Graphene nanotubes for colored rollers and conveyor belts: combining color and long service life

TUBALL™ nanotubes provide stable anti-static performance to elastomer compounds made of silicone, rubber and PU while retaining mechanical properties and minimally impacting the host matrix.

TUBALL™ graphene nanotubes are applied via the easy-to-use additive TUBALL™ MATRIX, which is a line of concentrates based on polymer and plasticizer carriers and pre-dispersed TUBALL™ graphene nanotubes.

TUBALL™ graphene nanotubes: good performance on all key parameters

In contrast to other conductive agents, TUBALL™ graphene nanotubes are a versatile conductive agent offering good performance on all key parameters.

Technical and commercial benefits in silicone compounds

|

Parameter |

Carbon black |

MWCNT |

|

|

Working dosage |

10 wt.% |

1–3 wt.% |

1–2 wt.% |

|

Resistance requirements (Volume Resistivity) |

105–107 Ω•сm |

||

|

Resistance result |

106–109 Ω•сm |

105–107 Ω•сm |

105–107 Ω•сm |

|

Black dots on surface |

only black available |

only black available |

none |

|

Available color range |

none |

none |

wide |

|

Resistance remains stable after abrasion on surface |

no |

yes |

yes |

|

Influence on mechanical performance |

strong negative |

strong negative |

none |

|

Influence to rheology |

strong negative* |

strong negative* |

none |

|

Dust formation during production |

yes |

yes/none |

none |

|

‘Hot spots’ |

yes |

possible |

none |

|

Stable resistance over time |

no |

yes |

yes |

|

Longer life cycle of compound and molded parts |

no |

no |

yes |

|

Carbon release on surface |

yes |

none |

none |

|

Cost of anti-static property |

comparable |

comparable |

comparable |

* Formulation design required (adjustment of curing system)

Key benefit 1: Colored anti-static compounds

The wide range of color options makes it possible to provide various parts to the market where anti-static properties are required.

Silicones

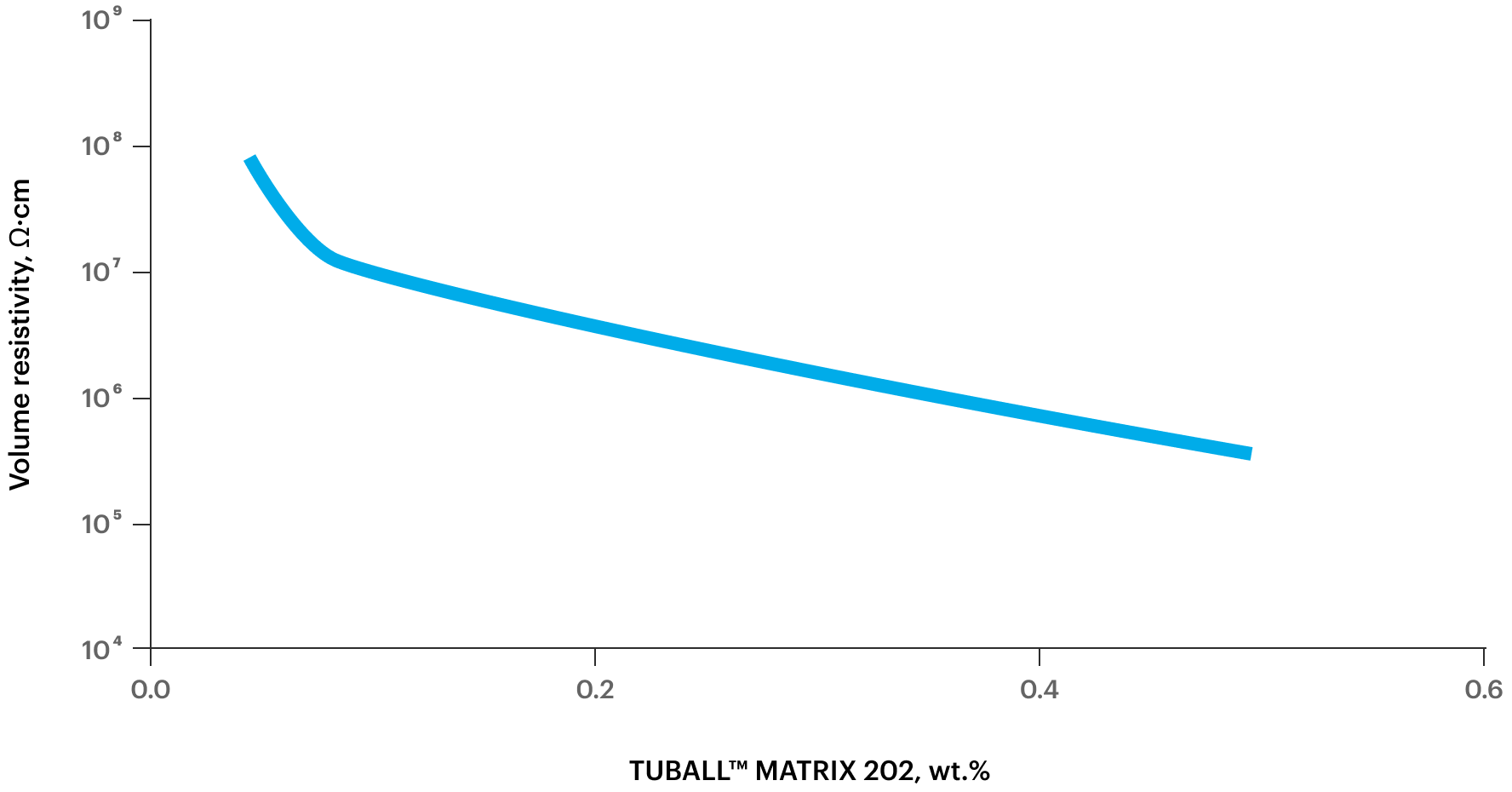

Volume resistivity of 103–105 Ω•cm. TUBALL™ loading 0.2–0.05%

Polyurethanes

OCSiAl internal PU formulation. ASTM D257

Key benefit 2: Maintained mechanical and anti-static properties

TUBALL™ nanotubes, in contrast to traditional conductive agents, minimize the impact on compound elasticity and tensile parameters, viscosity and rheological properties.

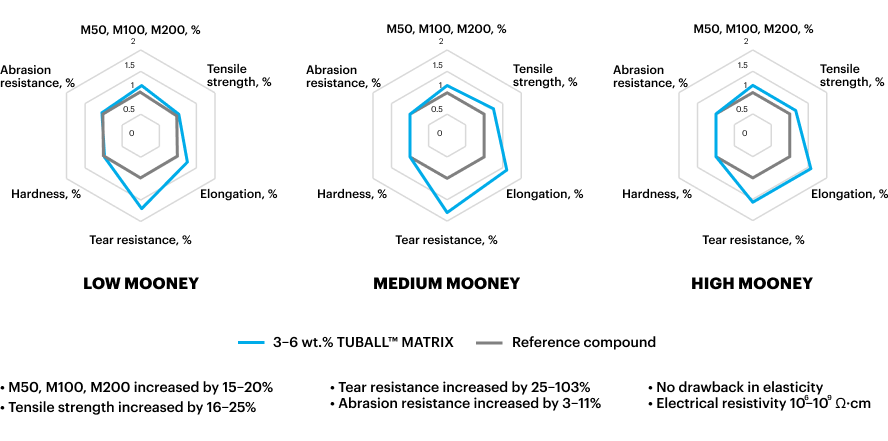

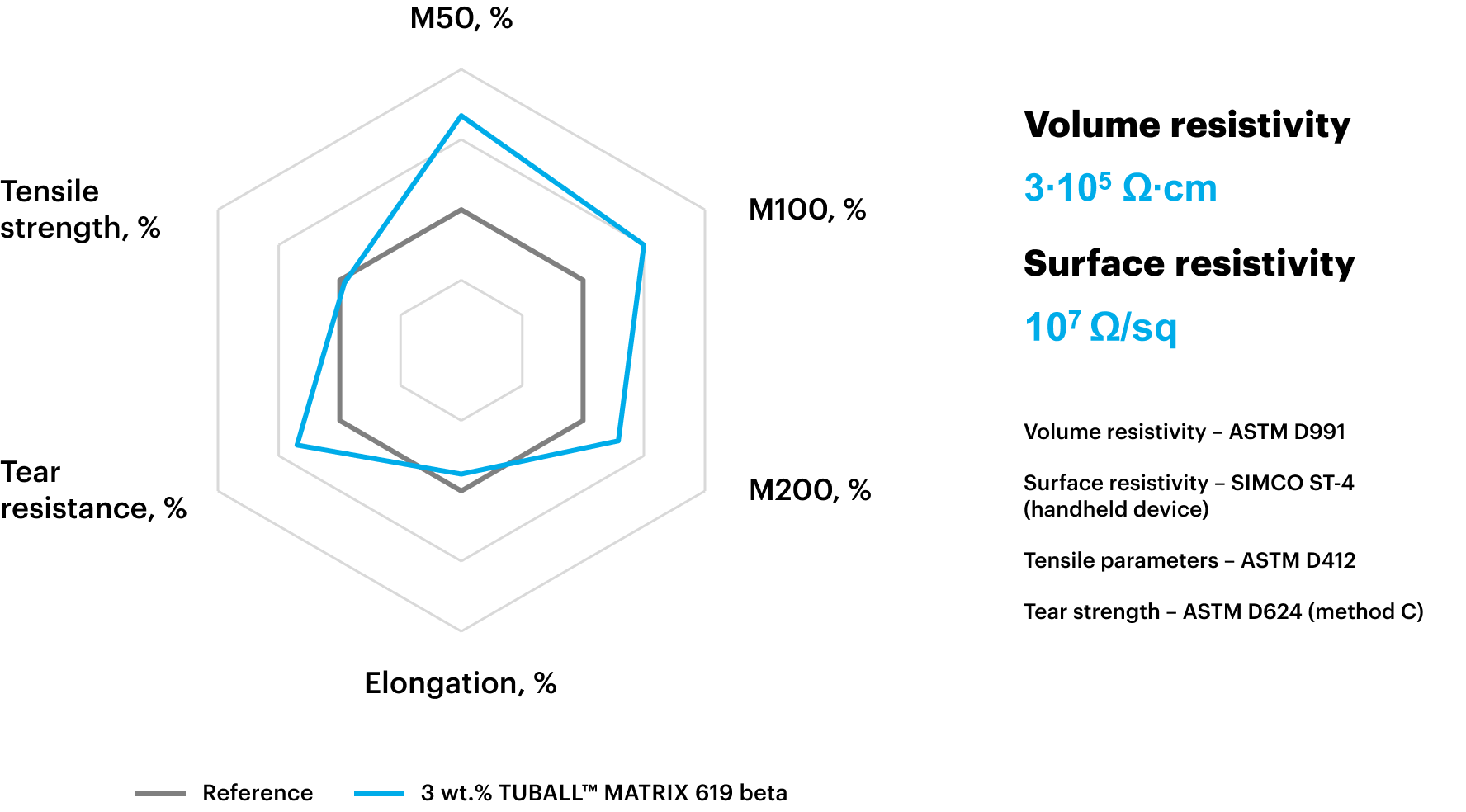

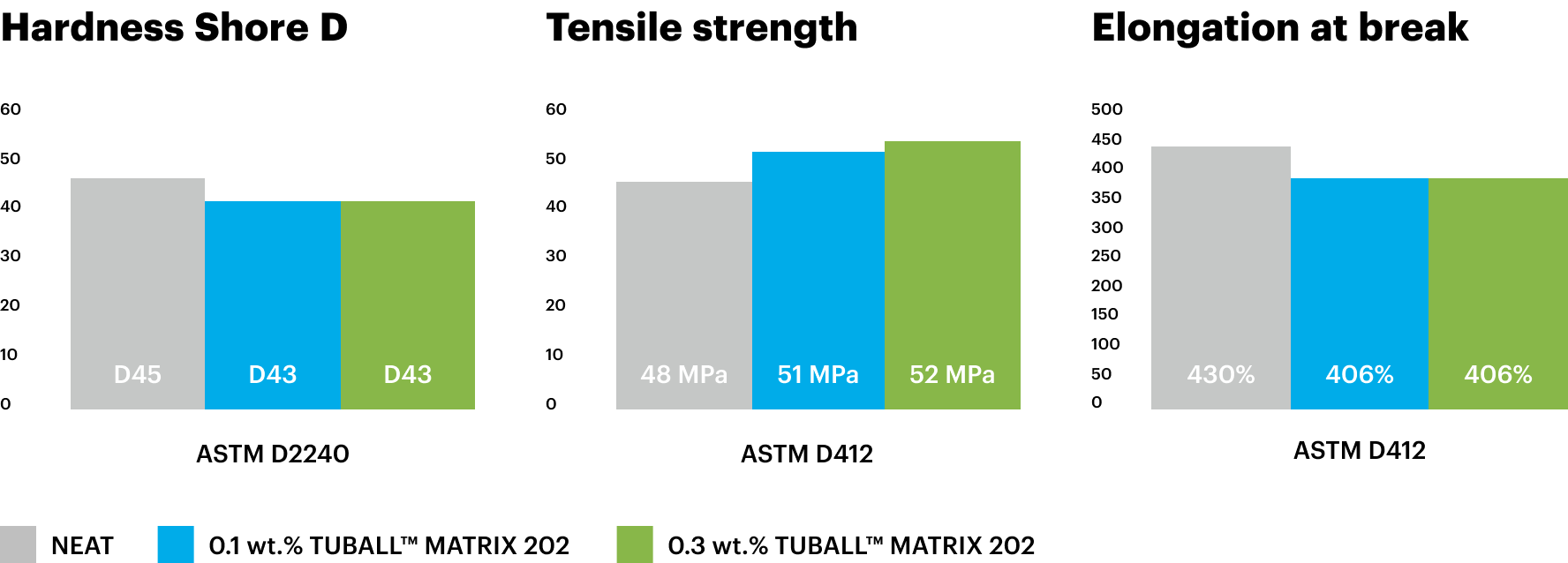

Test results in various formulations: Mechanical properties

The extra-low dosage of TUBALL™ required in silica-based EPDM and NBR formulations allow the desired anti-static properties as well as improvements in tear strength and tensile performance to be achieved without degradation of elastic properties and hardness.

EPDM

NBR

PU

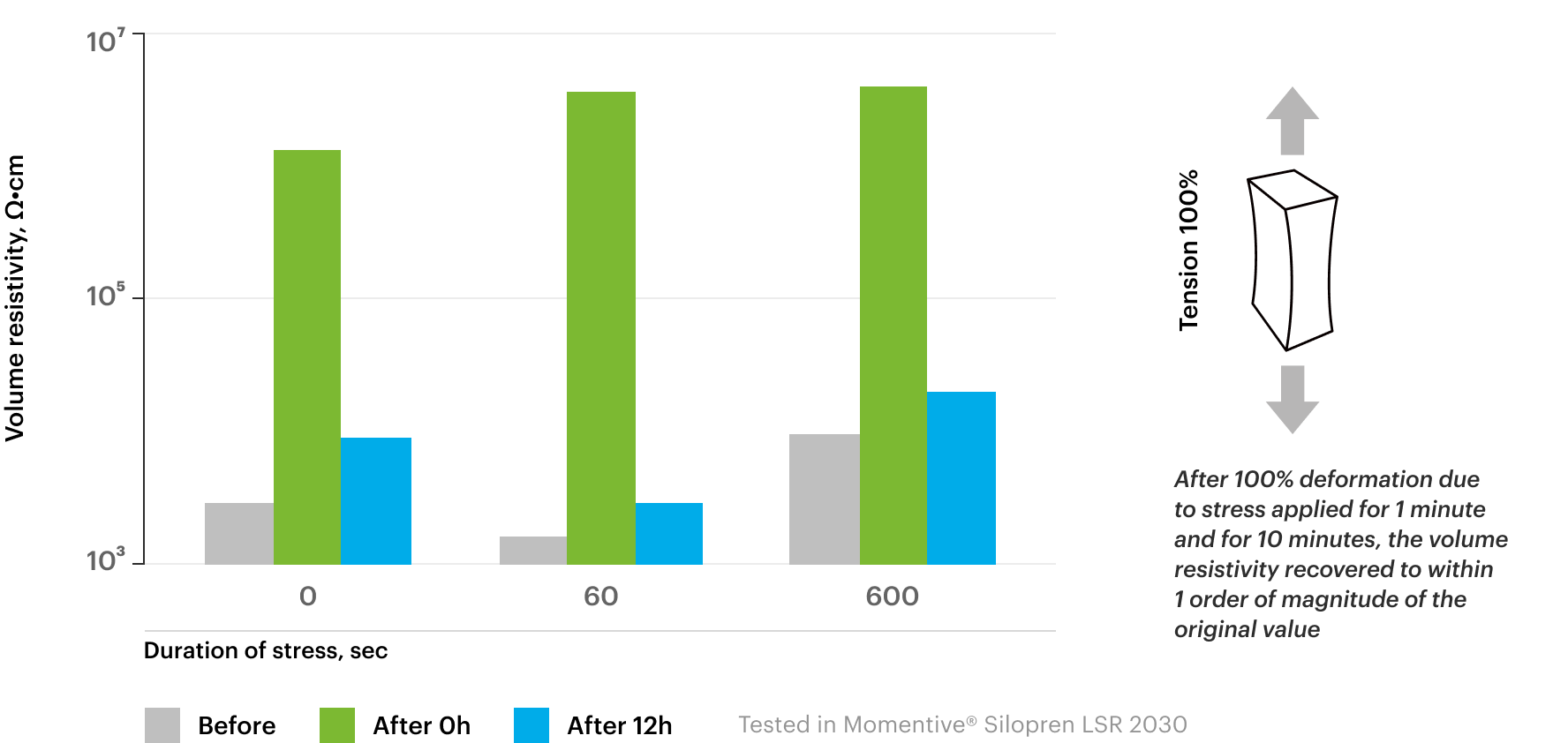

If it is necessary to use materials under conditions of deformation, it is important to maintain stable resistivity. Using TUBALL™ MATRIX, the resistivity is maintained within the target value after dynamic loads.

High dynamic pressure applications – anti-static LSR with 1 wt.% of TUBALL™ MATRIX 601

Key benefit 3: no carbon release, non-marking compounds

When using carbon black, due to its high concentration (10% and more) and because of the spherical shape of the particles, a phenomenon is known in the industry as “carbon release” takes place, when the conductive additive is present on the surface of the sample.

In contrast, graphene nanotubes, owing to their greater length-to-diameter ratio, are not released to the surface.

Key benefit 4: standard processing and mixing equipment

TUBALL™ MATRIX has to be processed with standard equipment broadly used by rubber roller manufacturers.

Other benefits

- Extremely low loadings of TUBALL™ that preserve properties

- Ensure permanent and uniform electrical conductivity without “hot spots”

- Maintain rheology of the uncured compound

- Maintained softness and elastic properties

Download PDF version:

Please pay attention to processing guidelines for TUBALL™ MATRIX

Or watch video instructions:

Conductive colored HCR: Processing guidelines for TUBALL™ MATRIX 605

Anti-static colored EPDM rubbers - Processing guidelines

Application cases

NBR conveyor belts and rollers

Industrial Conveyor Belts

Mining Rollers

Additional resources:

Conductive Silicones - LSR, RTV, HCR and PSA

Conductive elastomers: Prevent negative trade-offs in mechanical properties and color due to SWCNT

A new era?

OCSiAl Introduces New TUBALL MATRIX Products for Elastomers

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample