High-performance anti-static additive for electrically conductive and reinforced styrene-butadiene rubber (SBR)

TUBALL™ graphene nanotubes (SWCNTs) are a high-performance additive for styrene-butadiene rubber (SBR) compounds filled with carbon black and used in various types of tires, such as truck, agricultural and others. Nanotubes enhance the physical and mechanical properties of SBR and impart the required electrical conductivity to rubbers.

Thanks to a number of unique properties, such as high strength, conductivity, flexibility, and record length-to-diameter ratio, introducing graphene nanotubes into SBR compounds provides significant benefits in mechanical performance that could not previously be achieved.

For industry users’ convenience, OCSiAl has developed TUBALL™ MATRIX concentrate containing pre-dispersed nanotubes, which is suitable for SBR formulations filled with carbon black. It does not require any changes in standard technological procedures but makes it possible to gain a competitive edge in a rubber’s performance. Adding as little as 1.8 wt.% of TUBALL™ MATRIX leads to significant benefits in modulus, tear strength, and electrical conductivity without a negative impact on hysteresis or any other property.

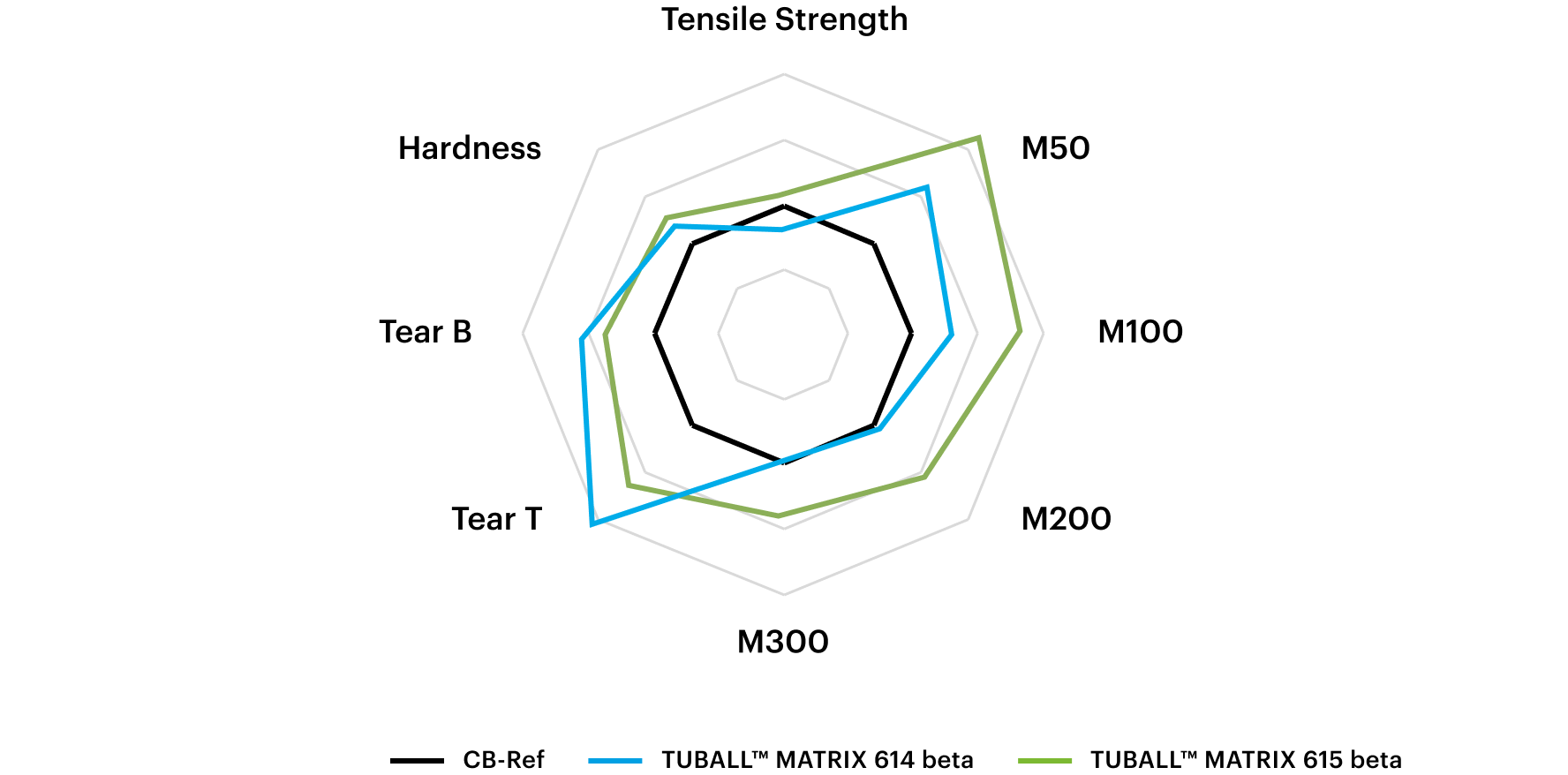

GRAPHENE NANOTUBES IMPACT ON MECHANICAL PROPERTIES OF SBR

With 1.8 wt.% of TUBALL™ MATRIX

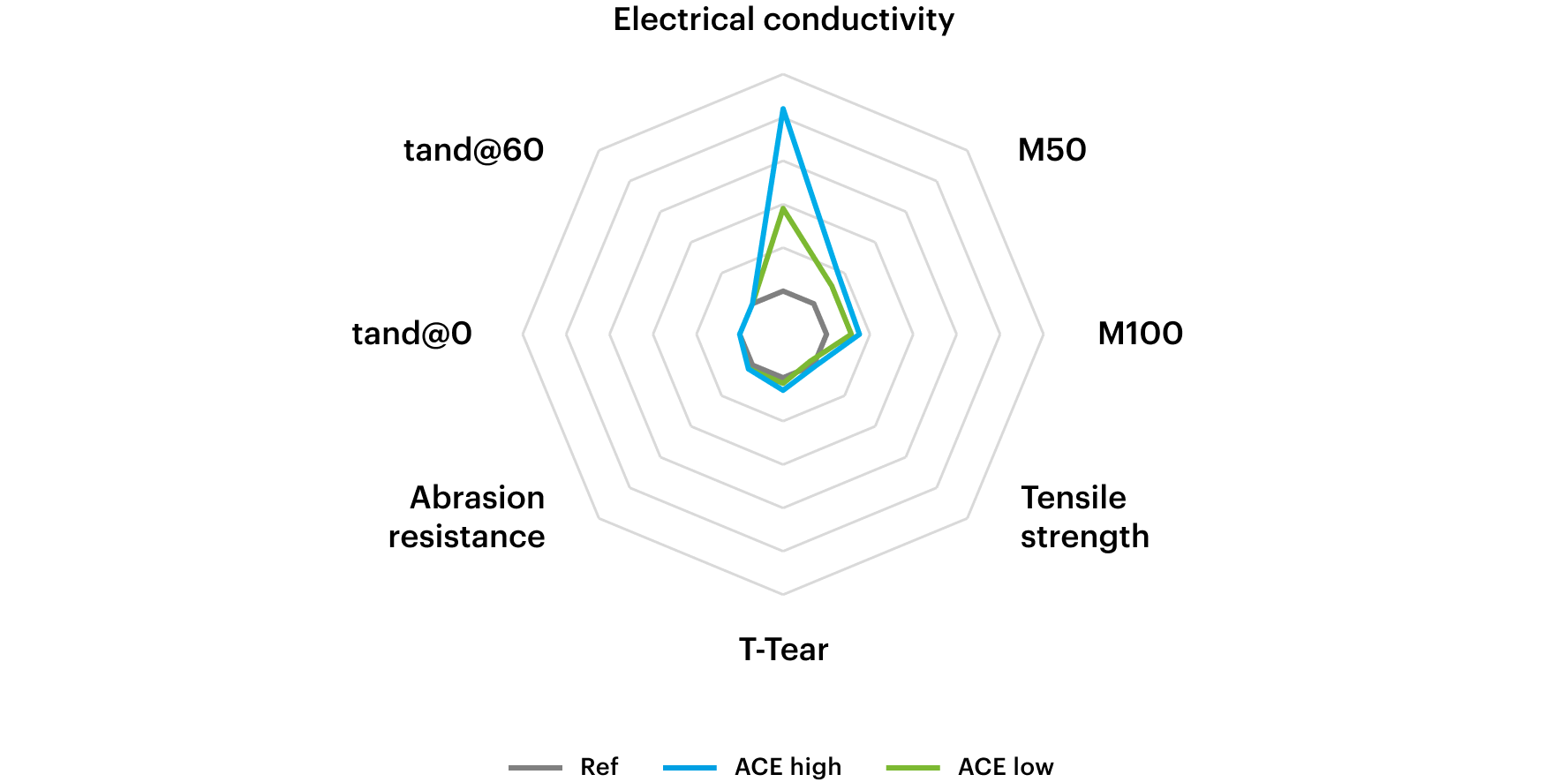

GRAPHENE NANOTUBES IMPACT TO SBR CARBON BLACK COMPOUND

With 1.8 wt.% of TUBALL™ MATRIX

Nanotube-modified SBR is the best choice for truck, industrial, and passenger vehicle tires based on carbon black, providing increased service life, stability, and uniform conductivity.

