Graphene nanotubes for conductive powder coatings: preserved mechanical properties and standard processing

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of additives based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

Choose the TUBALL™ MATRIX product based on the carrier medium that suits your formulation:

|

Target system |

||

|

Additive carrier |

Polyethylene wax |

Ester of montanic acid with multifunctional alcohols |

|

Product |

|

|

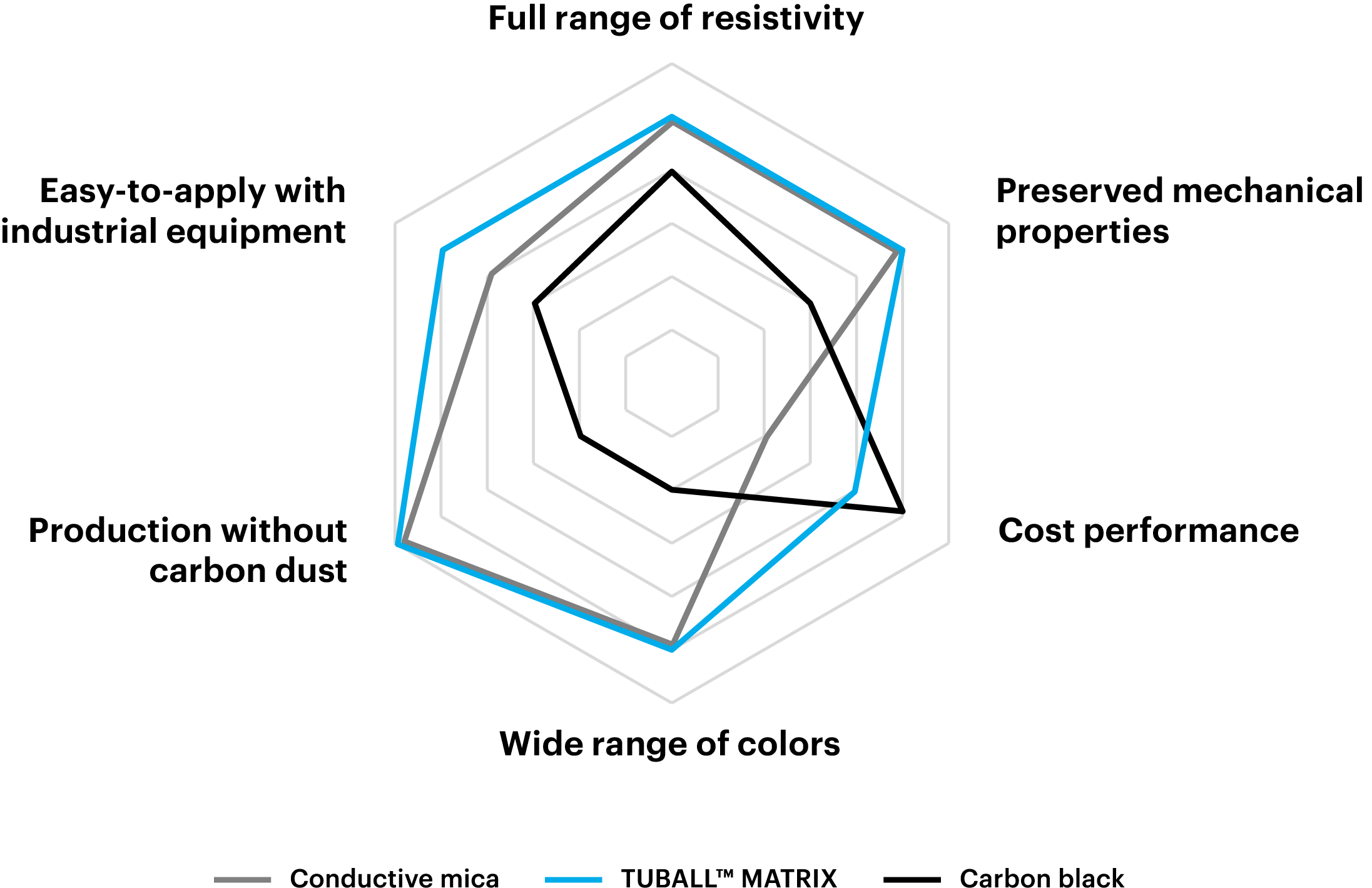

TUBALL™ graphene nanotubes are a versatile conductive agent offering strong performance on all key parameters

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

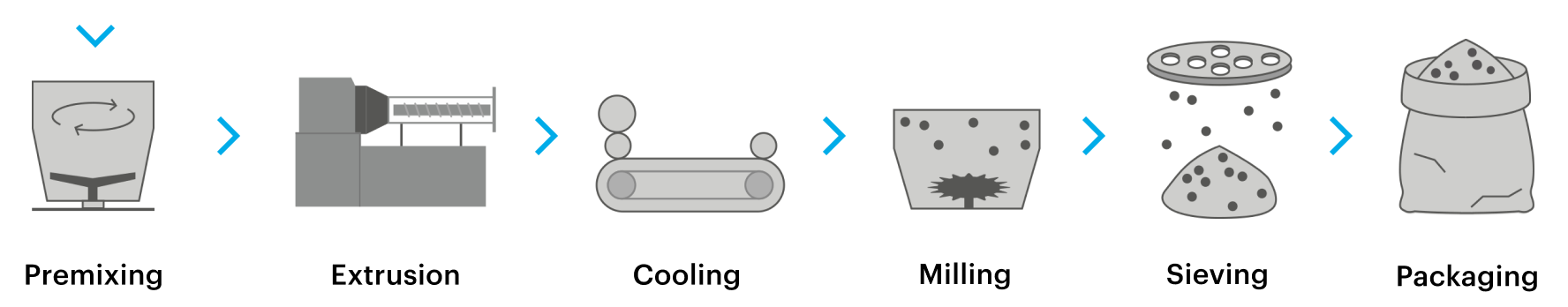

Standard processing

TUBALL™ MATRIX can be applied using standard powder coating production technology with no special adaptation.

Resins, hardeners,

pigments, additives,

TUBALL™ MATRIX

Preserved mechanical properties

TUBALL™ nanotubes, in contrast to traditional conductive agents, maintain the mechanical properties of the original non-conductive powder coating.

Preserved adhesion

ISO 2409. No detachment of coating from a substrate after cross-cut adhesion test. The same 0 class adhesion in epoxy-polyester system after addition of TUBALL™ MATRIX.

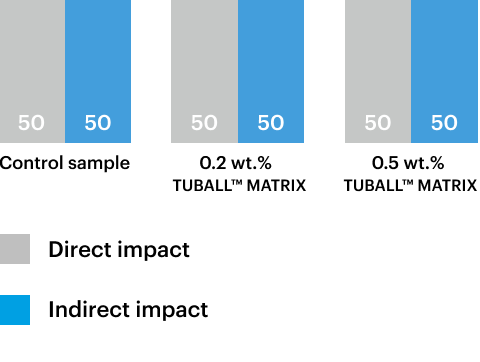

Maintained impact resistance

ISO 6272. Hybrid epoxy-polyester system. Full resistance to falling 1 kg weight indenter impact from 50 cm height directly to the coating and from the opposite side.

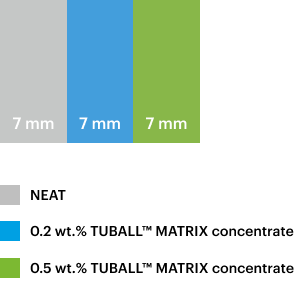

Retained resistance to cracking

ISO 1520. Hybrid epoxy-polyester system. Full resistance of coating to cracking and detachment from a substrate by indentation to 7 mm depth.

Full range of resistivity

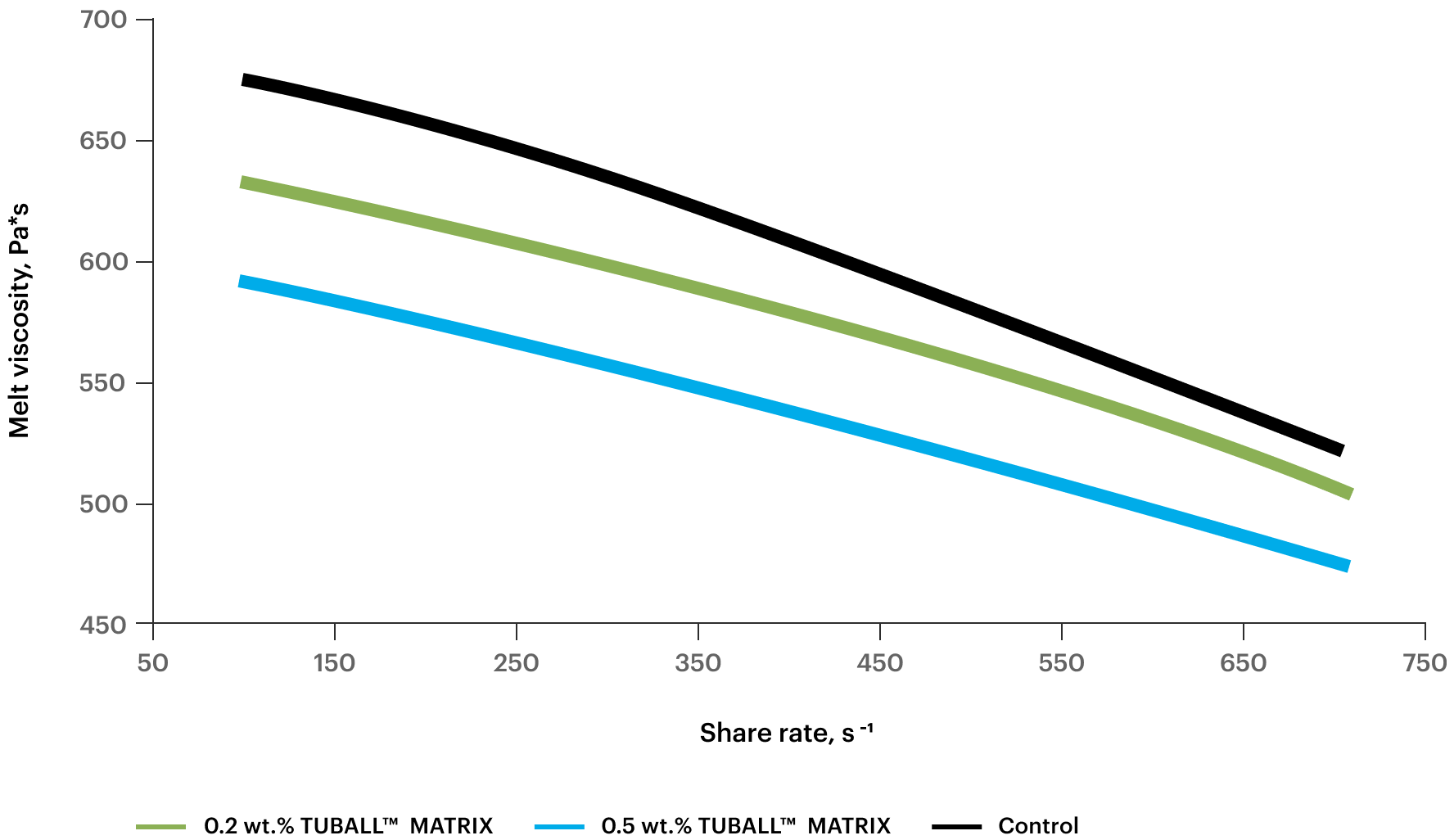

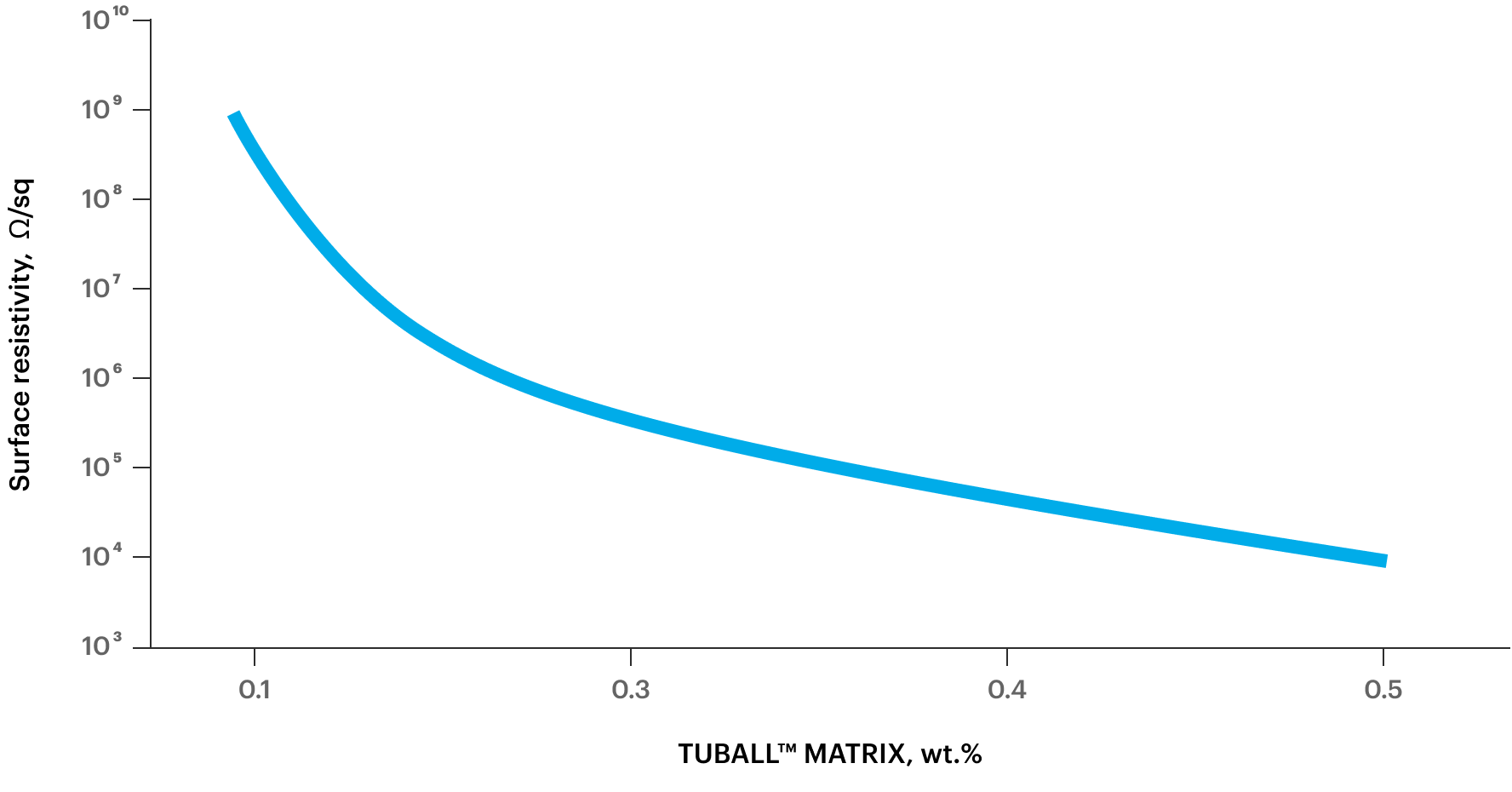

TUBALL™ MATRIX, in contrast to traditional conductive agents, does not increase melt viscosity and provides a full range of resistivity.

Influence of TUBALL™ MATRIX on melt viscosity

Percolation curve for TUBALL™ MATRIX

ISO 11443

Other benefits provided by TUBALL™ nanotubes for powder coatings:

- Wide range of colors

- Low dosage gives greater flexibility in the final formulation

- Easy-to-apply and low dosage make logistics less complex and more efficient

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of additives based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes.

Application cases

Epoxy Powder Coatings

Please pay close attention to the processing guidelines for TUBALL™ MATRIX 815/821 beta for powder coatings

Download PDF version:

Additional information

Produce anti-static powder coatings in 2.5 months without changing processing

The powder coating must be conductive to meet requirements where sensitive electronic equipment needs to be protected from electrostatic discharge due to static build-up. The coating acts as a protective film that will dissipate any static charge accumulating on the surface.

TUBALL™ graphene nanotubes are an effective alternative to carbon black and conductive mica for conductive powder coatings. Such coatings enhanced with TUBALL™ nanotubes are widely applied on ESD workstation surfaces that must be protected from electrostatic discharge. Widespread applications include:

- Electronics enclosures

- Computer workstations

- Workbenches and work surfaces

- Shelving

- Storage organizers

TUBALL™ graphene nanotubes, also known as single wall carbon nanotubes, can be used in the production of powder coatings in compliance with the IEC 61340-5-1 standard and other ATEX regulations.

Request additional materials or get a sample of TUBALL™ MATRIX