Graphene nanotubes for thermoset fiberglass composites: conductivity with maintained color and durability

TUBALL™ graphene nanotubes are applied via easy-to-use TUBALL™ MATRIX, which is a line of additives based on polymer-carriers and pre-dispersed TUBALL™ graphene nanotubes.

Choose the TUBALL™ MATRIX product based on the carrier medium that suits your formulation:

| Target system |

Vinyl ester and polyester |

|

| Additive carrier |

Plasticizer + stabilizing agent |

Surfactant |

|

Triethylene glycol dimethacrylate + ammonium salt of polyolefin-based derivatives |

Ethoxylated alcohol |

|

Product |

|

|

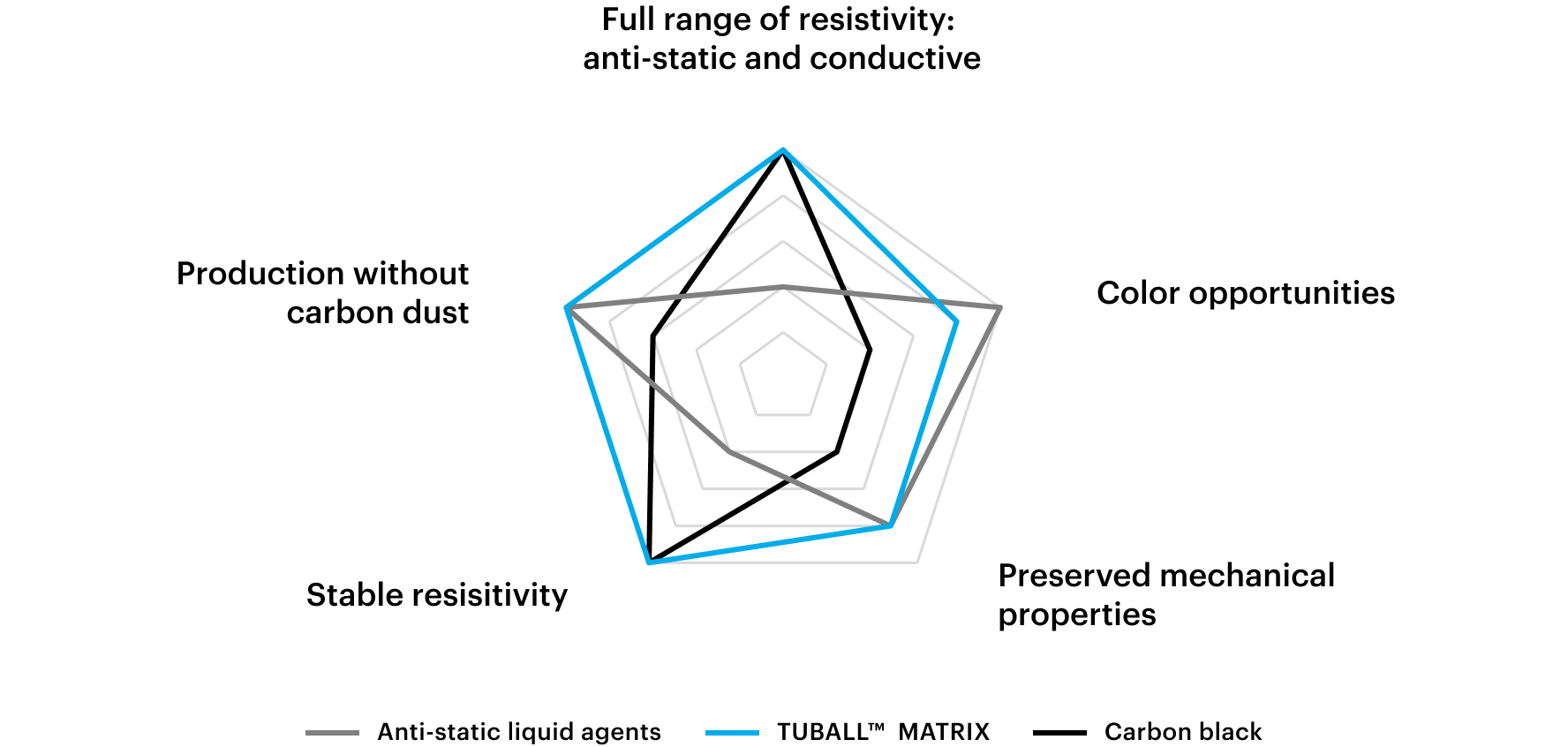

Increased performance of anti-static and conductive thermoset fiberglass composites

