Anti-static agent for ESD-safe natural butadiene rubber (NBR) latex with retained durability and color

TUBALL™ graphene nanotubes are the most effective anti-static agent for Nitrile Butadiene Rubber (NBR) latex, which impart permanent, humidity-independent anti-static properties, effectively protecting final products from the risk of electrostatic discharge (ESD) occurring.

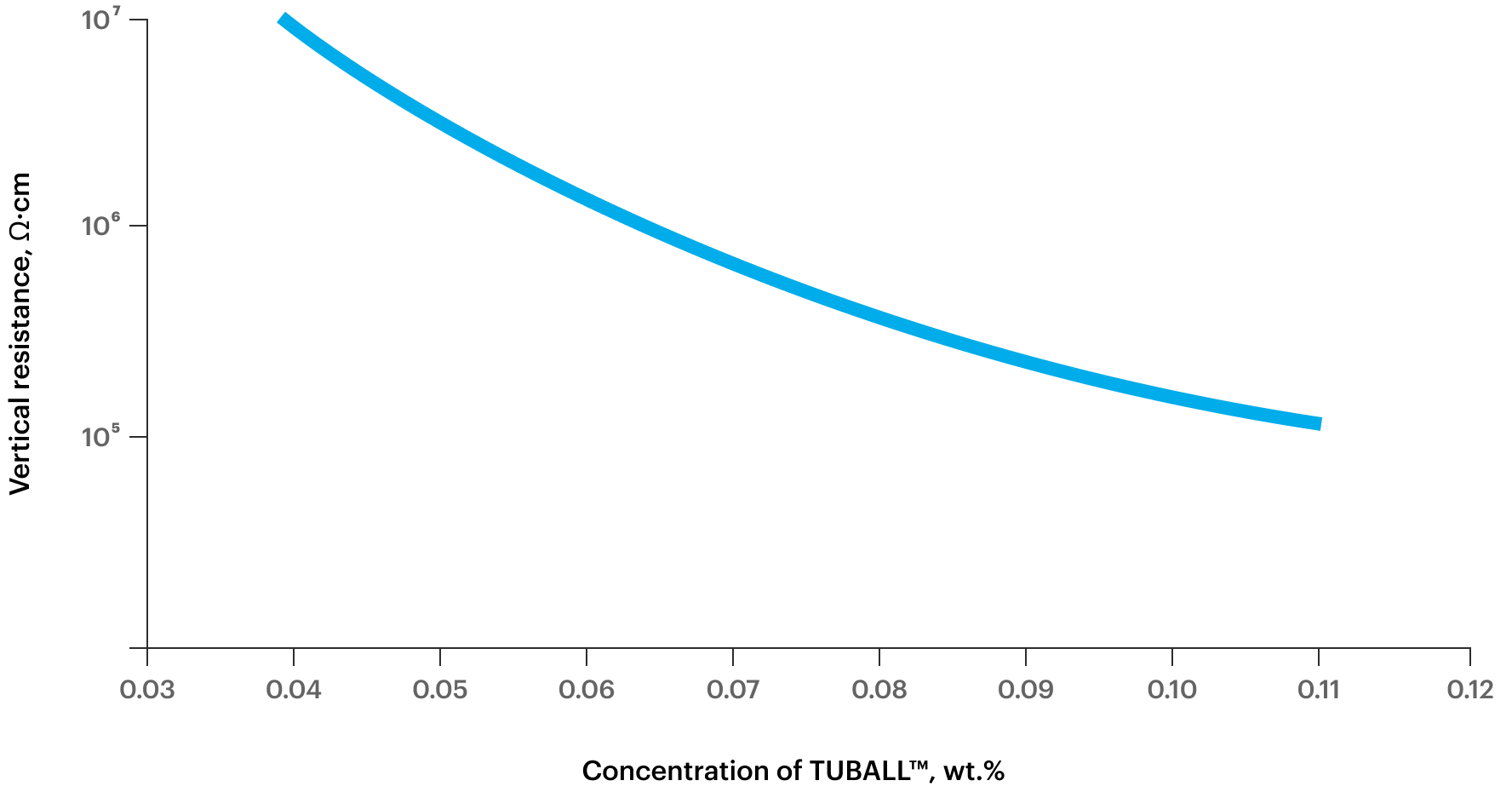

In contrast to other anti-static agents, such as multi wall carbon nanotubes, carbon fibers, and most types of carbon black, graphene nanotubes have the unique capability to form conductive networks in latexes, even with only an ultra-low concentration of TUBALL™. This is possible thanks to a high length-to-diameter ratio, together with the high conductivity, strength, and flexibility of graphene nanotubes. As a result, TUBALL™ nanotubes provide superior conductivity at significantly reduced loading levels, while retaining the mechanical properties and color of NBR latex.

Tested in NBR latex glove formulation using TUBALL™ LATEX

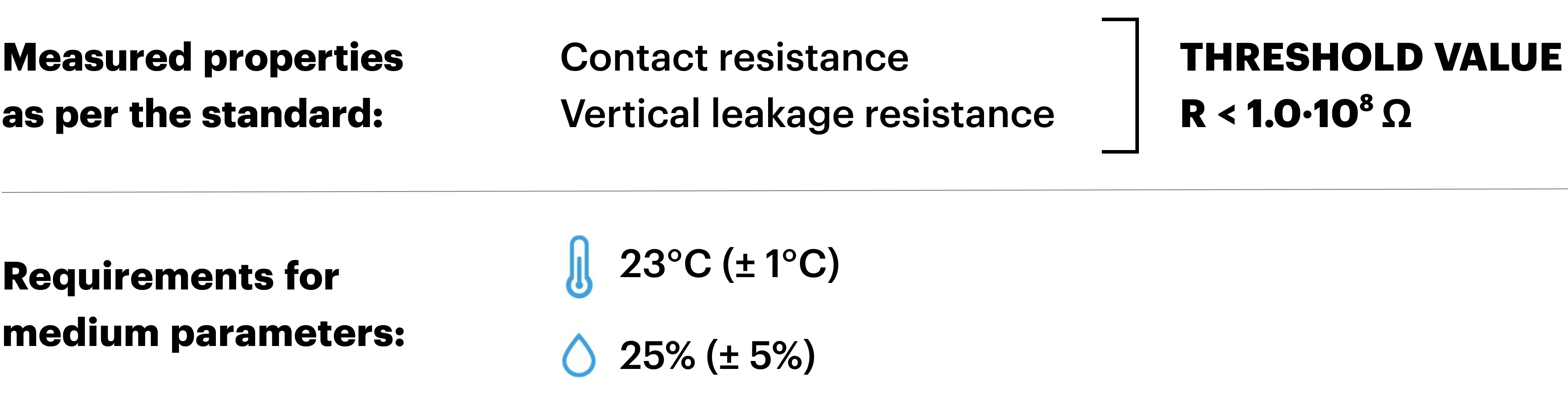

For ease of processing, OCSiAl has developed TUBALL™ LATEX, which is a ready-to-use product in the form of a water-born suspension containing a small amount of pre-dispersed graphene nanotubes. TUBALL™ LATEX provides ESD protection for NBR latex, with 108 Ω of electrical resistance level, for the production of high-quality protective equipment and gloves that are fully compliant with the EN 16350 standard.

EN 16350 standard for safety wear

Graphene nanotubes for NBR latex feature:

- No need to change standard production processes

- Allow coloration

- Maintain or improve mechanical properties

- Permanent, stable electrical resistance of < 108

Ω - Materials are ready to use “as produced”

For details on TUBALL™ LATEX, click the product card below or contact us.

TUBALL™ for silicones and latexes

| Product | Carrier | Composition | Target systems | |||||

|---|---|---|---|---|---|---|---|---|

| LSR | HCR | RTV | PSA (silicone) | NR latex | NBR latex | |||

| TUBALL™ MATRIX concentrates (Black flakes paste @ standard dosage 0.4%–10%) | ||||||||

| Plasticizer | Polydimethylsiloxane | ||||||

| Plasticizer | Siloxanes and silicones vinyl group-terminated | ||||||

| Plasticizer | Siloxanes and silicones vinyl group-terminated | ||||||

| Plasticizer | Polydimethylsiloxane + zinc chloride (CAS-No. 7646-85-7) + zinc oxide (CAS-No. 1314-13-2) | ||||||

| Plasticizer | Dimethyl, methylvinyl siloxane | ||||||

| TUBALL™-based suspensions (Black liquid @ standard dosage 0.05–0.1 % of active content in latex) | ||||||||

| Water + anionic surfactant | Water + anionic surfactant (sodium salt of polynaphthalene sulphonic acid) | ||||||

Related products

Related videos

TUBALL™ LATEX - Processing Guidelines

ESD Colored Latex Gloves - New Standard

Contact us to discuss your project specifications or to request a TUBALL™ LATEX sample