Graphene nanotubes for anti-static textile coatings: ESD safety in compliance with international standards

TUBALL™ nanotubes are a unique anti-static agent that provides electrical conductivity at low dosages not achievable with any standard conductive additive. Textiles with improved electrical conductivity are used to avoid the hazards of electrostatic discharge (ESD) and can achieve the anti-static performance required by safety regulations.

TUBALL™ graphene nanotubes are available in various forms depending on the industrial application: the easy-to-use additive TUBALL™ MATRIX, which is a line concentrates based on polymer carriers and pre-dispersed TUBALL™ graphene nanotubes, and TUBALL™-based liquid-phase suspensions with properly dispersed and stabilized graphene nanotubes.

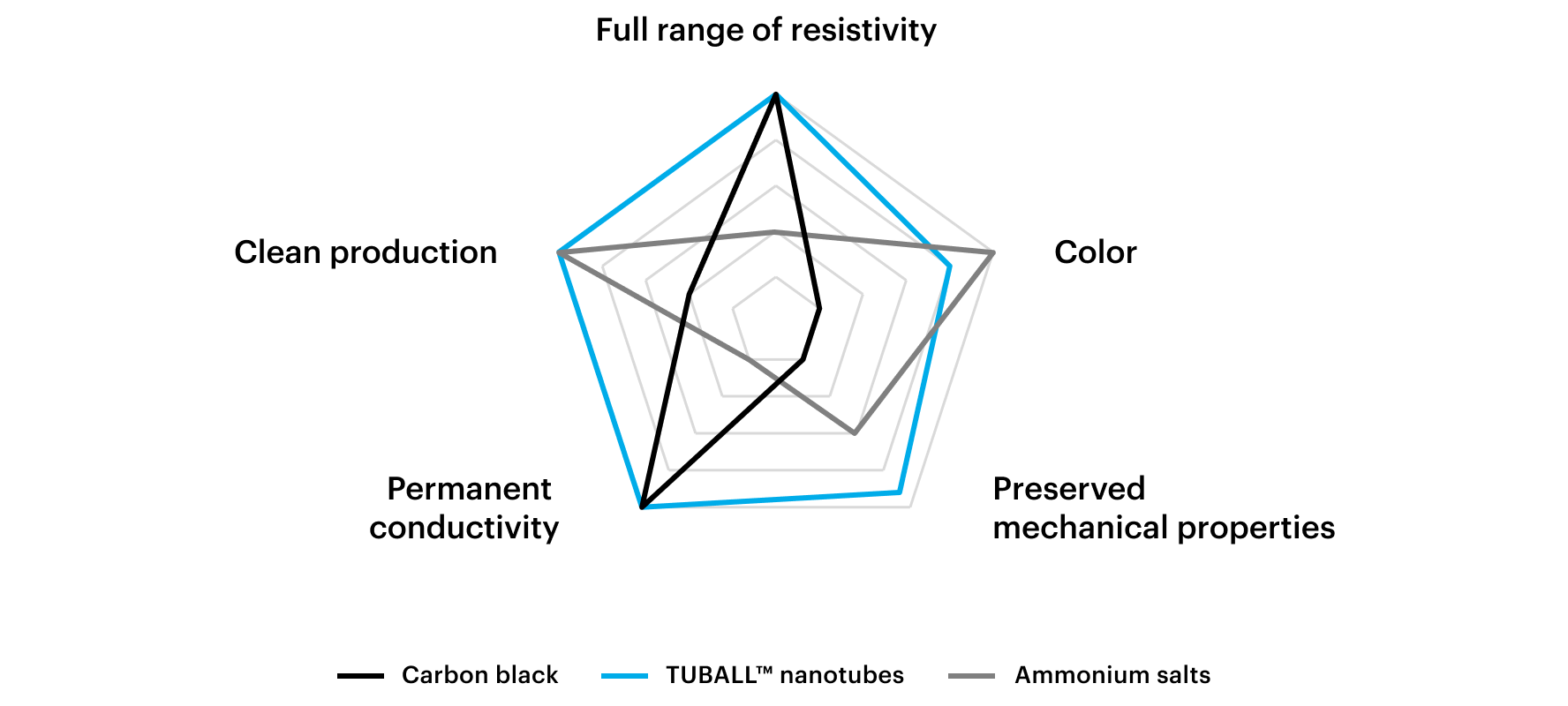

TUBALL™ graphene nanotubes: Good performance on all key parameters

In contrast to other conductive agents, TUBALL™ graphene nanotubes are a versatile conductive agent offering good performance on all key parameters.

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

| Parameter | Ammonium compounds | Carbon black | TUBALL™ nanotubes |

|---|---|---|---|

| Working dosage, wt.% | 0.2–4.0 | 4–12 | 0.01–0.1 |

| Surface resistivity range, Ω/sq | 108–1011 | 103–1011 | 103–1011 |

Influence on mechanical performance |

small negative | strong negative | none |

| Influence on rheology | none | strong negative | comparable |

| Color opportunity | yes | none | yes |

| Dust formation during production | none | high | none |

| Resistivity independent of humidity | no | yes | yes |

| Stable resistivity over time | no | yes | yes |

Key benefit 1: Compliance with industrial safety regulation

There is a number of standards related to regulations for ESD protection in safety wear. Graphene nanotubes can be used to achieve all these requirements.

- EN ISO 18080, EN 1149, EN 61340, EN 16350, ANSI/ESD STM2.1, Directive 1994/9/EC and ATEX Directive 95, GOST 19616, GOST 12.4.124 and others

- Depending on the relevant standard, the textile type and the final application, generally, the resistance needs to be in the range of 105–1011 Ω

Applications: oil and gas, chemical facilities, pharmaceutical and medical areas, electronics manufacturing, automotive industry, etc.

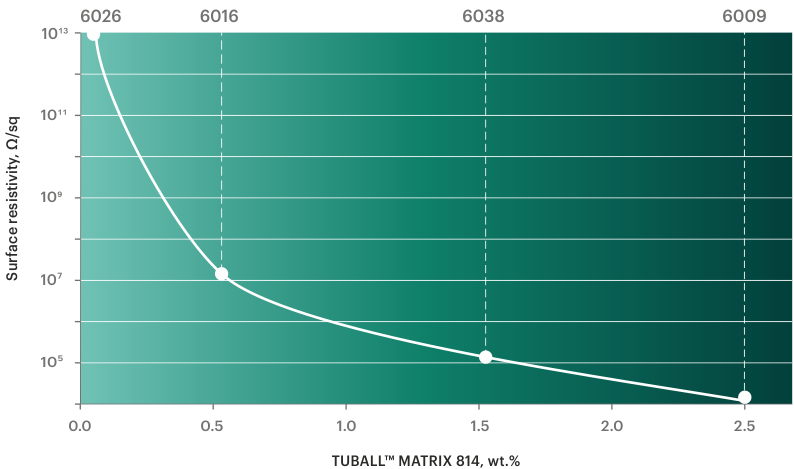

Key benefit 2: Colored anti-static compounds

The extremely low dosage required of graphene nanotubes creates the opportunity to produce colorful solutions where desired.

0.25–1.5 wt.% of TUBALL™ MATRIX 814 for 105-109 Ω/sq with maintained color. OCSiAl internal PVC-plastisol formulation. Sample thickness: 2 mm. ASTM D257

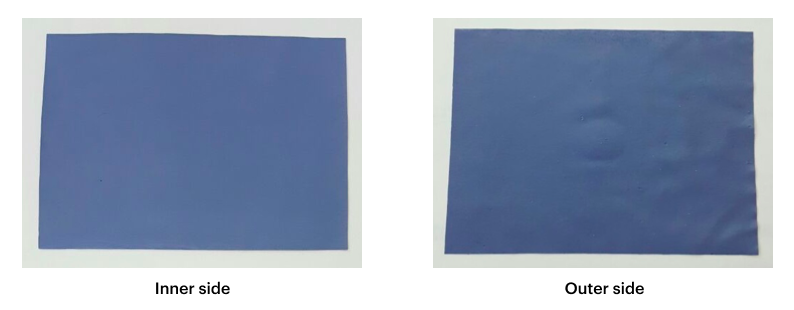

Colored anti-static nitrile film with 0.06 wt.% of TUBALL™

Surface resistivity of 107 Ω/sq

Key benefit 3: Standard processing and mixing equipment

TUBALL™-based products can be processed with standard equipment widely used by textile manufacturers.

Other benefits

- No carbon release on surface

- Permanent and stable level of resistivity

- No negative influence on mechanical properties

- Minimally affects density, viscosity and other rheological properties of formulations

- Resistivity is independent of humidity

TUBALL™ MATRIX for silicone coatings (LSR, RTV)

TUBALL™ LATEX for NBR, NR, PU Latexes

Application cases

Silicone Textile Coating

Latex Textile Coating

PVC Plastisol-based Textile

Please pay close attention to processing guidelines

Download PDF version:

Or watch video instruction:

TUBALL™ LATEX - Processing Guidelines

TUBALL™ MATRIX - Processing guidelines

Additional resources:

ESD Colored Latex Gloves - New Standard

Electrical resistivity guidelines

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample