High-performance anti-static additive for electrically conductive rubbers

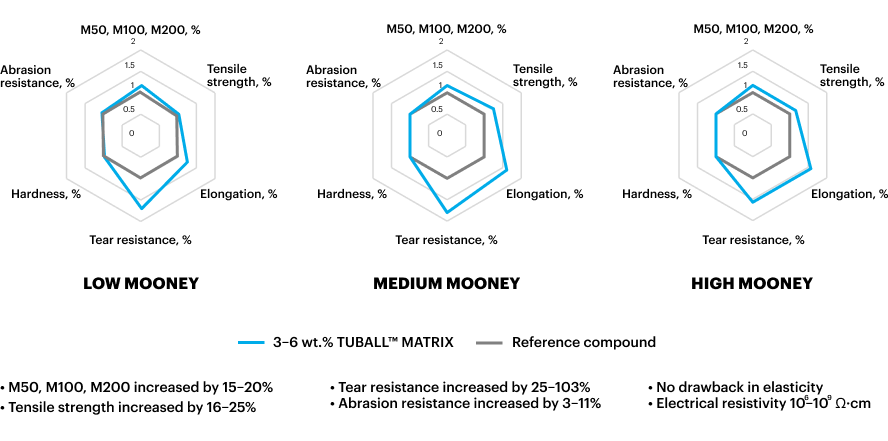

TUBALL™ graphene nanotubes are the most advanced additive for rubbers. TUBALL™ is used to impart required electrically conductive properties to rubbers and to significantly enhance their mechanical properties.

Unlike conventional additives, such as multi wall carbon nanotubes and carbon black, even a very low concentration of graphene nanotubes (single wall carbon nanotubes) creates a uniform conductive and reinforcing network inside elastomers. This allows manufacturers to avoid the drawbacks associated with previously used additives, such as impairment of mechanical properties and carbon release to the material’s surface, and also allows the production of colored conductive rubbers, if required.

TUBALL™ for rubbers

| Product | Carrier | Composition | Target systems | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| NR | SBR | IR | BR | EPDM | NBR | HNBR | FKM | PVC | |||

| TUBALL™ MATRIX concentrates (Black flakes paste @ standard dosage 1.5%–6%) | |||||||||||

| Polymer | Fluoroelastomer + barium sulfate (CAS-No. 7727-43-7) | |||||||||

| Polymer + plasticizer | Polymer + paraffinic mineral oil | |||||||||

| Polymer + plasticizer | Polymer + TDAE oil (distillates (petroleum), solvent refined heavy paraffinic, CAS-No. 64741-88-4) | |||||||||

| Polymer | Fluoroelastomer | |||||||||

| Polymer | Fluoroelastomer | |||||||||

| Polymer + plasticizer | Polymer + polar solvent | |||||||||

| Polymer + plasticizer | Polymer + polar solvent | |||||||||

To facilitate application of graphene nanotubes, OCSiAl has developed a series of industry-friendly concentrates, TUBALL™ MATRIX, containing pre-dispersed nanotubes. As a result, introducing nanotubes to the production process does not require the installation of any additional equipment, and allows the use of standard processing.

TUBALL™ MATRIX for rubbers features:

- Suitable for anti-static, static dissipative and conductive applications

- Extremely low loadings of nanotubes that preserve properties

- Retain mechanical properties including softness

- Maintain rheology and viscosity

- Standard processing and mixing equipment

- Enables colored ESD compounds

Ensuring long service life and stable conductive properties to crucial products and processes, nanotube-modified rubbers are widely used in the electronics, automotive and tires, oil & gas and other industries.

OCSiAl has developed a variety of products based on TUBALL™ graphene nanotubes for EPDM, NBR, SBR, blends of NR/BR, FKM and other types of rubbers.

IMPROVEMENT OF TEAR STRENGTH AND TENSILE PARAMETERS EVALUATION IN 3 VISCOSITY TYPES OF EPDM

To choose the right product for rubbers, please check the selection guide below and contact us to make an order or for additional information.

Related videos

Anti-static colored EPDM rubbers - Processing guidelines

Conductive elastomers: Prevent negative trade-offs in mechanical properties and color due to SWCNT

Contact us to discuss your project specifications or to request a sample