Graphene nanotubes for gelcoats: conductivity with preserved light colors and simple handling

TUBALL™ graphene nanotubes, also known as single wall carbon nanotubes, provide permanent electrical conductivity to gelcoats, while preserving light colors and allowing application via spraying.

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of anti-static masterbatches based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

For polyester and vinyl-ester resins, TUBALL™ MATRIX 204 should be used.

|

Target system |

|

|

Additive carrier |

Plasticizer + stabilizing agent |

|

Triethylene glycol dimethacrylate + ammonium salt of polyolefin-based derivatives |

|

|

Product |

|

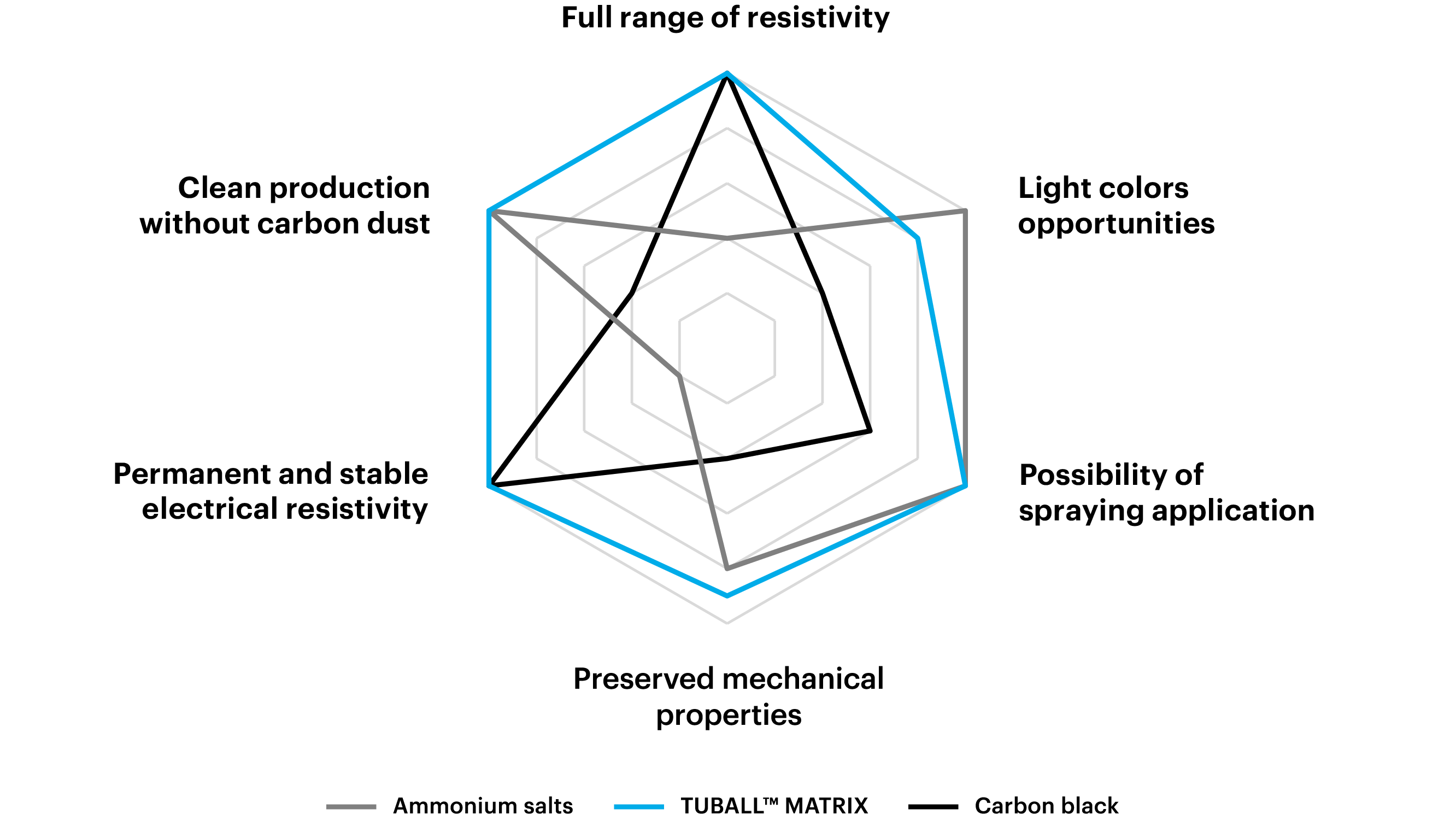

TUBALL™ graphene nanotubes are a versatile conductive agent offering strong performance on all key parameters

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

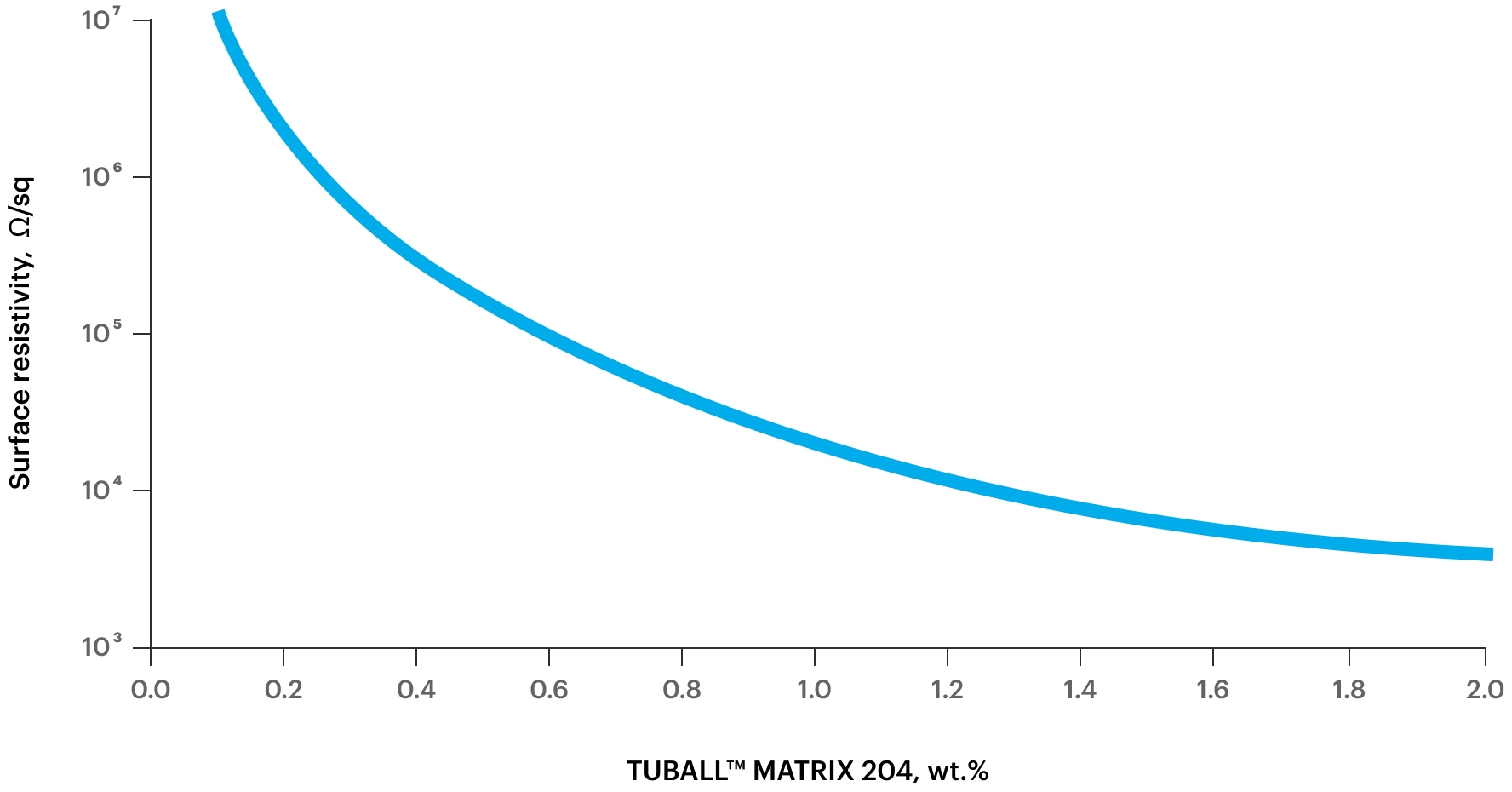

Full range of electrical resistivity

OCSiAl internal formulation ASTM D257

Easy to apply

TUBALL™ MATRIX can be processed with standard equipment that is widely used in the coatings industry.

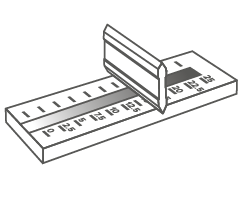

Standard single-shaft high-speed mixer

25 min total dilution time

Instant quality control with a grindometer to reach particle size ≤ 15 µm

Other benefits provided by TUBALL™ nanotubes for anti-static gelcoats:

- Limited impact on viscosity

- Low dosage gives greater flexibility in the final formulation

- Easy to apply and the low dosage makes the logistics less complex and more efficient

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of ESD additives based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

The difference between conductive and non-conductive gelcoats

Comparison parameters | Standard moldcoat without conductive additives | Anti-static moldlcoat with TUBALL™ MATRIX |

Surface resistivity | >1013 Ω/sq | >109 Ω/sq |

Application via spray technology | possible | possible |

Special anti-static wipes and spray are required during molding and de-molding procedures | required | none |

Risk of explosions and fire due to static discharge | high | minimal |

The level of anti-static properties depends on humidity of working area (in case of usage of anti-static wipes and spray) | yes | none |

Faster de-molding procedure | standard | yes |

Uncomfortable static-discharge sensations for workers | yes | minimal |

Risk of dust formation which leads to defects on composite surface | yes | minimal |

For polyester and vinyl-ester resins, TUBALL™ MATRIX 204 should be used

Application cases

Polyester Gelcoat for Electronic Equipment

Polyester Gelcoat for Blades

Polyester Moldcoat

Pay close attention to the processing guidelines for TUBALL™ MATRIX 200-x and 300-x series

Download PDF version:

Or watch the processing guidelines video:

TUBALL™ MATRIX - Processing guidelines

Conductive gelcoats for safe and efficient fiberglass molds

How to make colored conductive gelcoats: unveiling high-performance industrial technology

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample.