Versatile conductive additive based on a plasticizer with a stabilizing agent for polyester and vinyl-ester coatings, for melamine and acrylic solvent-based applications. Also recommended for polyester and vinyl-ester composites.

To buy nanotube products, please contact us. Price depends on the required volumes.

Benefits

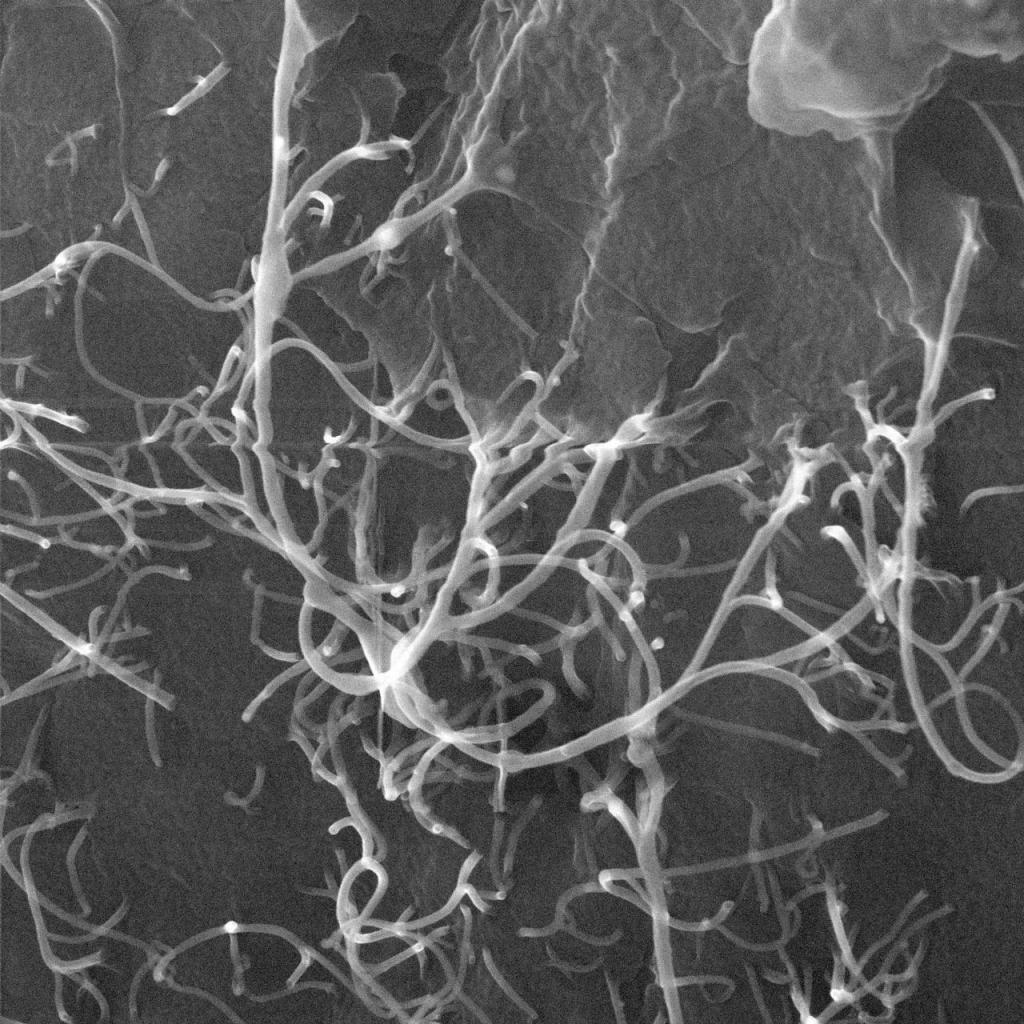

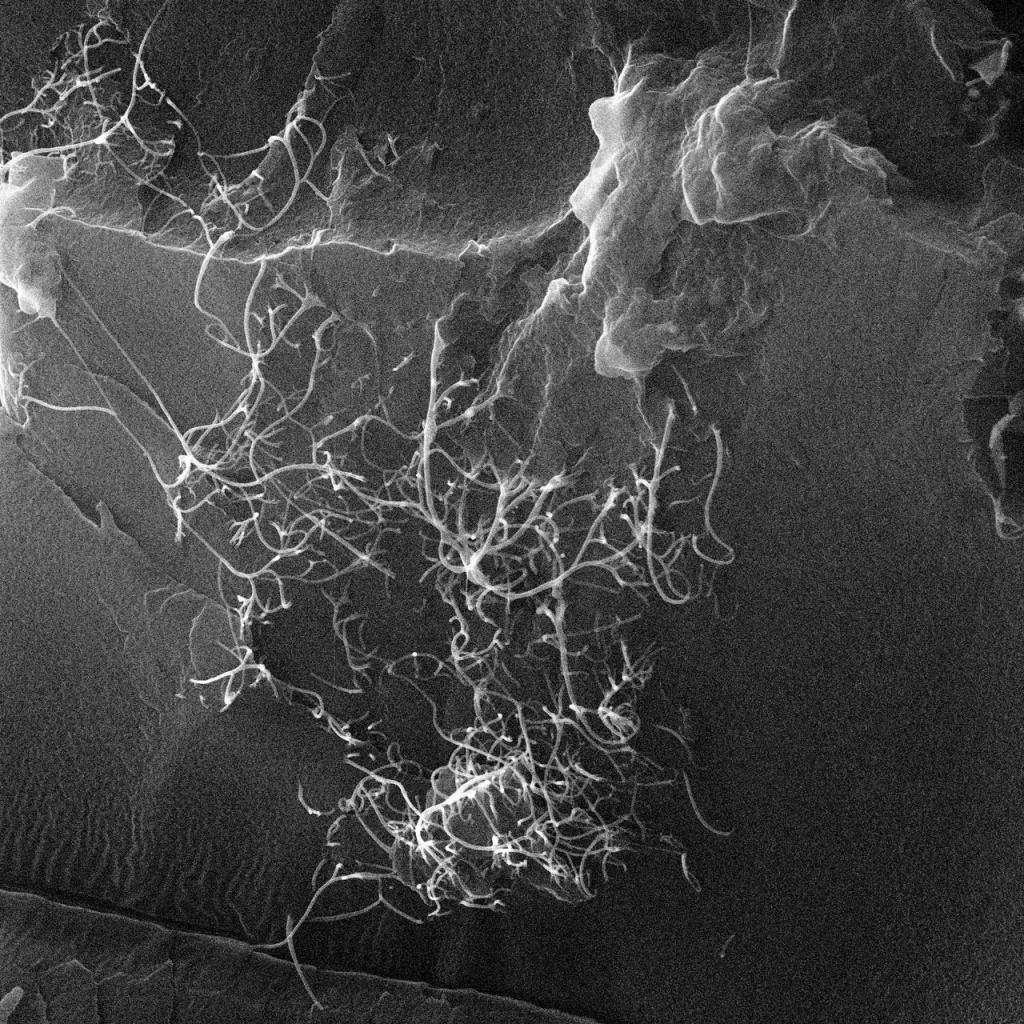

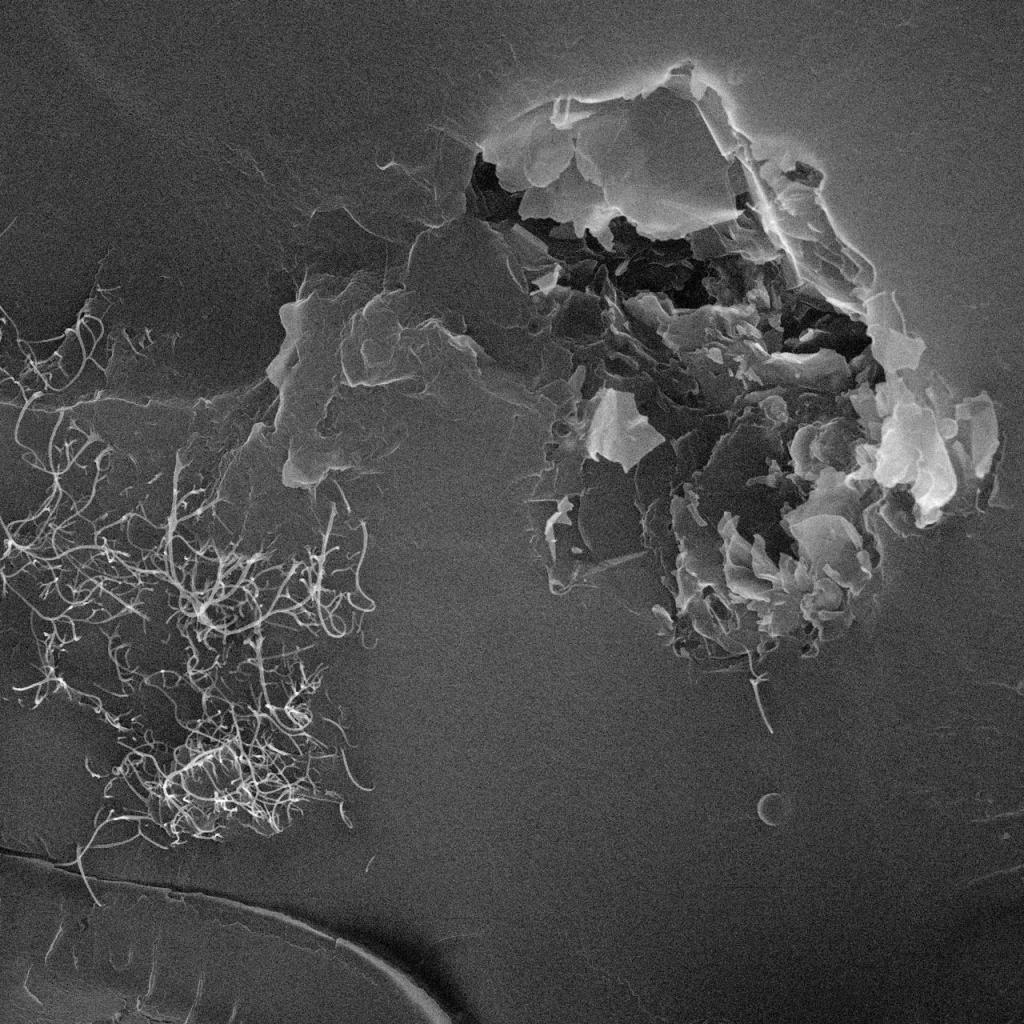

Allows uniform and permanent electrical conductivity without “hot spots”

Anti-static properties independent of humidity

Maintains or even increases mechanical properties

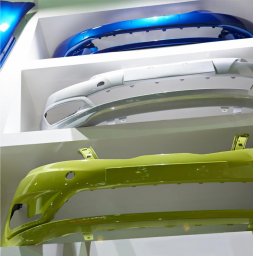

Adding color to polyester, vinyl ester, melamine and acrylic systems is possible due to low working dosages of the concentrate and minimal greying effect

Minimally affects density, viscosity and other rheological properties of matrix material

The pre-dispersed formula allows use of standard manufacturing equipment

Cases

Anti-static gelcoats for children's slides

Conductive Solvent-based Acrylic Primer

Fiberglass reinforced grantings

Video

TUBALL MATRIX — Processing Guidelines

Conductive automotive primers with TUBALL™ MATRIX - Processing guide