TUBALL™ MATRIX features for SBR carbon black-based compounds:

- Preserved dynamic, elastic, and technological properties

- Improved mechanical properties: tensile modulus increased by up to 70%, tear strength increased by up to 60%, abrasion resistance increased by up to 20%

- Permanent electrical conductivity

- Carrier compatible with a wide range of SBR grades

- Standard processing and mixing equipment

To find out details on nanotube-based products available for SBR compounds, please check out the selection guide below and contact us for assistance in ordering the right product.

TUBALL™ for rubbers

| Product | Carrier | Composition | Target systems | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| NR | SBR | IR | BR | EPDM | NBR | HNBR | FKM | PVC | |||

| TUBALL™ MATRIX concentrates (Black flakes paste @ standard dosage 1.5%–6%) | |||||||||||

| Polymer | Fluoroelastomer + barium sulfate (CAS-No. 7727-43-7) | |||||||||

| Polymer + plasticizer | Polymer + paraffinic mineral oil | |||||||||

| Polymer + plasticizer | Polymer + TDAE oil (distillates (petroleum), solvent refined heavy paraffinic, CAS-No. 64741-88-4) | |||||||||

| Polymer | Fluoroelastomer | |||||||||

| Polymer | Fluoroelastomer | |||||||||

| Polymer + plasticizer | Polymer + polar solvent | |||||||||

| Polymer + plasticizer | Polymer + polar solvent | |||||||||

Related videos

Graphene nanotubes in tires: going beyond existing trade-offs (Jean-Nicolas Helt, OCSiAl)

How can you avoid carbon dust at compounding plants?

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample