High-performance anti-static additive for electrically conductive and reinforced fluoroelastomers (FKM)

TUBALL™ graphene nanotubes are a reinforcing and conductive additive for improving the performance of two types of widely used fluoroelastomer formulations: those based on carbon black and those based on mineral fillers. Adding TUBALL™ allows manufacturers of FKM products to enhance the mechanical and aging properties and durability, and also to provide electrical conductivity.

Highly conductive, super strong, and flexible, graphene nanotubes have a record length-to-diameter ratio. These properties allow them to form three-dimensional conductive and reinforcing networks inside rubbers even at extremely low working dosages – starting from hundredths or tenths of a percent of the material’s total mass. The application of TUBALL™ in FKM, which is often used in aggressive environments, provides even more heat and fuel resistance and contributes to electrical conductivity, without affecting the elastic properties or hardness.

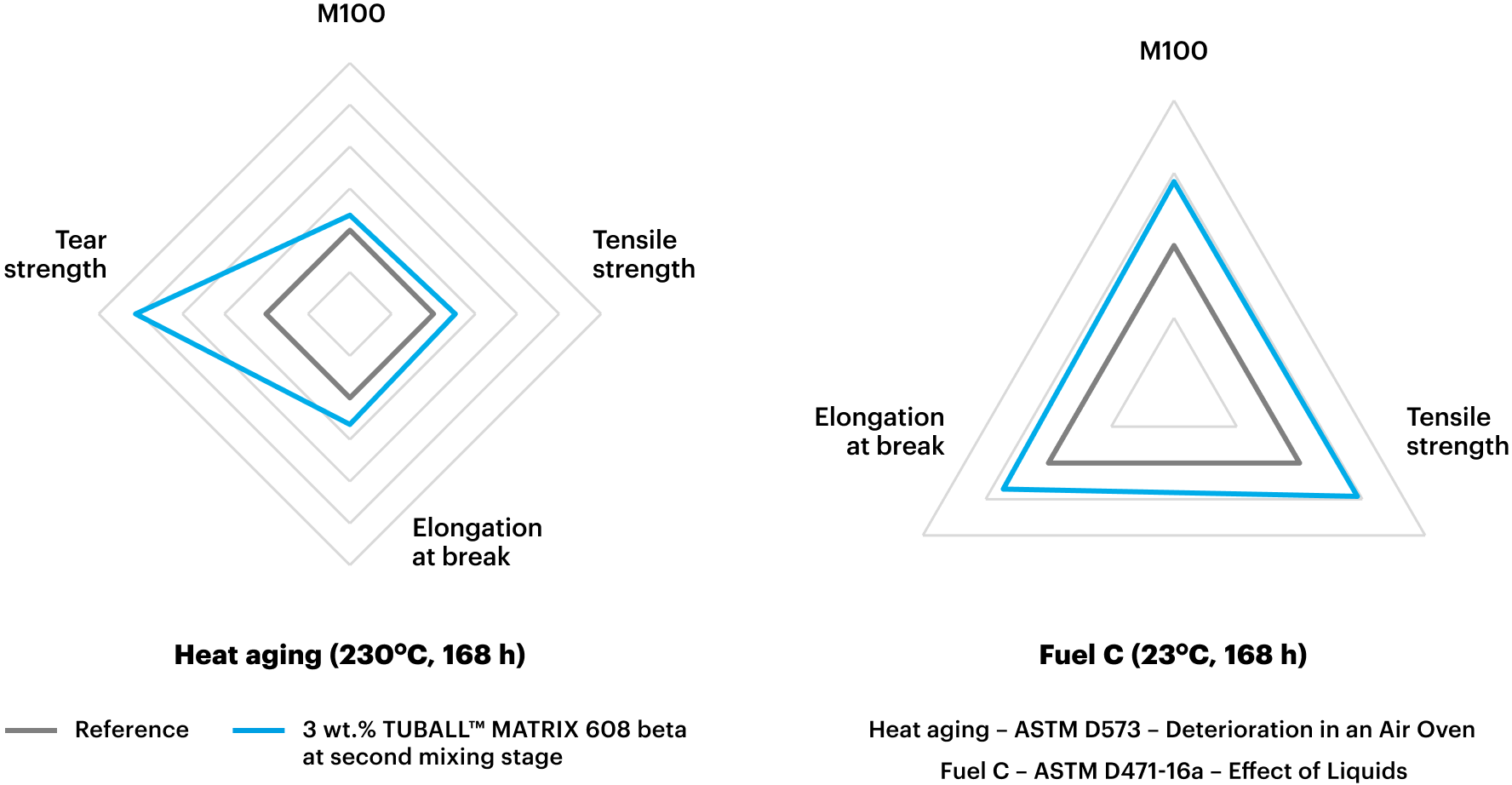

Silica-based formulation. Improvement of mechanical properties after aging

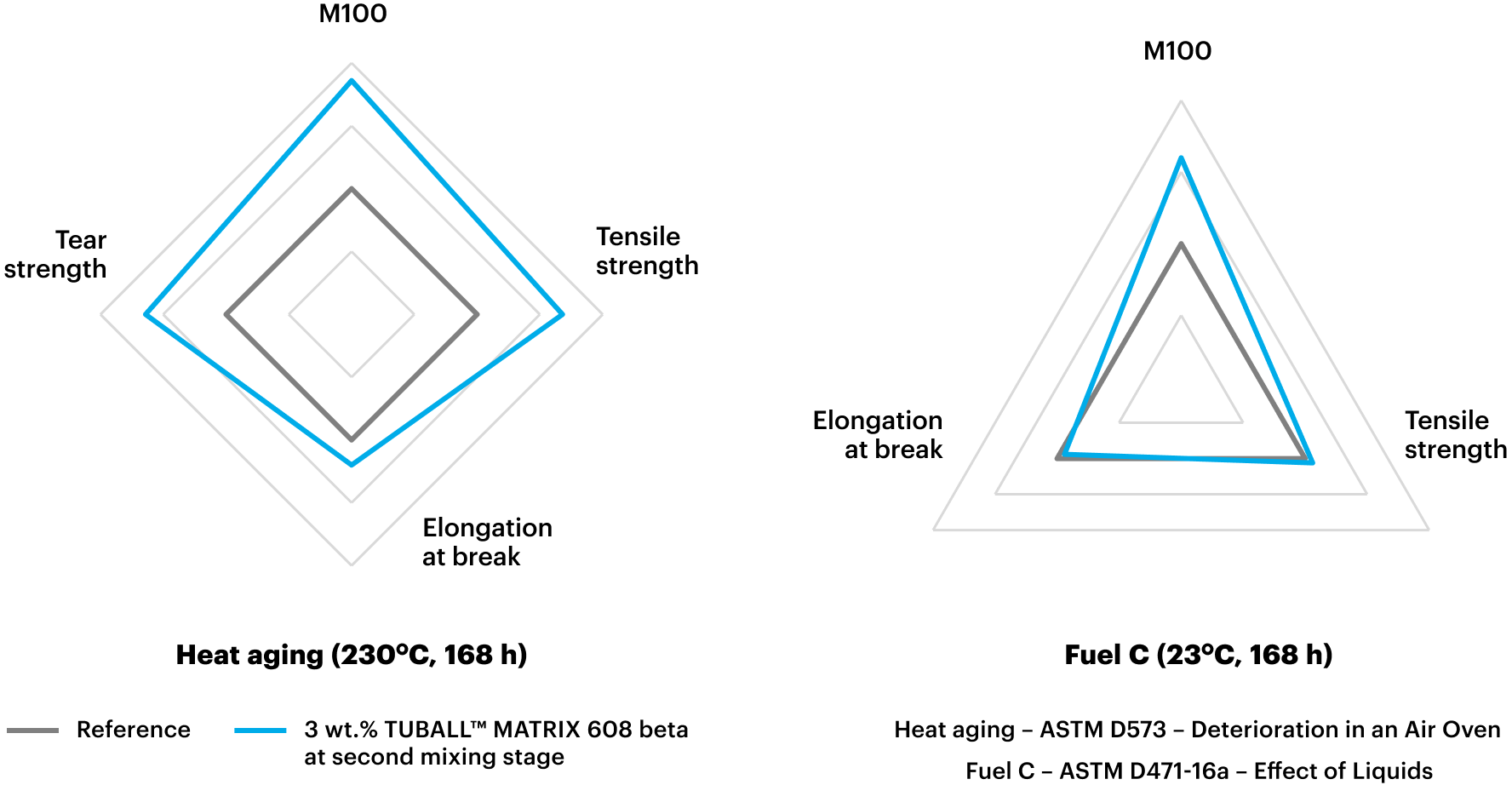

Carbon black-based formulation. Improvement of mechanical properties after aging

To simplify the handling of nanotubes and to adapt them to standard industry technological processes, OCSiAl has developed TUBALL™ MATRIX, a versatile masterbatch for fluoropolymers that is compatible with FKM carbon black and silica-based compounds.

TUBALL™ MATRIX features for FKM:

- Freedom in formulation design because of the extremely low loadings of TUBALL™

- Improved mechanical properties without drawbacks in elasticity

- Permanent and uniform electrical conductivity

- Improved mechanical stability after heat/fuel aging

- Increased durability of the final products thanks to improvements in abrasion resistance, modulus, and tear and tensile strength

- Maintained rheological properties

- Standard processing and mixing equipment

- Retained colors without carbon release to the surface for anti-static applications

Graphene nanotube modified FKMs are the top choice for heat-resistant rubber applications in aggressive environments and can be used in the oil & gas, automotive, and chemical industries, as well as in robotic manufacturing, where the combination of color and electrical conductivity are required for the identification of parts by robots.

To choose the right product for FKM, please check the selection guide below and contact us to place an order or to request additional information.

TUBALL™ for rubbers

| Product | Carrier | Composition | Target systems | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| NR | SBR | IR | BR | EPDM | NBR | HNBR | FKM | PVC | |||

| TUBALL™ MATRIX concentrates (Black flakes paste @ standard dosage 1.5%–6%) | |||||||||||

| Polymer | Fluoroelastomer + barium sulfate (CAS-No. 7727-43-7) | |||||||||

| Polymer + plasticizer | Polymer + paraffinic mineral oil | |||||||||

| Polymer + plasticizer | Polymer + TDAE oil (distillates (petroleum), solvent refined heavy paraffinic, CAS-No. 64741-88-4) | |||||||||

| Polymer | Fluoroelastomer | |||||||||

| Polymer | Fluoroelastomer | |||||||||

| Polymer + plasticizer | Polymer + polar solvent | |||||||||

| Polymer + plasticizer | Polymer + polar solvent | |||||||||

Related videos

Conductive FKM - How to reinforce mechanical properties with graphene nanotubes

Conductive FKM - Processing guide

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample