Graphene nanotubes for lining coatings: targeted conductivity with preserved light colors and durability

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of additives based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

Please, choose TUBALL™ MATRIX based on a carrier medium, which suites your formulation:

|

Target system |

Solvent-free epoxy |

Solvent-based epoxy |

|||

|

Additive carrier |

Plasticizer |

Surfactant |

Plasticizer & stabilizing agent |

||

Fatty acid glycidyl ester |

Alkyl glycidyl ether |

Ethoxylated alcohol |

Fatty acid glycidyl ester, ammonium salt of polyolefins-based derivative |

Alkyl glycidyl ether, ammonium salt of polyolefins-based derivative |

|

|

Product |

|

|

|

|

|

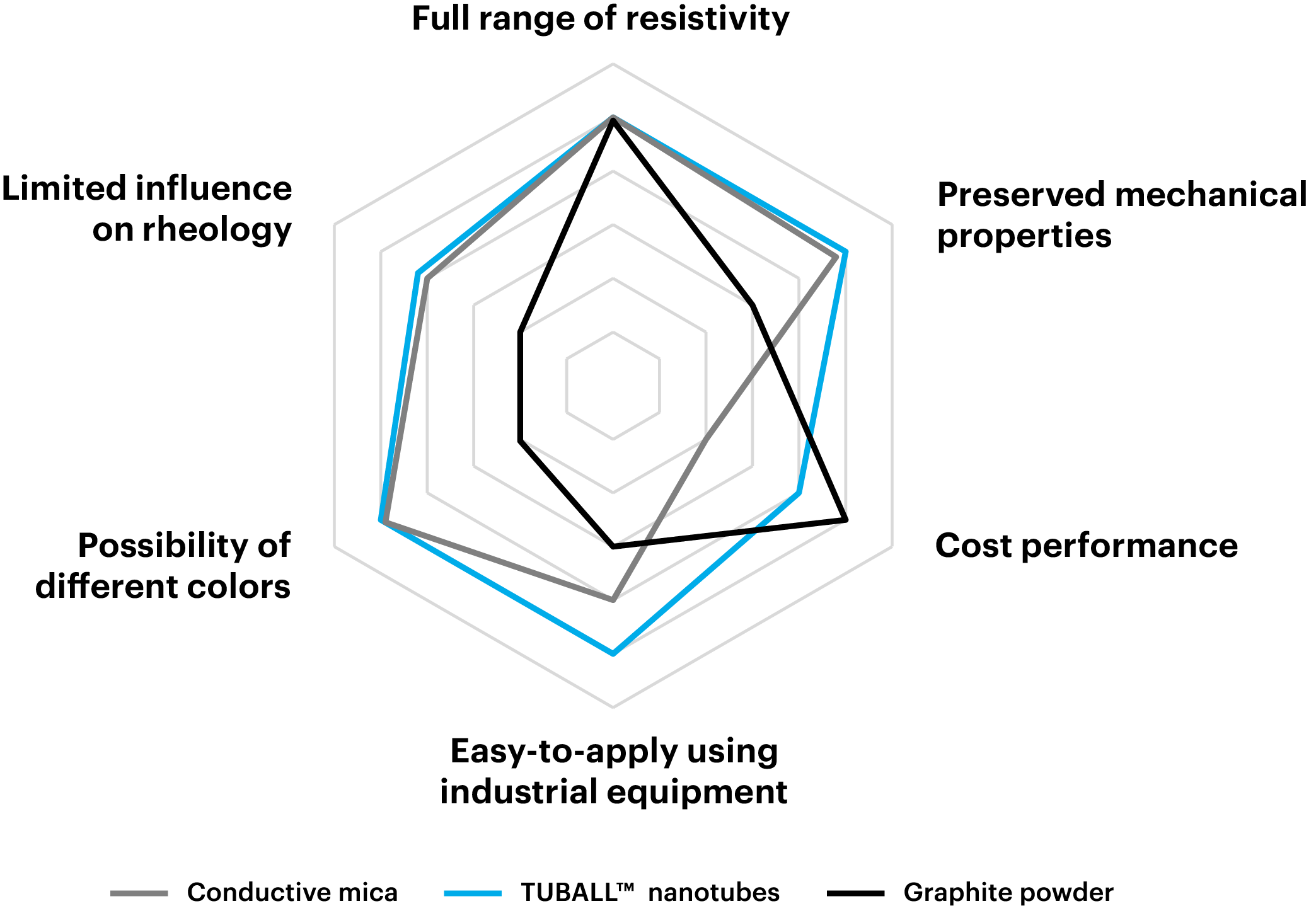

TUBALL™ graphene nanotubes are a versatile conductive agent offering strong performance on all key parameters

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

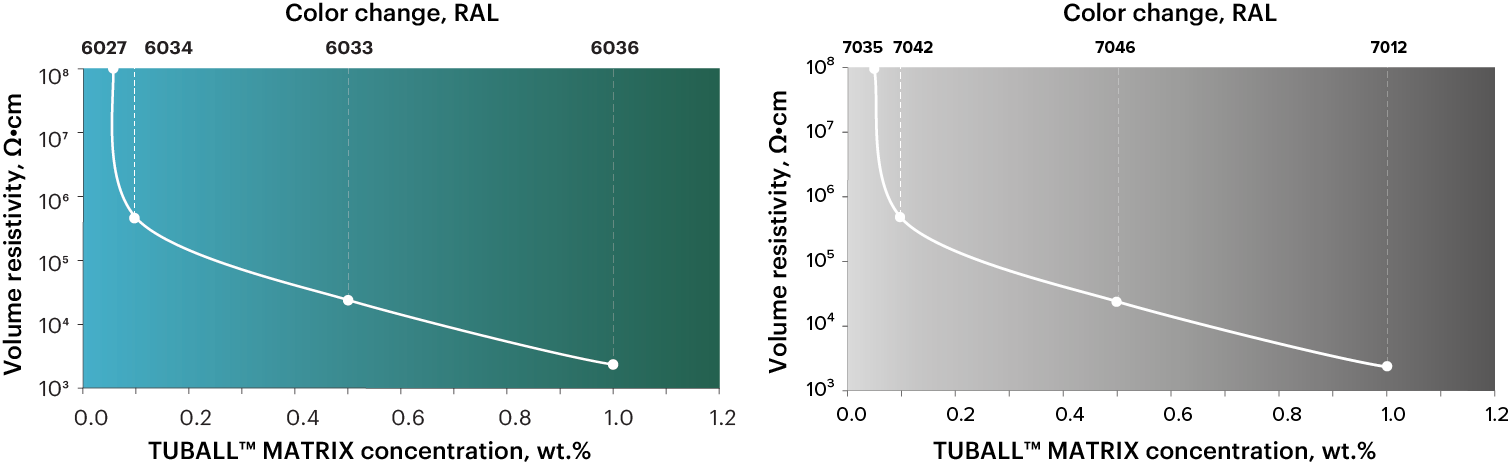

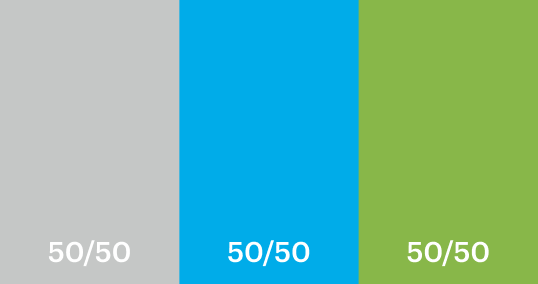

Preserved light colors

The use of TUBALL™ graphene nanotubes via TUBALL™ MATRIX additive provides a full range of electrical resistivity of 104–108 Ω·cm while allowing for a wide range of light colors to meet customer requirements, including facilitating visual inspections and more efficient servicing.

Maintained mechanical properties

TUBALL™ nanotubes, in contrast to traditional conductive agents, maintain the mechanical properties of the original non-conductive epoxy coating, resulting in a high level of durability and prolonged service life.

Preserved adhesion

ISO 2409. No detachment of coating from substrate after cross-cut adhesion test

Maintained impact resistance

ISO 6272. Full resistance to falling 1 kg weight indenter impact from 50 cm height directly to the coating and from the opposite side

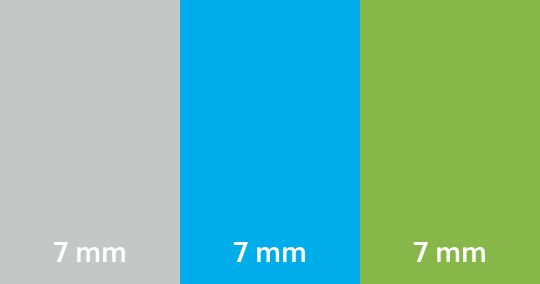

Maintained resistance to cracking

ISO 1520. Full resistance of coating to cracking and detachment from a substrate by indentation to 7 mm depth

Easy-to-apply

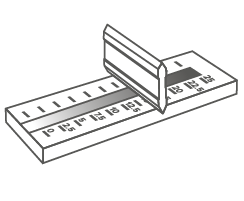

TUBALL™ MATRIX can be processed with standard equipment widely used in the coating industry:

Standard single-shaft high-speed mixer

25 min total dilution time

Instant quality control with a grindometer to reach particle size ≤ 15 µm

Other benefits provided by TUBALL™ nanotubes for lining coatings:

- Less influence on rheology compared to other conductive additives

- Low dosage gives greater flexibility in the final formulation and means less need for solvent usage

- Electrical resistivity is stable over time and independent of humidity without “hot spots”

- Consistent quality for large industrial batches

- Ease of application and low dosage makes logistics less complex and more efficient

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of additives based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

TUBALL™ MATRIX for solvent-free epoxy coatings

Application case

Lining Coating

Please pay attention to processing guidelines for 200-x and 300-x series of TUBALL™ MATRIX

Download PDF version:

Or watch the processing guidelines video:

TUBALL™ MATRIX - Processing guidelines

Additional information

Electroconductive lining and epoxy coatings - Project-based solutions

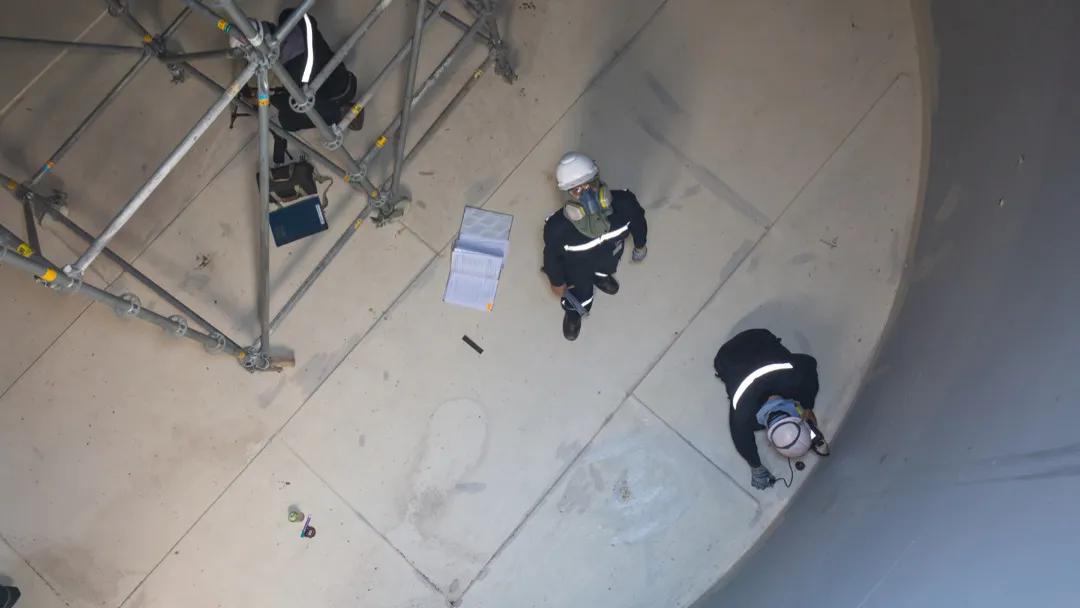

How to increase fuel storage tank safety

Conductive lining coatings applied in tanks for storage and transportation of flammable chemical products have technical requirements for both producers of lining coatings as well as for service companies. The choice of a conductive agent becomes critically important in order to provide the required electrical conductivity while maintaining the properties of the initial coating. TUBALL™ graphene nanotubes are an effective alternative to carbon black and conductive mica.

Conductive lining coatings enhanced with TUBALL™ nanotubes are widely applied in:

- Containers for flammable substances including alcohols

- Tanks for biodiesel and gasoline blends

- Storage of crude oil, fuel oil, diesel oil, jet fuel

- Fire extinguishing water and emergency tanks

TUBALL™ graphene nanotubes, also known as single wall carbon nanotubes, can be used in the production of lining coatings in compliance with the following standards and recommendations: EN 14015, TRbF 401, NFPA 77, etc.

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample