High-Performance Conductive Silicones: Types, Properties, Applications

What are conductive silicone elastomers?

Conductive silicone elastomers are a specialized class of silicon-based materials engineered to combine the flexibility of traditional elastomers with the added functionality of electrical conductivity. These materials are generally classified into three main categories based on their curing process:

- Heat-Cured Rubber (HCR). Also known as HTV (high-temperature vulcanized) silicone rubber or HCE (high-consistency elastomer), HCR silicones are processed at high temperatures or in the presence of platinum or organic peroxide catalysts. HCR has excellent resistance to high temperatures and aging. Conductive HCR materials are widely used in applications such as power and signal cables, conductive contacts, keypads, EMI shielding gaskets, printing rollers, and various industrial seals.

- Liquid Silicone Rubber (LSR). LSR features low viscosity and is ideal for high-volume production through injection molding. It’s also used to create sheets for secondary processing into end products. LSR is highly durable and resistant to cracks, scratches, and discoloration. Conductive LSR offers cost efficiency for large-scale production and is typically used in electric load control systems, electrodes, climate control components, cable terminals and connectors, and sealing systems.

- Room Temperature Vulcanized (RTV). RTV silicones are supplied as fluids or pastes that cure at room temperature into flexible rubber. RTV features ease of use, durability, flexibility, and resistance to high temperatures, acids, alkalies, and aging. Conductive types of RTV are mainly used as electrically conductive sealants and for EMI/RFI shielding—particularly in sensitive electronics and aerospace applications. The demand for these materials is on the rise, driven by the growth of electronics, optoelectronics, and photovoltaic technologies.

What are the key benefits of conductive silicone rubbers?

Like all elastomers, conductive silicones can stretch under stress and return to their original shape once the stress is removed. What sets silicone elastomers apart is their silicone backbone, which offers enhanced performance in extreme environments. When infused with conductive fillers, they gain the ability to conduct electricity, unlocking a wide range of advanced applications. The key benefits include:

- Electrical conductivity. Conductive silicones provide stable, reliable electrical performance across a range of resistivity levels: from anti-static grades with volume resistivity of 10⁶–10⁸ Ω·cm to ESD (electrostatic discharge) grades at 10³–10⁶ Ω·cm and EMI shielding grades at 10¹–10³ Ω·cm.

- Mechanical flexibility and long-term stability. These materials offer excellent flexibility, allowing them to conform to complex geometries while maintaining their electrical and mechanical performance over an extended service life.

- Broad temperature resistance. Conductive silicones operate effectively across a wide temperature range, typically from −60°C to +200°C or higher, without degradation of their structural or conductive properties.

- Superior environmental and chemical resistance. Conductive silicones demonstrate outstanding resistance to environmental factors such as UV radiation, ozone, humidity, and various chemicals, making them suitable for both indoor and outdoor applications.

- Long-term cost efficiency. Although the initial cost may be higher compared to conventional materials, the extended durability and reduced maintenance requirements of conductive silicone rubbers lead to lower total cost of use.

- Customizability for targeted performance. Formulations can be engineered to meet specific performance criteria, including tailored levels of electrical conductivity, thermal resistance, and chemical compatibility—ensuring optimal performance in demanding applications.

- Biocompatibility for medical use. Conductive silicone is biocompatible, making it suitable for use in medical devices that come into direct contact with the human body, such as wearable sensors, electrodes, and diagnostic equipment.

What enables electrical conductivity in silicone?

Conductive silicone is typically formulated by incorporating conductive fillers into a silicone rubber matrix. Common fillers include:

- Carbon-based materials. Such fillers as carbon black, graphite, graphene nanoplatelets (GNPs), and carbon nanotubes (CNTs) provide electrical conductivity and are widely used due to their effectiveness and availability. [2]

- Metallic fillers. They include various metallic particles as silver (Ag), nickel (Ni), copper (Cu), titanium diboride (TiB₂), and many others. These metals offer high conductivity and are used in applications requiring superior electrical performance; however, they are challenging to compound in silicones, decrease elastic behavior, and are not cost-effective. [3]

- Hybrid fillers. Combinations of carbon-based and metallic fillers can be used to achieve a balance between conductivity, mechanical properties, and cost. [2]

There are several processing methods for manufacturing conductive silicone rubber. They include mixing/blending, filtration, ion implantation, and in-situ formation. Usually, several key steps are required to ensure uniform dispersion of conductive fillers and optimal performance, ending with curing using heat or catalysts to solidify the rubber. [4], [5], [6] Additionally, various additives are incorporated to tailor the properties of conductive silicone rubber. Among them are catalysts to initiate cross-linking during curing; surfactants to aid in the dispersion of fillers within the silicone matrix; inhibitors to control the curing process and extend the working time of the material; and foaming agents to create a cellular structure in applications requiring lightweight materials. [7], [8]

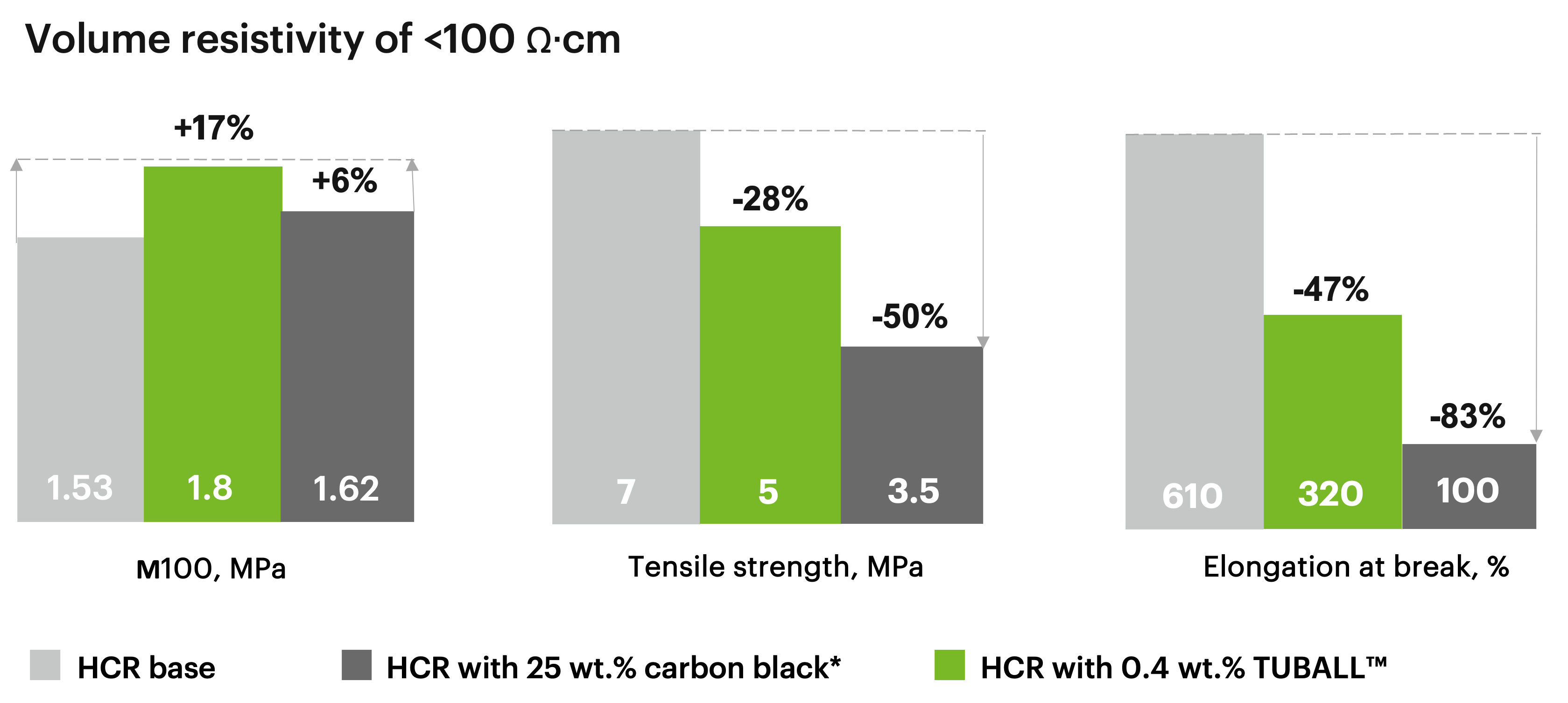

The key to combining superior conductivity and original silicone performance

Conventional solutions for achieving electrical conductivity in silicone rubber come with significant drawbacks. For example, carbon black requires a high dosage (5–25 wt.%), causes carbon release on the surface, is only available in black, and negatively affects mechanical performance. It can also result in insulative “hot spots” on the surface. According to silicone manufacturers, producing conductive compounds with carbon black is quite challenging, and only a few companies can manage it due to carbon black dusting. This often necessitates the involvement of a third party to integrate the conductive filler, adding extra processing costs. Moreover, high carbon black concentrations significantly impair the physical and mechanical properties of the final product.

Using graphite as a conductive filler also impacts material performance due to the high loading required—often 20–40 wt.%. This stiffens the silicone matrix, reducing elongation at break, softness, and flexibility. Graphite’s dark gray to black color restricts color options, which is a limitation in medical, consumer, or aesthetic applications. It is also denser than many other carbon fillers (such as carbon black or carbon nanotubes), resulting in a heavier final product—undesirable for lightweight or wearable electronics.

Metal-based fillers pose additional challenges. They are prone to oxidation, which reduces conductivity over time and shortens product lifespan. These fillers are also rigid, diminishing the flexibility and elasticity of silicone rubber. Moreover, they can increase the final material’s density and cause wear on processing equipment—both concerns for lightweight or precision applications.

Comparison of conductive fillers in silicone rubber

| Filler type | Typical loading | Electrical conductivity | Mechanical impact | Color options | Processing considerations | Stability & longevity |

| Carbon black | 5–25 wt.% | 106–109 Ω•сm | Reduces flexibility and elasticity | Black only | Dusty; may require third-party processing; increases viscosity | Surface carbon release; potential for insulative “hot spots” to develop over time |

| Graphite | 20–40 wt.% | Moderate | Stiffens matrix; reduces softness | Dark gray to black | High loading increases weight; limited dispersion; affects processing | Prone to agglomeration; inconsistent conductivity |

| Metal fillers (paste form) | 10 wt.% | 105–107 Ω•сm | Rigid; reduces flexibility | Limited | Increases density; causes equipment wear; processing challenges | Susceptible to oxidation; conductivity may decrease over time |

| Multi wall carbon nanotubes (MWCNTs) | 3–10 wt.% | 105–107 Ω•сm | Moderate stiffening; may reduce elasticity | Black only | Prone to agglomeration; requires intensive dispersion; difficult to process uniformly | Can degrade under stress; stability of conductivity highly dependent on dispersion quality |

| Graphene nanotubes (SWCNTs) | 0.5–5 wt.% | <10 to 1010 Ω·cm | Maintains or improves flexibility | Wide range | Supplied as pre-dispersed concentrates, compatible with standard mixing processes | Stable conductivity over life cycle; resistant to humidity and stress |

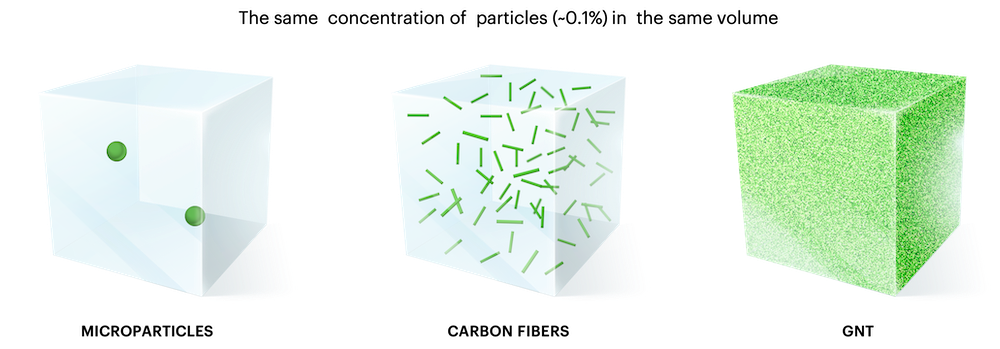

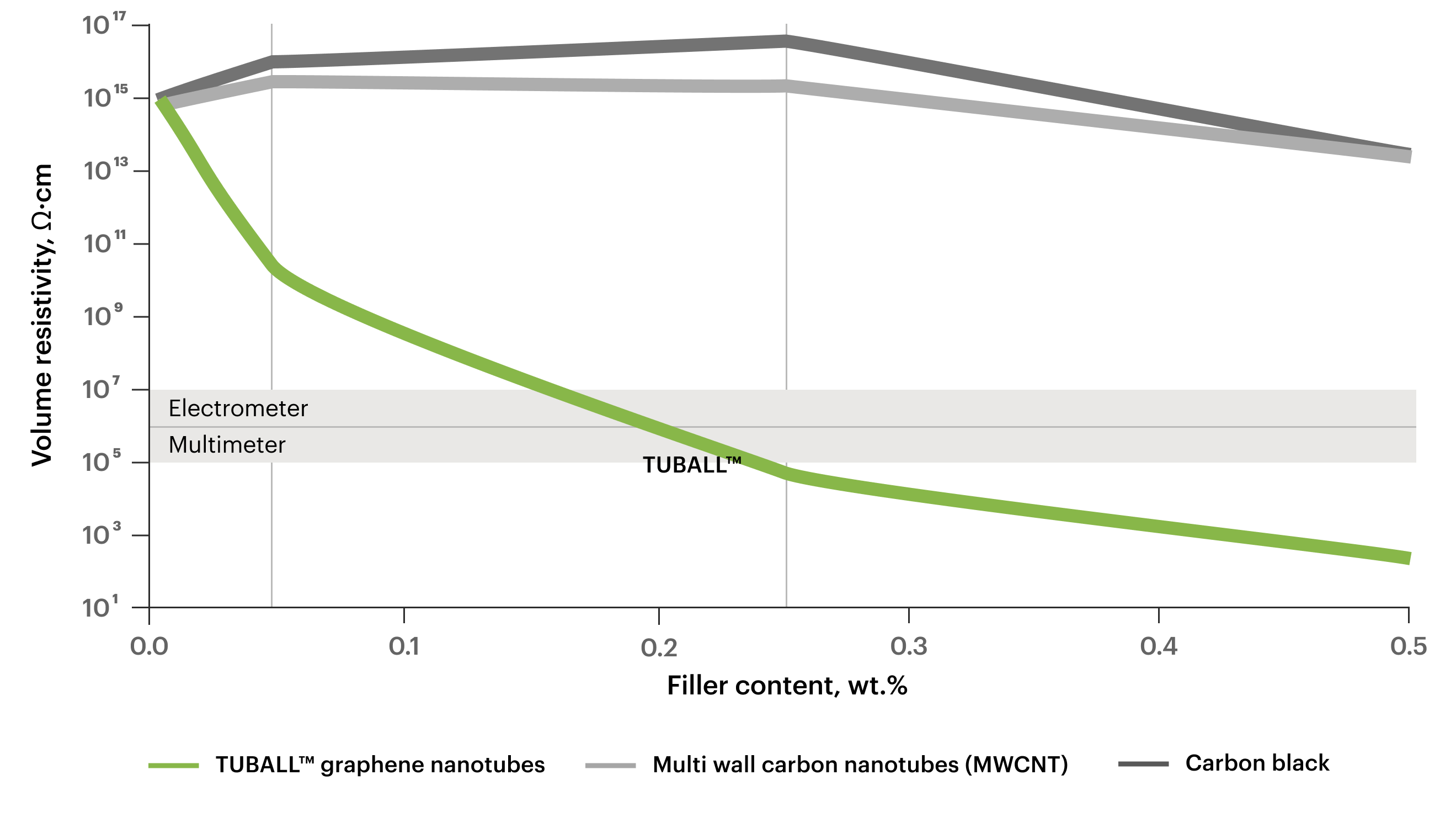

All of these challenges can be solved by using an advanced conductive agent—graphene nanotubes. Modern industrial requirements demand materials with stable electrical conductivity, good mechanical strength, high elasticity, low hardness, vibrant color options, and non-marking surfaces. Graphene nanotubes, also known as single wall carbon nanotubes (SWCNTs), combine high electrical conductivity, excellent reinforcement properties, and a unique “nanospring” effect. Their morphology allows them to form an effective 3D conductive network within silicone at ultralow concentrations, making it possible to:

— Provide stable electrical conductivity at ultralow dosages. Graphene nanotubes enable silicone rubber to achieve permanent, stable conductivity across the range of 10 to 1010 Ω·cm. Unlike other conductive additives, graphene nanotubes form a continuous 3D conductive network at just 0.5 wt.%, enabling silicone to reliably conduct electrical current.

LOW WORKING DOSAGE FOR SUPERIOR CONDUCTIVITY

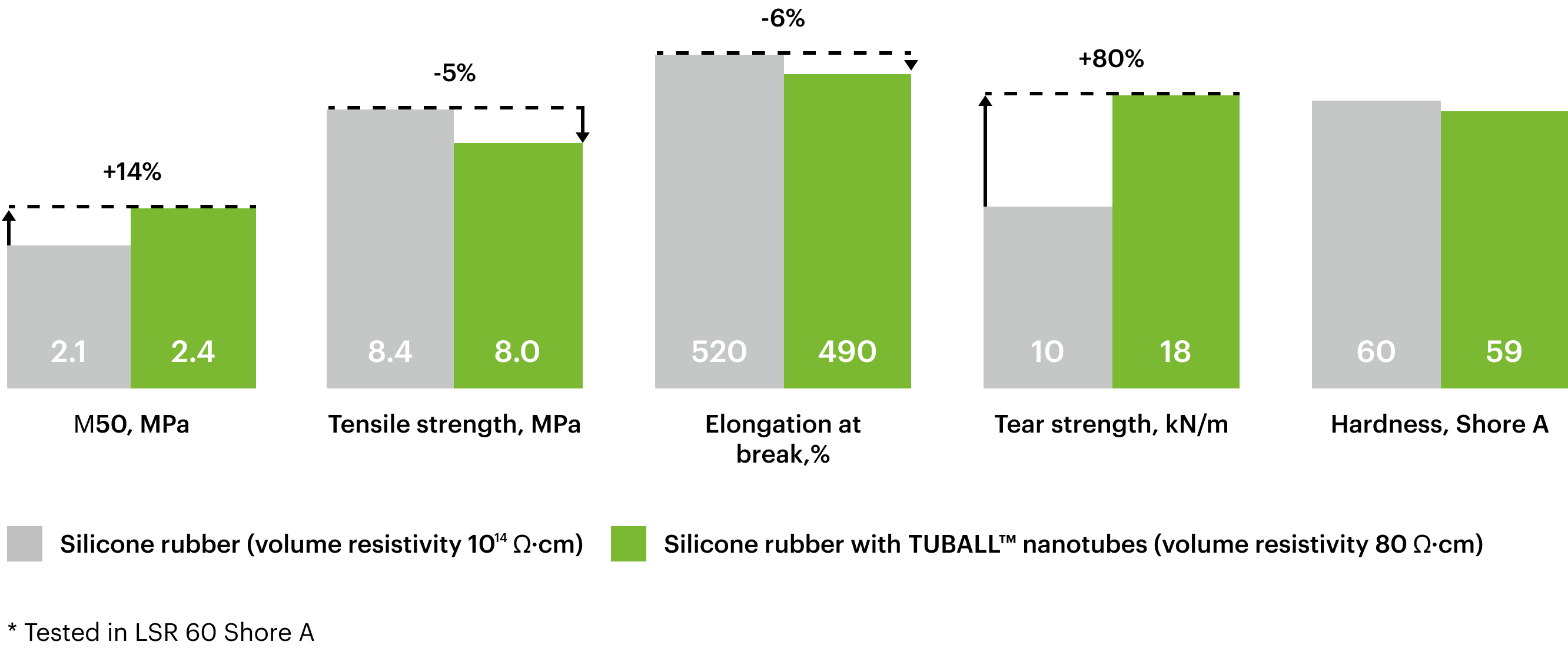

— Maintain and even improve key mechanical properties. Thanks to the ultralow nanotube working dosage, silicone retains its original flexibility, strength, and low hardness. In skin contact electronic devices, this ensures strong adhesion to the body, reduces signal loss and noise, and maintains comfort. These properties are nearly impossible to achieve using conventional conductive agents like carbon black, metal fillers, or carbon fibers, which require high loadings and lead to compromised performance.

CONDUCTIVITY & PRESERVED KEY PROPERTIES

PERFORMANCE COMPARED WITH CONVENTIONAL FILLERS

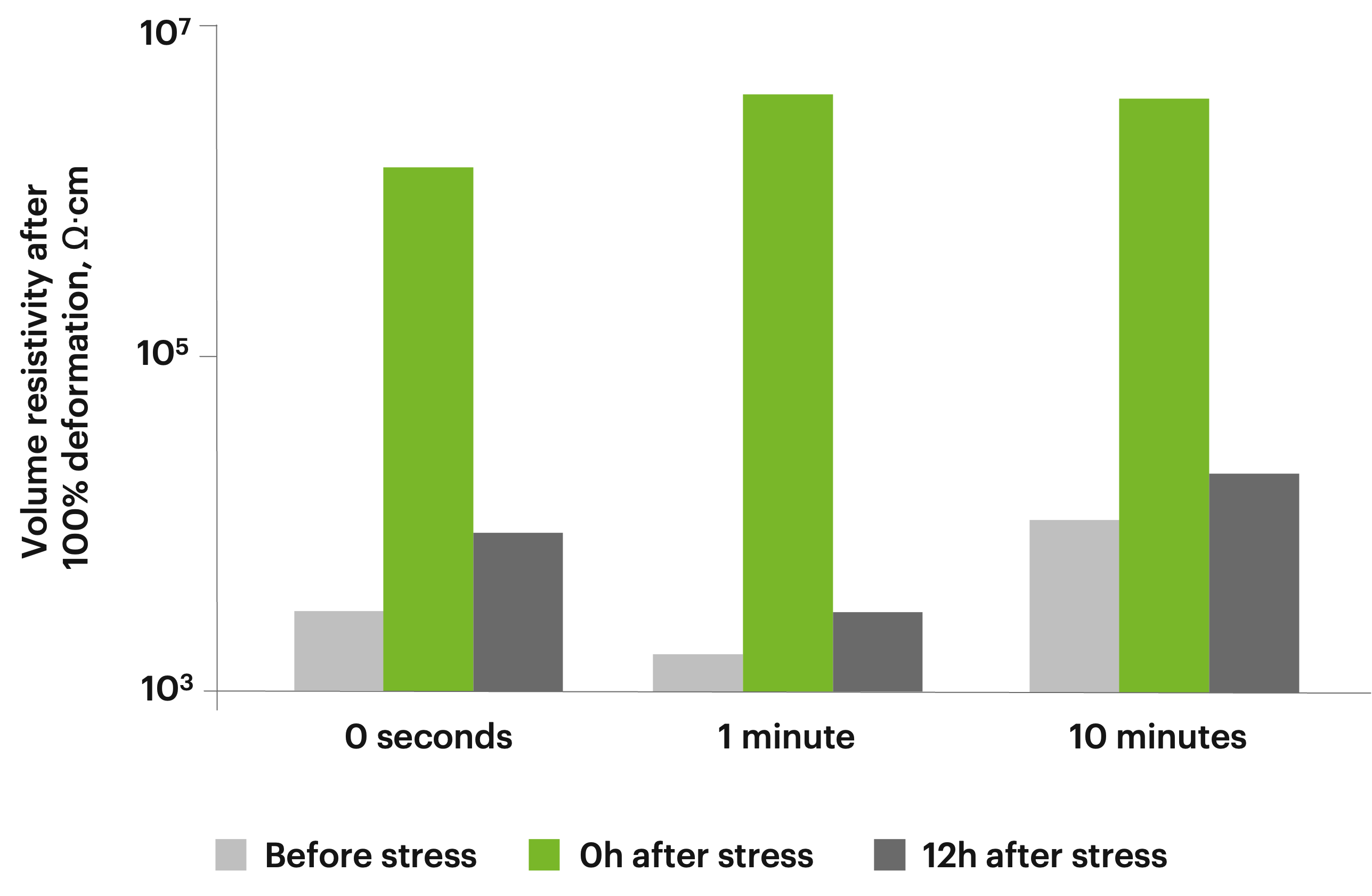

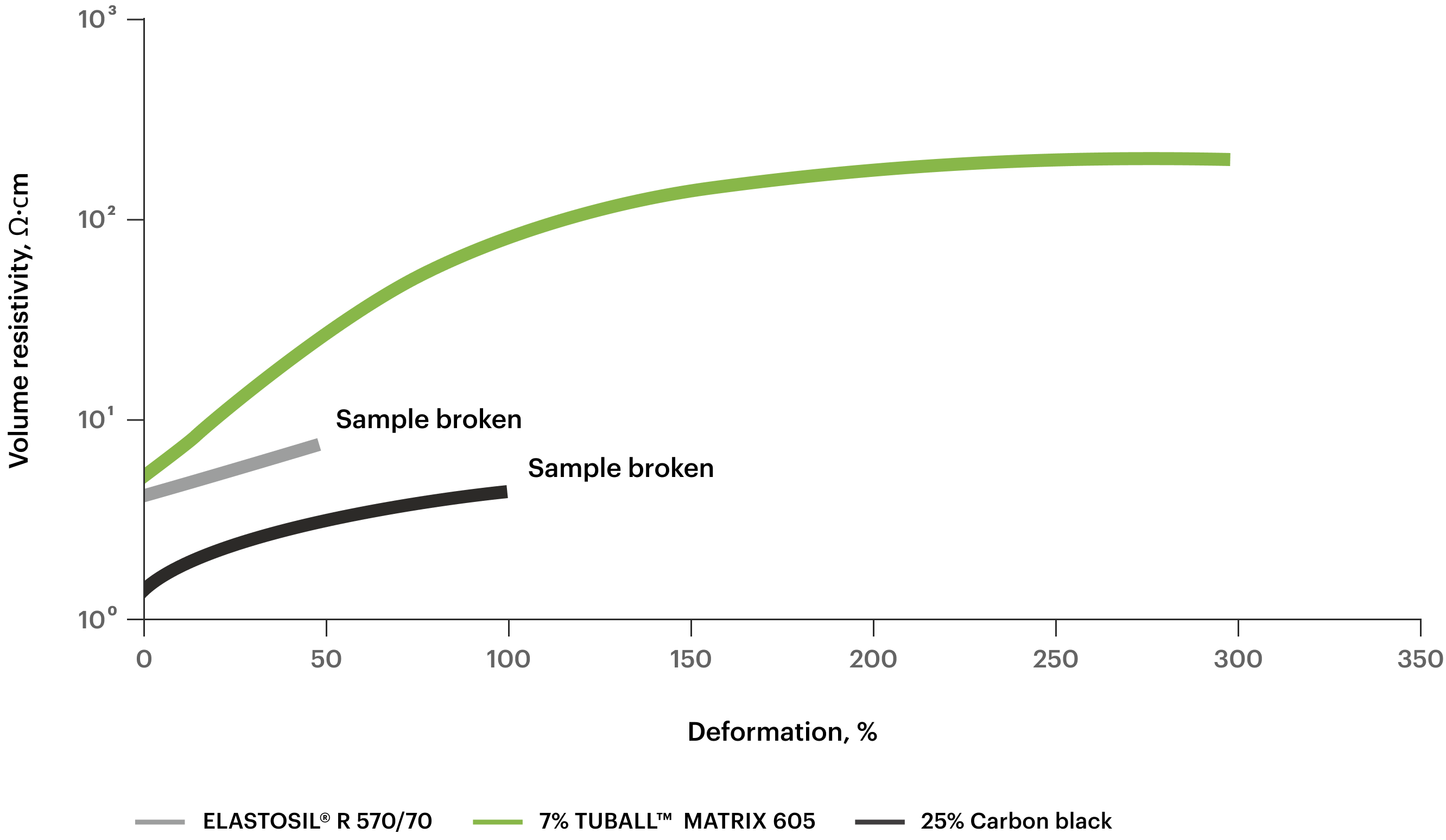

Preserve long-term conductivity under stress. The unique morphology of graphene nanotubes ensures a consistent flexible conductive network throughout the product’s life cycle, regardless of environmental factors, ensuring reliable, high-quality signal transmission.

STABLE CONDUCTIVITY AT HIGH DEFORMATION

CONDUCTIVE HCR: TUBALL™ vs Carbon black

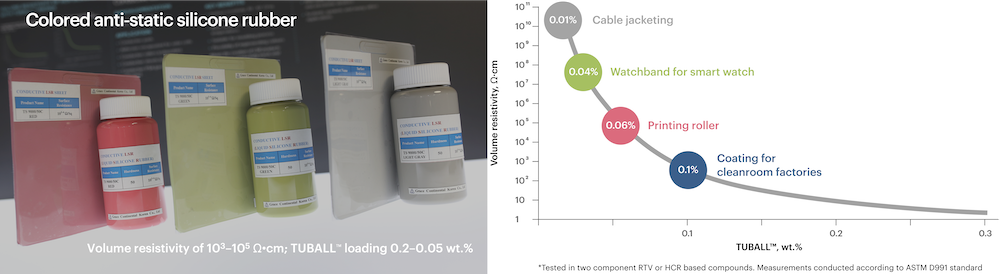

— Enable a wide range of colors with no carbon release on the surface.The unique structure of graphene nanotubes and their ultralow working dosage make it possible to maintain color diversity with no carbon release on the surface.

— Ensure safe skin contact. TUBALL™ nanotubes are fully embedded within the silicone material, eliminating the risk of skin contamination or irritation. The silicone retains its softness and elasticity, ensuring comfort in skin-contact applications. Nanotubes in powder form have passed key toxicological tests related to skin safety, including:

- skin corrosion (OECD 431)

- skin irritation (OECD 439)

- skin sensitization (OECD 406)

- acute dermal toxicity (OECD 402).

— Support clean and efficient processing. Graphene nanotubes are available in TUBALL™ MATRIX 600-series concentrates, based on different carriers for various silicones and pre-dispersed nanotubes. These concentrates are specifically designed for compatibility with standard silicone mixing equipment and processes. They are added during the compounding stage without adding complexity to the manufacturing process. With a recommended working dosage of 0.5–5.0 wt.%, these concentrates ensure excellent dispersion and stable anti-static properties using conventional compounding techniques.

Ultimately, TUBALL™ graphene nanotubes offer a balanced solution for achieving electrical conductivity in silicone rubber. They enable the production of conductive silicone without sacrificing mechanical performance or limiting color options—challenges that persist when using traditional anti-static agents like carbon black, graphite, metal-based fillers, or multi wall carbon nanotubes.

Graphene nanotubes in silicone: case studies and applications

The global conductive silicone rubber market is expected to grow at a CAGR of 8.22% from 2025 to 2030, driven by expanding applications in the electronics, automotive, and other high-tech industries. [1] TUBALL™ graphene nanotubes provide a unique combination of conductivity, elasticity, and color variety at ultralow dosages, enhancing silicone performance without compromising its inherent advantages. Their application is unlocking new possibilities across a wide range of industries:

— Cable accessories. Conductive silicone is critical for electrical connectors and contacts in automotive, aerospace, oil & gas, and packaging. These parts must meet strict conductivity standards to prevent electrostatic discharge. Conventional fillers require high loadings and compromise durability. TUBALL™ nanotubes, even at low concentrations, deliver stable conductivity, support spray coating instead of molding, and enhance mechanical strength and longevity—particularly under extreme conditions.

— Wearable devices. In fitness trackers, smartwatches, and smart textiles, TUBALL™ nanotubes ensure signal transmission and ESD protection at a dosage of just 0.1 wt.%, maintaining softness and skin compatibility. Compared to carbon black or MWCNTs, they provide better tear strength, low viscosity, permanent elasticity, and wide color variety—ideal for vibrant, comfortable wearable electronics.

— Consumer electronics. Protective films for electronics are essential barriers safeguarding smartphones, tablets, and laptops from scratches, fingerprints, and dust. Utilizing graphene nanotubes, such 3C films deliver exceptional functionality, durability, and aesthetic appeal. Nanotubes provide a unique combination of permanent anti-static performance with high transparency in coatings for 3C products, all without any need to alter standard technological processes or equipment.

— Healthcare equipment. Conductive silicone with nanotubes is used in skin-contact medical devices such as electrodes and sensors. These solutions offer stable electrical performance, superior skin comfort, and EU RoHS compliance. The ultralow nanotube dosage maintains elasticity, enabling the creation of clean, non-marking, high-precision monitoring devices.

— Printing components (rollers, plates, pads, profiles). High-speed printing generates static electricity, which can affect print quality and safety, especially when using solvent-based inks. While carbon black limits color choices and alters mechanical properties, TUBALL™ nanotubes provide permanent conductivity without compromising color or structural integrity.

.png)

— Conveyor dampers. In fast-moving production lines, static buildup can damage products or endanger personnel. Nanotube-enhanced silicone preserves RTV softness while delivering ESD protection and producing clean, dust-free, mechanically robust surfaces.

— Personal protective equipment. In environments sensitive to static discharge, anti-static workwear enhanced with graphene nanotubes meets international safety standards, without affecting appearance or manufacturing processes, and supports a wide color range.

— Electronic impulse massage devices. These require both high conductivity and skin-friendly flexibility. Unlike carbon black and metal fibers, TUBALL™ nanotubes enable safe, soft, and clean-contact materials that deliver electrical impulses without surface contamination.

— Touch screen–compatible silicone finger prostheses. The use of TUBALL™ nanotubes in fingertips make affordable touch screen–compatible silicone prosthetic hands possible by conducting electrical signals from the body. The cost of cyber prostheses with such functions is 10 to 15 times lower than that of the nearest comparable solutions.

These are just a few examples of how graphene nanotubes are transforming silicone applications. With their unique ability to combine conductivity, flexibility, durability, and color stability at ultralow dosages, the potential for innovation across industries is far greater.

References:

- “Conductive Silicone Market Size & Share Analysis - Growth Trends & Forecasts (2025–2030),” Mordor Intelligence, https://www.mordorintelligence.com/industry-reports/conductive-silicone-market.

- Shunqi Mei, Jian Wang , Jitao Wan, and Xichun Wu, “Preparation Methods and Properties of CNT/CF/G Carbon-Based Nano-Conductive Silicone Rubber,” Applied Sciences 13, no. 11 (2023): 6726, https://doi.org/10.3390/app13116726.

- Aparna Joshi, Anjali Athawale, “Synthesis and Characterization of Electrically Conductive Silicone Rubber—TiB2 composites,” Characterization and Application of Nanomaterials 2, no. 2 (2019), https://systems.enpress-publisher.com/index.php/CAN/article/view/644/0.

- Lijuan Lei, Peng Guo, Xingzhi Shi, and Zhehui Li, “Conductive Liquid Silicone Rubber and Preparation Method and Use Thereof,” https://patents.justia.com/patent/20210253857.

- Elnaz Esmizadeh, Mostafa Arjmandpour, and Charles Dubois, “Preparation and Characterization of Silicone Rubber/Graphene Nanosheets Nanocomposites by In-situ Loading of the Coupling Agent,” Journal of Composite Materials 53, no. 24 (2019): 3459–3468; https://doi.org/10.1177/0021998319840799.

- Yuanhang Yang, Shun Duan, and Hong Zhao, “Highly Conductive Silicone Elastomers via Environment-Friendly Swelling and In Situ Synthesis of Silver Nanoparticles,” Advanced Materials Interfaces 8, no. 9 (2021), https://doi.org/10.1002/admi.202100137.

- Man Xiong, Xuan Bie, Ben Wang, Yawei Dong, Qunchao Zhang, and Ronghua Huang, “Preparation and Properties of Conductive Foamed Silicone Rubber,” Wuhan University Journal of Natural Sciences 27, no.1 (2022): 57–62, https://doi.org/10.1051/wujns/2022271057.

- Haruki Wakita, Koji Shimizu, and Mitsuo Hamada, “Method of Preparing a Conductive Silicone Rubber Particulate,” https://patents.google.com/patent/US5085803A/en.

- Anjum Saleem, Lars Frormann, and Alexandru Soever, “Fabrication of Extrinsically Conductive Silicone Rubbers with High Elasticity and Analysis of Their Mechanical and Electrical Characteristics,” Polymers2, No. 3 (2010): 200–210, https://doi.org/10.3390/polym2030200.

- Hai-Tao Deng, Dan-Liang Wen, Tao Feng, Yi-Lin Wang, Xin-Ran Zhang, Peng Huang, and Xiao-Sheng Zhang, “Silicone Rubber Based-Conductive Composites for Stretchable ‘All-in-One’ Microsystems,” ACS Applied Materials & Interfaces 14, no. 35 (2022), https://pubs.acs.org/doi/abs/10.1021/acsami.2c08333.

- Shunqi Mei, Jian Wang, Jitao Wan, and Xichun Wu, “Preparation Methods and Properties of CNT/CF/G Carbon-Based Nano-Conductive Silicone Rubber,” Applied Sciences 13, no. 11 (2023): 6726, https://doi.org/10.3390/app13116726.

- Tae Ann Kim, Hee Suk Kim, Sang Soo Lee, and Min Park, “Single-Walled Carbon Nanotube/Silicone Rubber Composites for Compliant Electrodes,” Carbon 50, no. 2 (2012): 444–449, https://doi.org/10.1016/j.carbon.2011.08.070.