Note: this diagram provides average trends compared with other additives, based on OCSiAl data. Product performance may vary depending on product type and formulation.

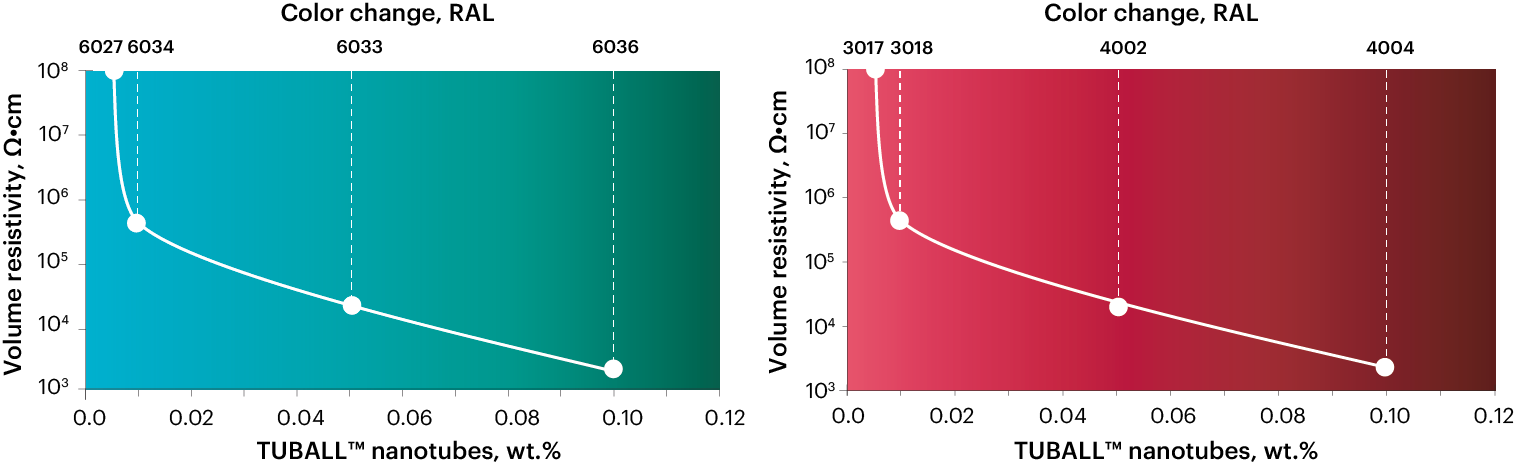

Full range of resistivity while preserving color

Results for epoxy resin D.E.R. 351. Samples include 5 wt.% of TiO2 as a whitening agent. ASTM D257

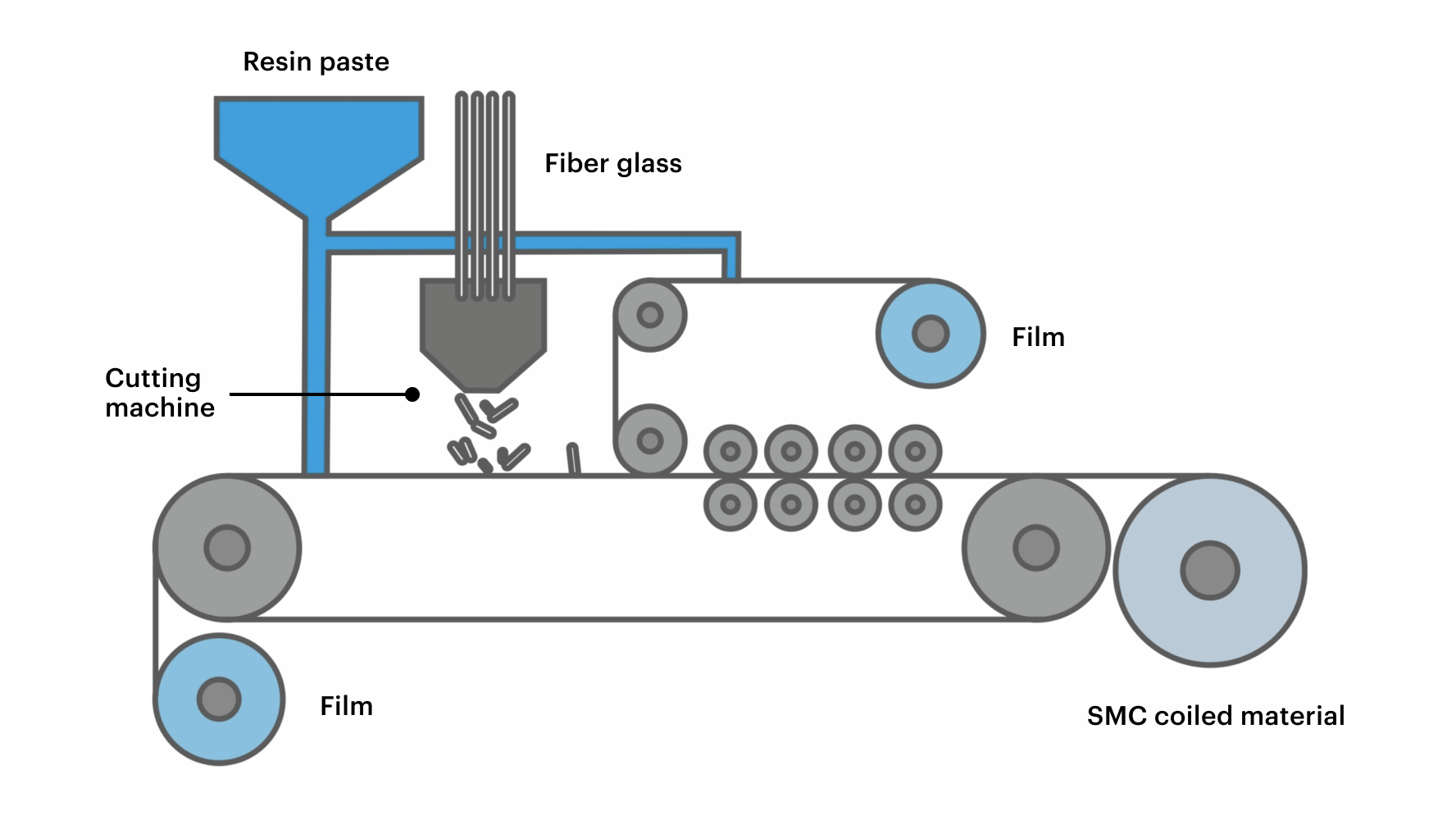

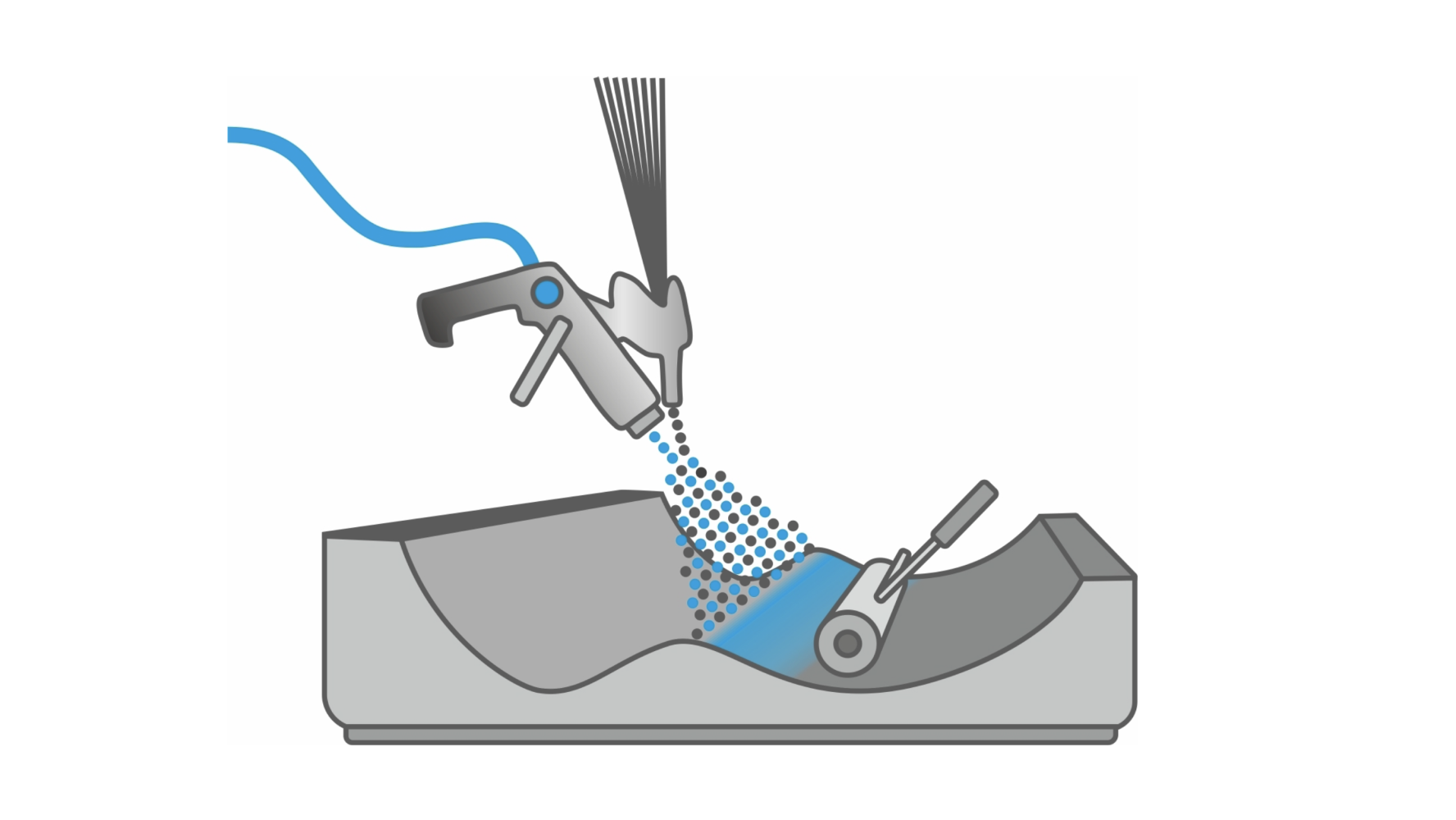

Compatible with key manufacturing technologies

SMC/BMC |

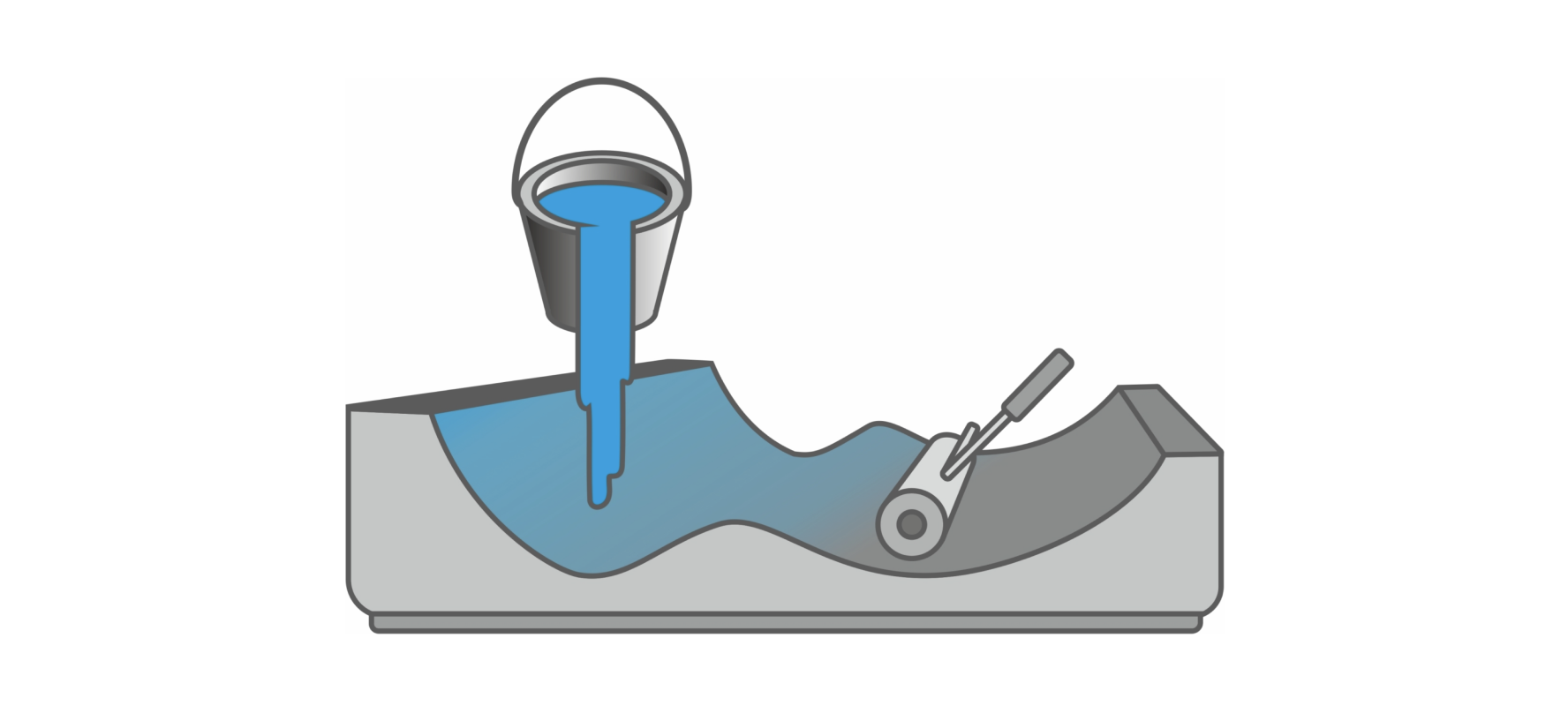

Spray-up |

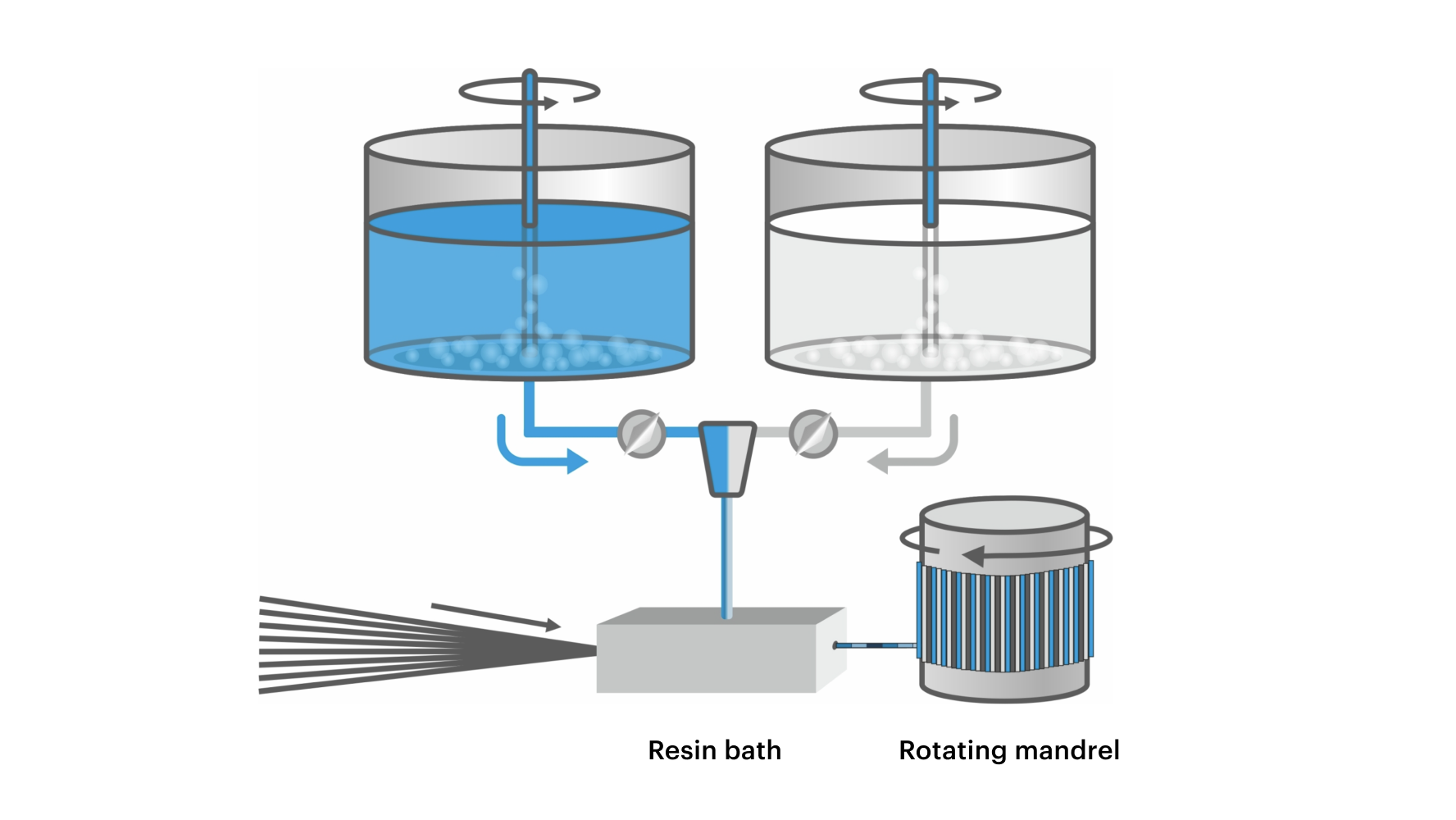

Filament winding |

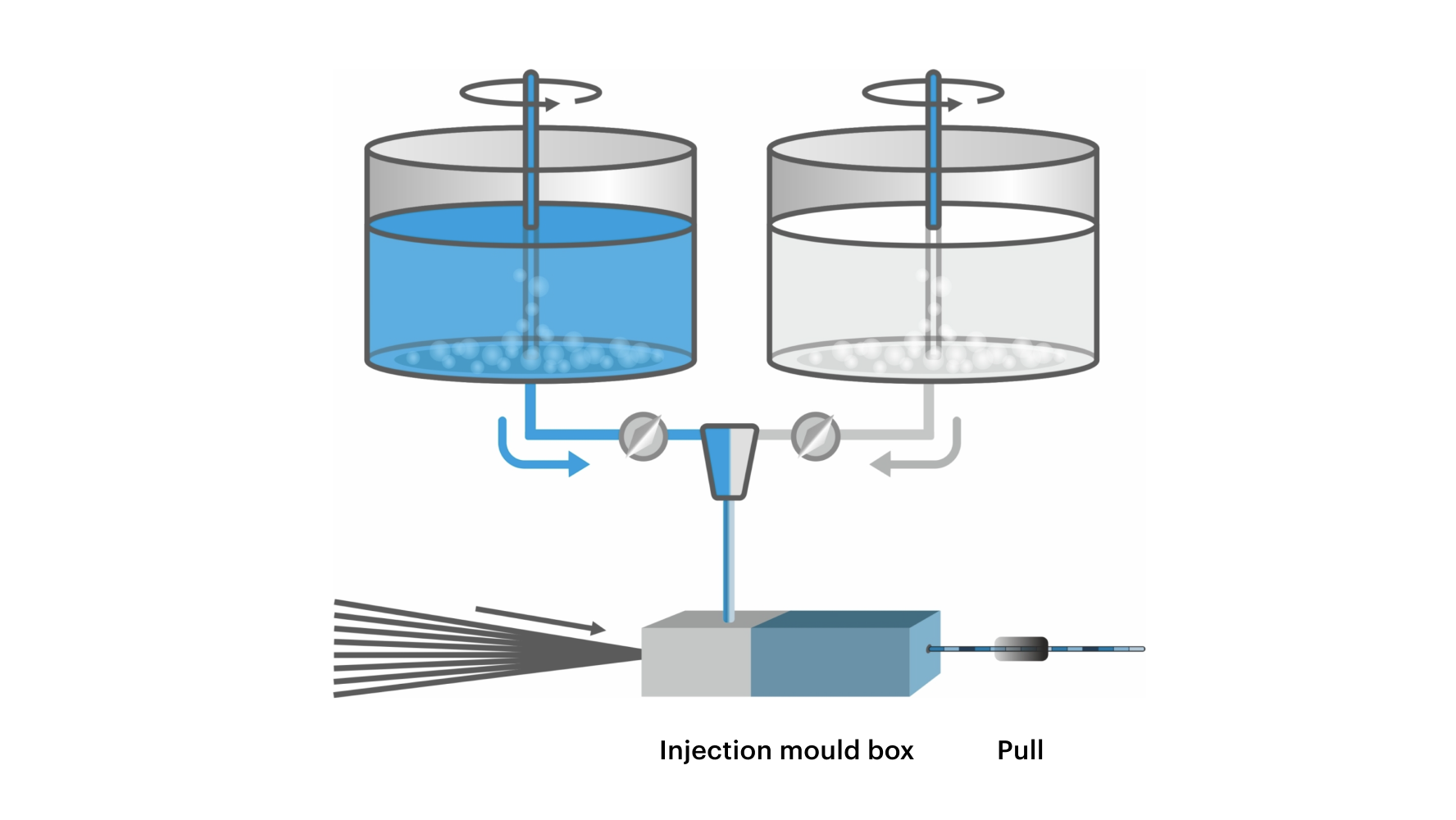

Pultrusion |

Hand layup |

Easy to apply

TUBALL™ MATRIX anti-static masterbatches can be processed with standard equipment that is widely used in the coatings industry:

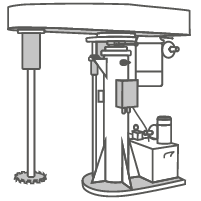

Standard single-shaft high-speed mixer

25 min total dilution time

Instant quality control with a grindometer to reach particle size ≤ 15 µm

Other benefits provided by TUBALL™ nanotubes for thermoset fiberglass composites:

- Limited impact on viscosity

- Easy to apply and the low dosage makes the logistics less complex and more efficient

- Conductivity without insulation “hot spots”

For solvent-free and solvent-based polyester and vinyl-ester systems

For solvent-free epoxy systems

Special case

Anti-static filament-winding applications:

Simplified production process

Compared with carbon veil or roving, TUBALL™ nanotubes require lower labor costs and allow conductive pipes and tanks to be produced using the same process as for non-conductive applications. There are thus additional cost savings for producers.

Application cases

GFRP Pipes

Fiberglass Tank

SMC Composite

Pay close attention to the processing guidelines for TUBALL™ MATRIX

Download PDF version:

Video instructions for use:

TUBALL™ MATRIX - Processing guidelines

How to increase rotation speed and safety, and reduce the weight of printing cylinders?

Additional information

Learn more about conductive tooling gelcoat

Conductive gelcoats for safe and efficient fiberglass molds

New generation of conductive UP and EP formulations (Elmar Greiff, BÜFA Composite Systems)

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample.