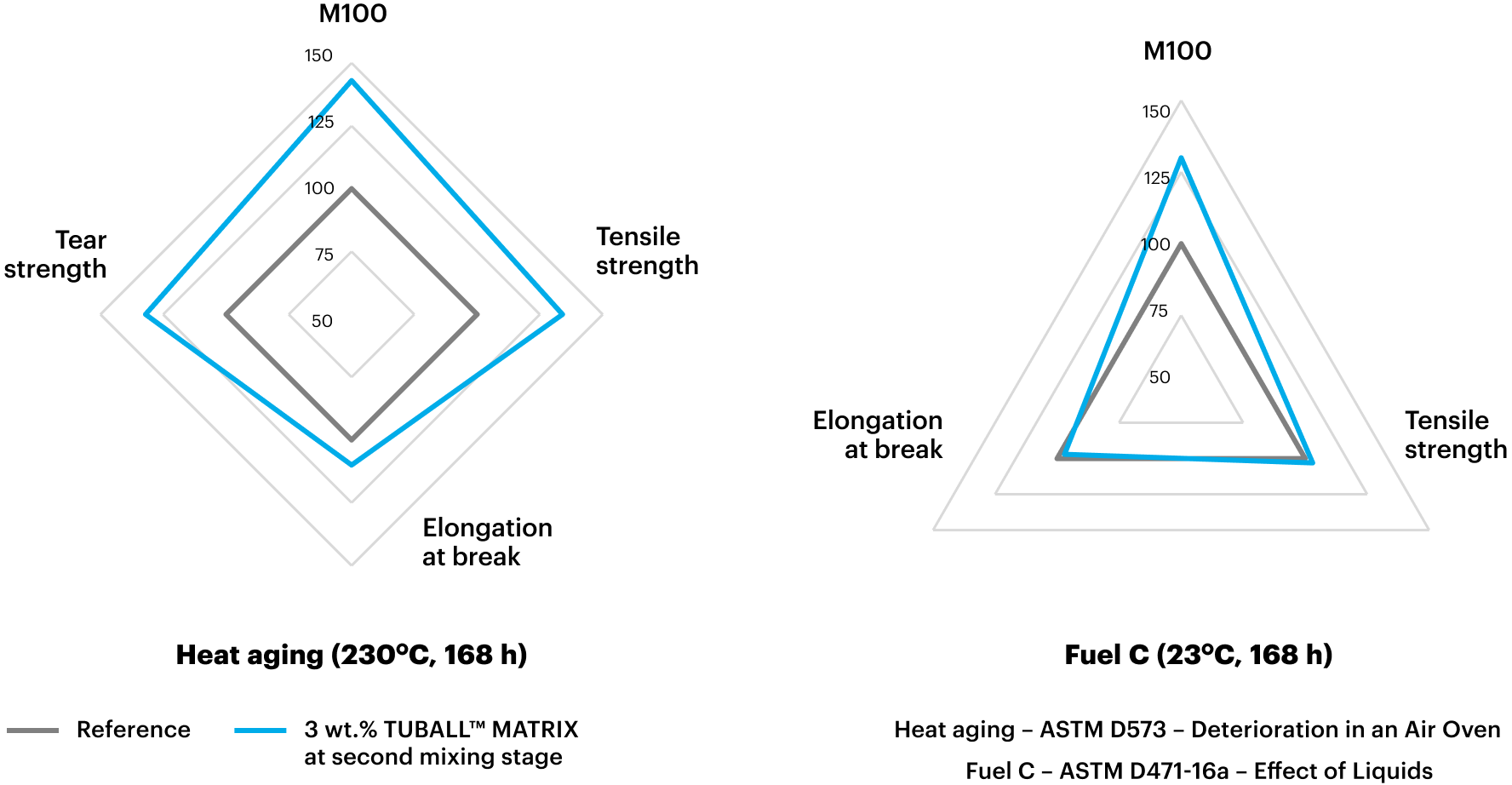

Key benefit 1: Improving mechanical stability after heat/fuel aging

Carbon black-based formulation

Key benefit 2: Retain colors without carbon release to surface

Conductive rubber elastomers are used in production areas with automated systems and sensors where color and anti-static properties are required.

When using carbon black, because of the high concentration required (10% or more) and the spherical shape of the particles, a phenomenon known in the industry as “carbon release” takes place, where the conductive additive is present on the surface of the sample.

In contrast, graphene nanotubes, owing to their greater length-to-diameter ratio, are not released to the surface.

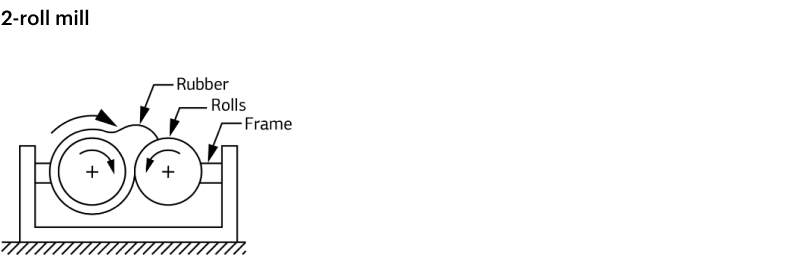

Key benefit 3: Standard processing and mixing equipment

The optimal mixing option is to introduce TUBALL™ MATRIX at the last compounding stage on a 2-roll mill.

Other benefits

- Superior conductivity

- Processing without dust

- Available for extrusion grades

- Minimum effect on hardness

- Possibility of colored anti-static non-marking compounds

Application case

FKM rubber parts

Anti-static FKM rubber parts used in robotic factories

Сonductive FKM for extrusion grades

Please pay close attention to processing guidelines for TUBALL™ MATRIX 608 beta, 621 beta, 622 beta for FKM

Download PDF version:

Additional resources:

Conductive FKM - How to reinforce mechanical properties with graphene nanotubes

High-performance fluoroelastomers with TUBALL™ (Junpei Terada, DAIKIN Industries)

Additives: Graphene Nanotubes in Fluoroelastomers Benefit Oil & Gas and Automotive Sectors

Oil & gas and automotive sectors will benefit from durable polymers with graphene nanotubes

Durable Polymers to Benefit Oil, Gas and Auto Industry

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample.