Graphene nanotubes for ESD floors: targeted conductivity with flexibility in floor thickness and preserved color

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of additives based on polymer-carriers and pre-dispersed TUBALL™ graphene nanotubes.

Choose the TUBALL™ MATRIX product based on the carrier medium that suits your formulation:

|

Target system |

Solvent-free |

Solvent-based |

||||

|

Epoxy and polyurethane |

Epoxy and polyurethane |

|||||

|

Additive carrier |

Plasticizer |

Surfactant |

Plasticizer |

Plasticizer + stabilizing agent |

||

Fatty acid glycidyl ester |

Alkyl glycidyl ether |

Ethoxylated alcohol |

Fatty carboxylic acid ester derivatives |

Fatty acid glycidyl ester + ammonium salt of a polyolefin-based derivative |

Alkyl glycidyl ether + ammonium salt of a polyolefin-based derivative |

|

|

Product |

|

|

|

|

|

|

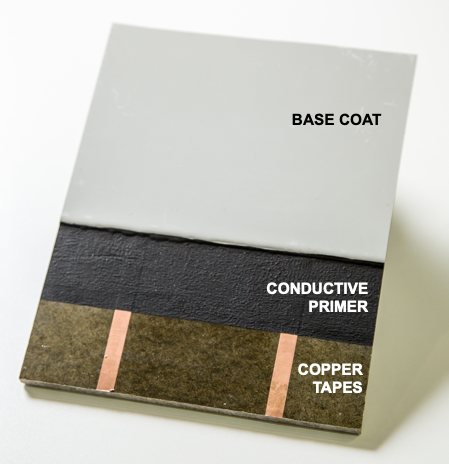

How anti-static flooring works

Any accumulated electrical charges should be conducted from the surface to ground.

Requirements example

Surface-to-ground resistance:

- dissipative range: 106–109 Ω

- conductive range: 2.5⋅104–106 Ω

According to ASTM F150. Some flooring systems can also include an additional thin topcoat.

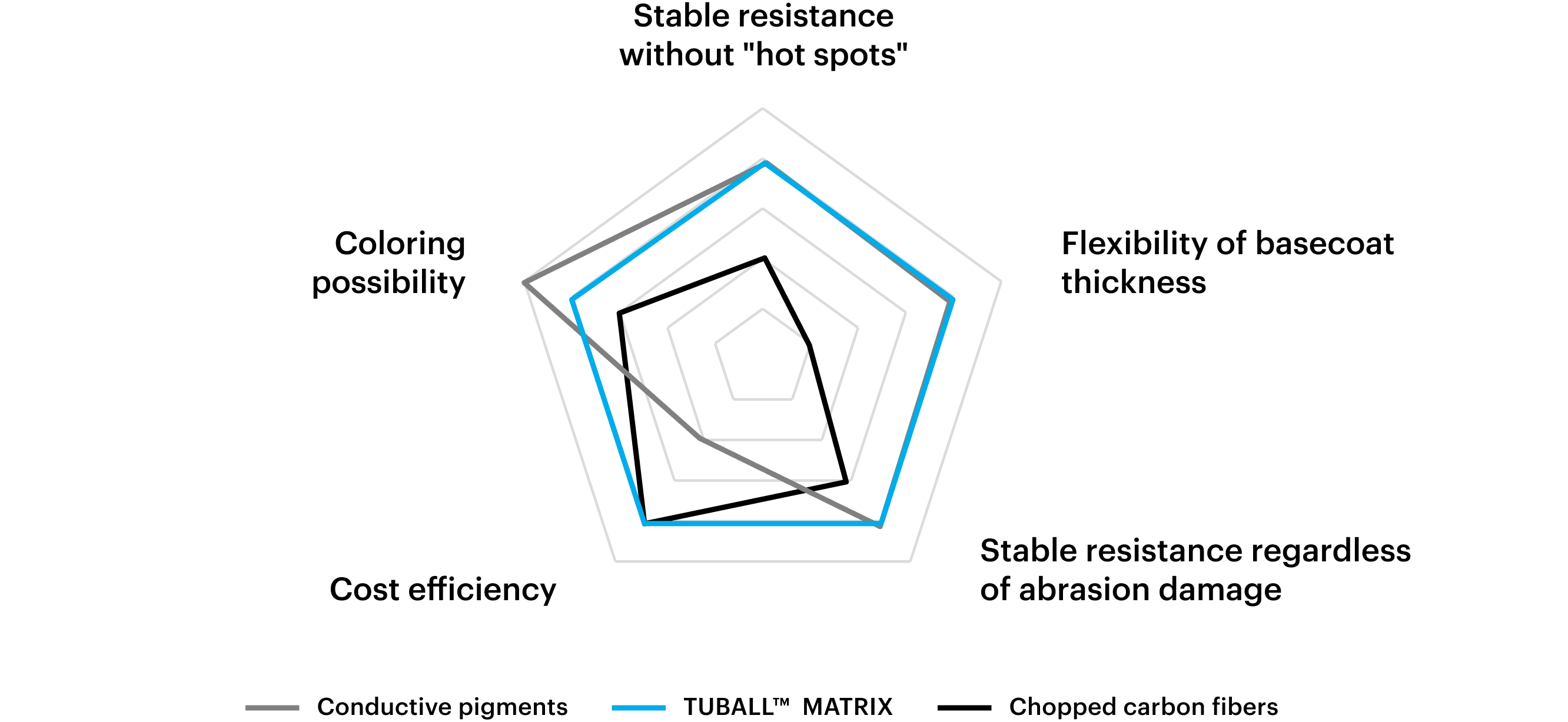

TUBALL™ graphene nanotubes are a versatile conductive agent offering strong performance on all key parameters

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

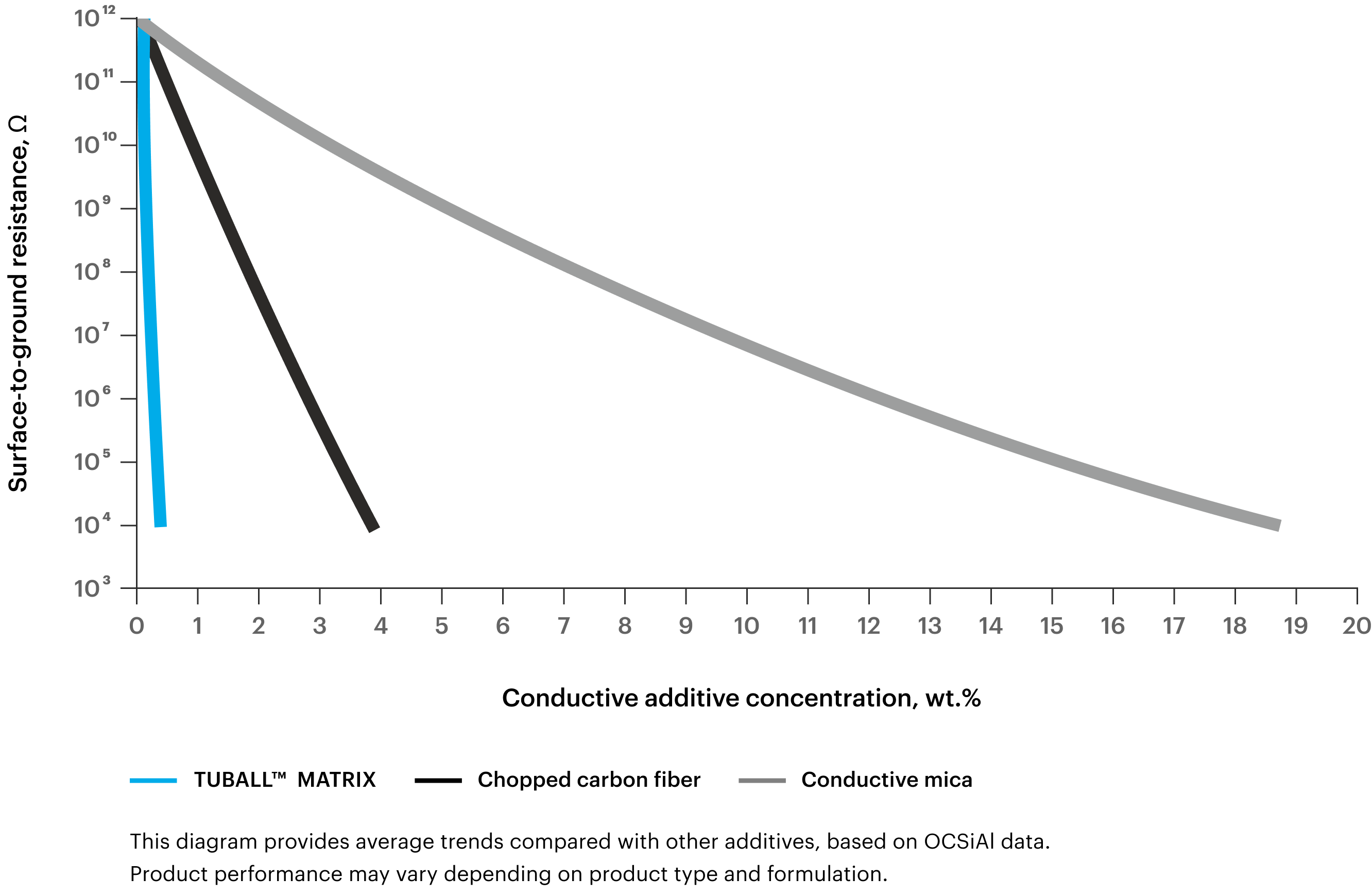

Low working dosages and flexibility in basecoat thickness

Compared with chopped carbon fiber and conductive mica, TUBALL™ nanotubes allow the required conductivity to be obtained at much lower working dosages.

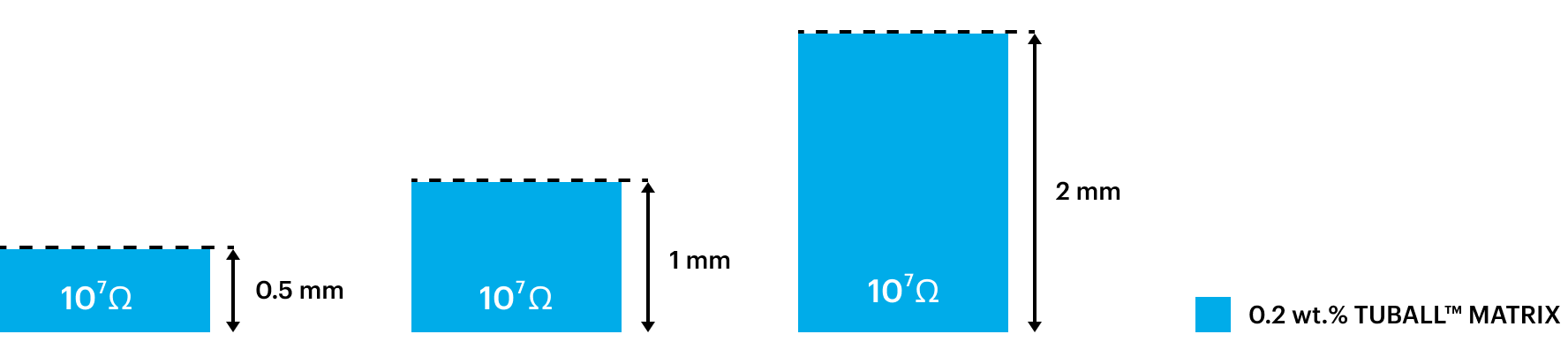

Surface-to-ground resistance at different base coat thickness

Because of the length of chopped carbon fiber (2 mm or longer), the thickness of the base layer must be at least as much (~2 mm). This can result in difficulties in the installation process, increased costs, and the possibility of there being insulating “hot spots”. In contrast, TUBALL™ can be used with various anti-static flooring systems and thicknesses.

Conductive mica has the highest price per property, which is a result of the initial high price of this ESD additive combined with the high working dosage required, which is ~ 5–20 wt.%.

Product performance may vary depending on product type and formulation.

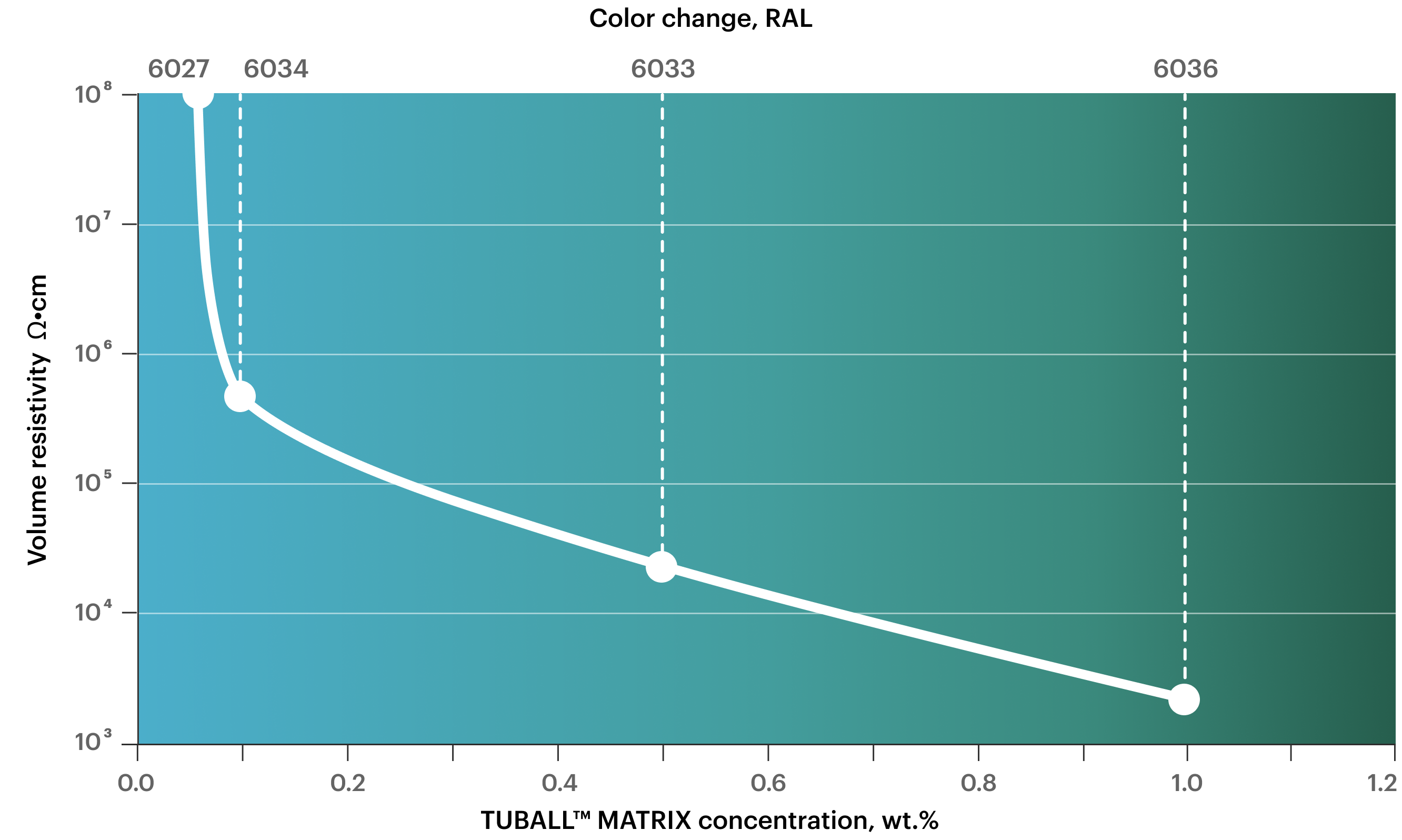

Full range of electrical resistivity with variety of color options

Results for epoxy resin D.E.R. 351.

Easy to apply

TUBALL™ MATRIX can be processed with standard equipment that is widely used in the coatings industry.

Standard single-shaft high-speed mixer

25 min total dilution time

Instant quality control with a grindometer to reach particle size ≤ 15 µm

Other benefits provided by TUBALL™ nanotubes for static dissipative flooring:

- Floors with TUBALL™ nanotubes can be used without conductive primer

- Low dosage gives greater flexibility in the final formulation

- Easy to apply and the low dosage makes the logistics less complex and more efficient

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™-based products.

TUBALL™ MATRIX for solvent-free epoxy and polyurethane

TUBALL™ MATRIX for solvent-free polyurethane

TUBALL™ MATRIX for solvent-based epoxy and polyurethane

Application cases

Epoxy Floor

Pay close attention to the processing guidelines for TUBALL™ MATRIX 200-x and 300-x series

Download PDF version:

Or watch the processing guidelines video:

TUBALL™ MATRIX — Processing guidelines

Additional information

3 reasons to choose graphene nanotubes for self-leveling anti-static floors

How to optimize formulation with TUBALL™ MATRIX (4 min)

TUBALL™ graphene nanotubes (single-walled carbon nanotubes) can be used in the production of conductive and static dissipative systems for floor coverings in accordance with the following standards and recommendations: IEC 61340-4-1: 2017, ASTM F150-06 (2018), ANSI / ESD S20.20, etc

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample.