Carbon nanotube powder: production, properties, utilization, applications

Carbon nanotube powder (CNT powder) refers to a fine, powdered form of carbon nanotubes (CNTs). Carbon nanotubes are cylindrical structures composed of carbon atoms arranged in a hexagonal lattice. They can be single-walled carbon nanotubes (SWCNT/SWNT) or multi-walled carbon nanotubes (MWCNT/MWNT). The powder form of carbon nanotubes consists of a large number of individual nanotubes, which are typically entangled or aggregated together.

How is CNT powder manufactured?

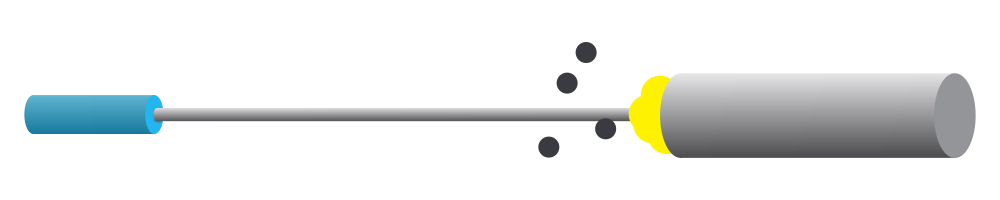

There are three main ways to produce this product: arc discharge, laser ablation of graphite, and chemical vapor deposition (CVD). All three methods require the use of metals (e.g., iron, cobalt, nickel) as catalysts.2 In the first two processes, graphite is combusted electrically or by means of a laser, and the CNTs that develop in the gaseous phase are separated.

.png)

- plasma arc discharge: production of carbon nanotubes in an arc discharge plasma in a helium atmosphere

- laser evaporation (pulsed laser ablation): evaporation of a graphite target in a high-temperature reaction by the action of a puled laser

- chemical vapor deposition (CVD): catalytic (nickel, cobalt, iron or their combinations) deposition of carbon from hydrocarbons (methane, ethylene, acetylene)

The most common method is CVD, where carbon-containing gases are decomposed on a catalyst to form nanotubes. Here is a general overview of the CNT powder manufacturing process:

-

CVD synthesis

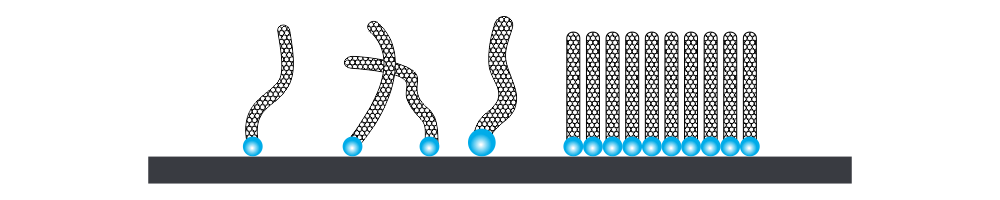

The catalyst-coated substrate is placed inside a unit chamber, and the CVD process is initiated. The chamber is typically maintained at high temperatures (around 500–1,000°C) and a carbon-containing gas is introduced.1 The most commonly used method is thermal decomposition of the carbon feedstock, where the carbon atoms from the gas decompose on the catalyst surface. Carbon atoms from the feedstock react with the catalyst, leading to the growth of carbon nanotubes. The CNTs grow vertically from the catalyst particles, forming a forest-like structure. However, this method has its drawbacks, including limited synthesis volume and high costs. As a solution, OCSiAl has developed and patented a pioneering advanced method for producing catalytic metal nanoparticles. In this method, CNTs are produced within the gas phase of synthesis while being suspended inside the chamber of the unit, allowing a production capacity in the flow unit of several kilograms per hour.3 This cost-effective technology makes it possible to offer the market TUBALLTM nanotubes at a significantly lower price than their counterparts. CNT powder collection

After synthesis, the CNTs are typically collected from the substrate. Various methods can be used for this purpose, including scraping, mechanical agitation, ultrasonication, filtration, or centrifugation.4CNT powder purification

For many applications, residual iron nanoparticles do not pose a problem, but for some it is very undesirable. In this case, CNT powder purification is applied. The collected CNT material undergoes purification steps to remove catalyst residues, amorphous carbon, and other impurities. Common purification methods include acid treatment, thermal oxidation, chemical functionalization, and electric chemical purification.5 Post-processing techniques such as milling or grinding can be employed to break up agglomerates and obtain a fine powder.6CNT powder quality control

The CNT powder is analyzed and characterized to assess its structural, morphological, and purity properties. Techniques such as scanning electron microscopy (SEM), transmission electron microscopy (TEM), Raman spectroscopy, thermogravimetric analysis (TGA), and UV-VIS-NIR spectroscopy are commonly used for characterization.

It's important to note that variations in the manufacturing process exist, depending on the specific requirements and techniques employed by different research groups and companies.

What properties does CNT powder have?

Carbon nanotube powder possesses several key properties that make it a valuable material for various applications:

- High aspect ratio

CNTs have an extremely high aspect ratio, from 50 for MWCNTs up to 10,000 and more for SWCNTs, with lengths typically ranging from micrometers to 1 millimeter while having diameters in the nanometer scale (usually 1–2 for SWCNTs and 7–100 for MWCNTs).7 This high aspect ratio provides unique structural characteristics and enables exceptional mechanical properties such as high strength and flexibility.

- Exceptional mechanical properties

Carbon nanotubes exhibit a high tensile strength of 40–100 GPa and elastic modulus up to 3,000 GPa.8, 9, They are known to be stronger than steel while being significantly lighter in weight. These properties make CNT powder attractive for enhancing the mechanical performance of various materials and creating lightweight structures.

- Electrical conductivity

CNTs are excellent conductors of electricity, possessing high electrical conductivity.10 They can efficiently transport electrons at high current density due to their one-dimensional structure, which makes carbon nanotube powder suitable for applications in electronics, sensors, and energy devices where electrical conduction is critical. The minimum working dosage for the required conductivity of composites starts from 0.01% for SWCNTs and 0.5% for MWCNTs.

- Thermal conductivity

Carbon nanotubes have exceptionally high thermal conductivity, enabling efficient heat transfer: near κ = 3,500 Wm-1K-1 at room temperature.11 They can effectively conduct and dissipate heat, making them valuable for applications in thermal management, textiles, electronics, construction, etc.

- Large surface area

Thanks to nanotubes’ structure and physical form, CNT powder possesses a large surface area, which facilitates interactions with other materials and enhances surface-based phenomena.12 This property is advantageous for applications such as energy storage devices, catalyst supports, and adsorption-based systems.

- Optical properties

Depending on their structure and chirality, carbon nanotubes can exhibit unique optical properties, including absorption, emission, and light scattering.13 These optical properties have potential applications in optoelectronics, photovoltaics, and sensing technologies.

It's important to note that the properties of CNT powder can vary depending on factors such as the synthesis method, purity, length, diameter, chirality, and functionalization of the nanotubes. These properties can be tailored through specific manufacturing and post-processing techniques to meet the requirements of various applications.

How to use carbon nanotube powder

To grant valuable properties to materials, CNT powder should be dispersed using a chemical combination of surfactants along with ultrasonic vibration. To simplify its integration into a wide range of materials and systems, OCSiAl, a leading manufacturer of SWCNTs, developed a line of pre-dispersed concentrates to provide superior electrical conductivity to various materials, while retaining and even enhancing mechanical properties, and with minimal impact on the host matrix. A distinguishing feature of these concentrates is the simplicity of their incorporation into standard production processes during the mixing phase. For instance, TUBALLTM BATT is an ultrafine dispersion of graphene nanotubes within liquid carriers, offering a readily applicable solution tailored for high-energy anodes and cathodes. This innovation bolsters battery energy density and durability. Additionally, the TUBALLTM MATRIX line of nanotube concentrates was specially designed to provide superior electrical conductivity and enhance the mechanical properties of various elastomers, thermosets, and thermoplastics.

Where can CNT powder be used?

Carbon nanotube powder can be used in a variety of applications depending on the required properties. Here are some most common applications of CNT powder:

- Energy storage devices enhanced with CNT powder

CNT powder is being rapidly adopted in the development of a new generation of batteries, supercapacitors, and fuel cells. It can be incorporated into the electrode materials (cathode and anode) to improve conductivity, increase surface area, and enhance charge storage capacity. CNTs form durable electrical networks among active material particles, enhancing battery attributes like cycle life, DCR reduction, C-rate performance, and particle cohesion.

- CNT powder-modified coatings

CNT powder imparts permanent, uniform conductivity without compromising the mechanical properties or colors of various industrial coatings. It can be incorporated into powder coatings, tank linings, various flooring systems, automotive primers, and gelcoats to provide them with anti-static properties and added functionality.

- Composites with CNT powder

CNT powder can be used inside polymer matrices, glass fiber filled plastics, and carbon fiber filled plastics to create a 3D reinforcing network inside materials, enhancing their electrical properties. Popular applications include pipes and tanks for the oil and gas industry, gratings and cable trays for ESD-sensitive areas, gas cylinders for firefighters and medical applications, and printing sleeves.

- CNT powder in sensors

CNT powder can be employed in the fabrication of sensors for various applications. The powder can be integrated into sensor platforms to enhance sensitivity, selectivity, and response time. CNT-based sensors are used in gas sensing, biosensing, strain sensing, and other applications.

- Textiles containing CNT powder

The incorporation of CNT powder into textile materials has enabled the introduction of multifunctionality to textiles used across different industries, including medical fabrics, protective workwear, automotive textiles, smart textiles, and construction heating fabrics. The presence of nanotubes imparts desirable electrical conductivity to these textiles, thereby providing them with valuable functionalities.

- Additive manufacturing using CNT powder

CNT powder can be used in additive manufacturing techniques such as 3D printing. The powder is mixed with a suitable printing medium or used as a filler material in the printing process.14 This allows for the creation of complex structures with enhanced mechanical and electrical properties.

Above all, the application of CNT powder in electronics, encompassing microprocessors and solar cells, has garnered significant traction in research facilities, progressively nearing practical implementation.

CNT powder is widely used in research and development activities, serving as a versatile starting material for the synthesis of other CNT-based materials. Researchers can functionalize, modify, or further process the powder to create tailored CNT structures for novel applications. The exceptional properties of CNT powder make it a versatile additive able to modify most of materials.

Synthesis Methods of Carbon Nanotubes and Related Materials: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC5445923/

Carbon nanotubes—what they are, how they are made, what they are used for: https://www.nanowerk.com/nanotechnology/introduction/introduction_to_nanotechnology_22.php

New perspectives in SWCNT applications: Tuball SWCNTs. Part 1. Tuball by itself—All you need to know about it: https://www.sciencedirect.com/science/article/pii/S2667056922000311?via%3Dihub

Ibid.

Synthesis and Purification of Carbon Nanotubes: https://www.intechopen.com/chapters/77073

A review of purification techniques for carbon nanotubes: https://www.researchgate.net/publication/244668507_A_review_of_purification_techniques_for_carbon_nanotubes

Single-walled carbon nanotubes: structure, properties, applications, and health & safety: https://tuball.com/articles/single-walled-carbon-nanotubes

Mechanical properties of carbon nanotubes and its applications—a review: https://www.irjet.net/archives/V8/i8/IRJET-V8I8118.pdf

Electronic and Mechanical Properties of Carbon Nanotubes: https://link.springer.com/chapter/10.1007/0-306-47098-5_22

Electrical properties of nanotubes: https://www.understandingnano.com/electrical-properties-carbon-nanotubes.html

Thermal conductance of an individual single-wall carbon nanotube above room temperature: https://pubs.acs.org/doi/10.1021/nl052145f

Properties that Influence the Specific Surface Areas of Carbon Nanotubes and Nanofibers: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4643664/#:~:text=CNTs%20have%20large%20surface%20areas,et%20al.%2C%202001).

Carbon Nanotube Optics and Their Uses: https://www.azooptics.com/Article.aspx?ArticleID=1507

-

Carbon Nanotubes and Graphene as Additives in 3D Printing: https://scholarworks.umass.edu/cgi/viewcontent.cgi?article=2714&context=chem_faculty_pubs