Electrically conductive rubbers with graphene nanotubes: durability, elasticity, and color, with low hardness and no carbon release

TUBALL™ graphene nanotubes, also known as single wall carbon nanotubes, have an effect even at ultra-low dosages starting from just 0.15 wt.% for anti-static, static dissipative and conductive rubber applications.

Examples of applications

Tapis roulants et rouleaux en skept

Tapis roulants industriels de NBR

Pneu plein non marquant

In contrast to other conductive agents, graphene nanotubes are a versatile conductive agent offering good performance in all key parameters.

.png)

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

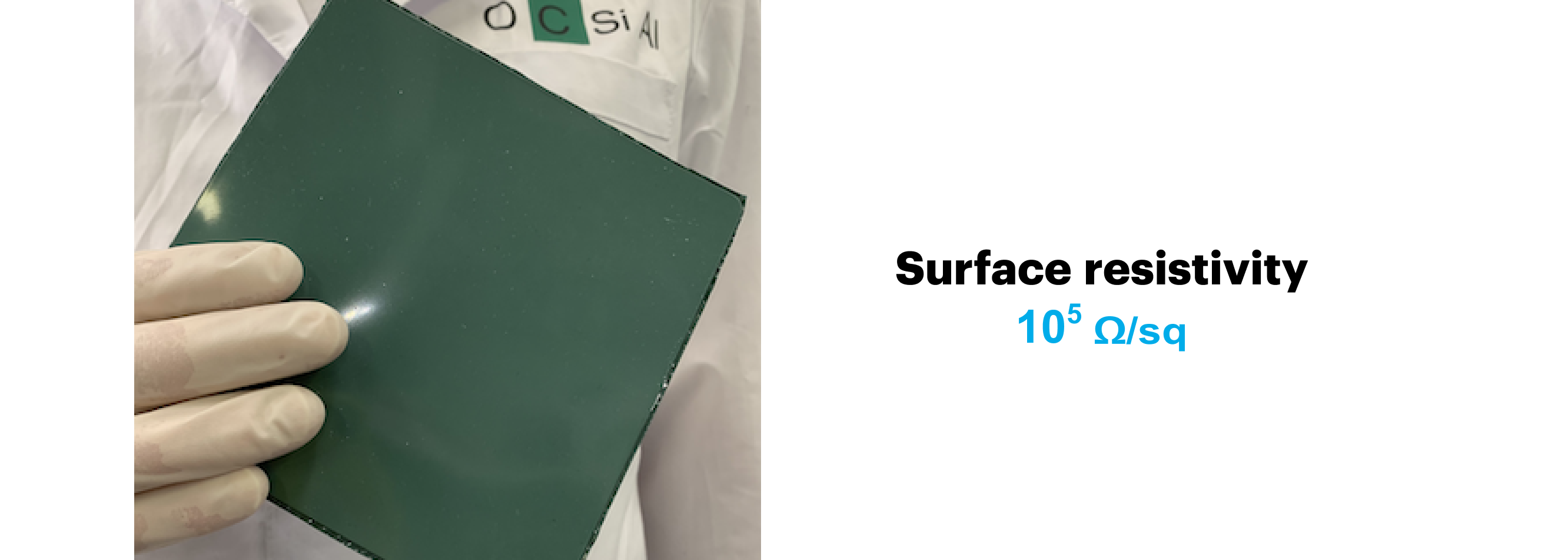

Сolored anti-static compounds without carbon release to surface

The wide range of color options makes it possible to provide various parts to the market where anti-static properties are required.

EPDM-based rubber with 6 wt.% of TUBALL™ MATRIX 610 and green pigment

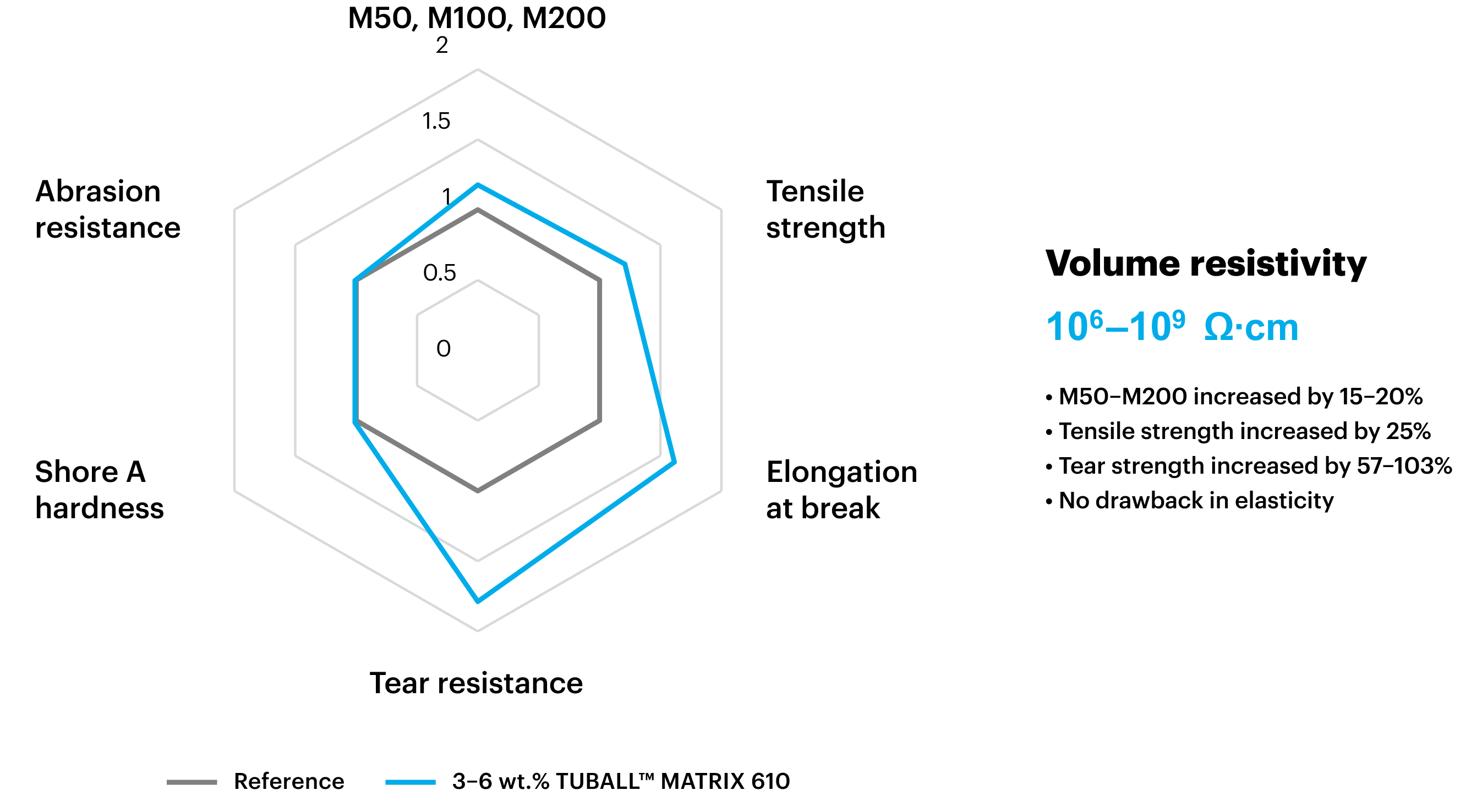

Improved mechanical properties

TUBALL™ nanotubes, in contrast to traditional conductive agents, minimize the impact on compound elasticity and on tensile parameters, viscosity and rheological properties.

The ultra-low dosage of TUBALL™ makes it possible to use full silica-based formulations and obtain the desired anti-static properties, as well as improved tear strength and tensile performance, without degradation of elastic properties and with the ability to maintain low hardness.

EPDM with graphene nanotubes

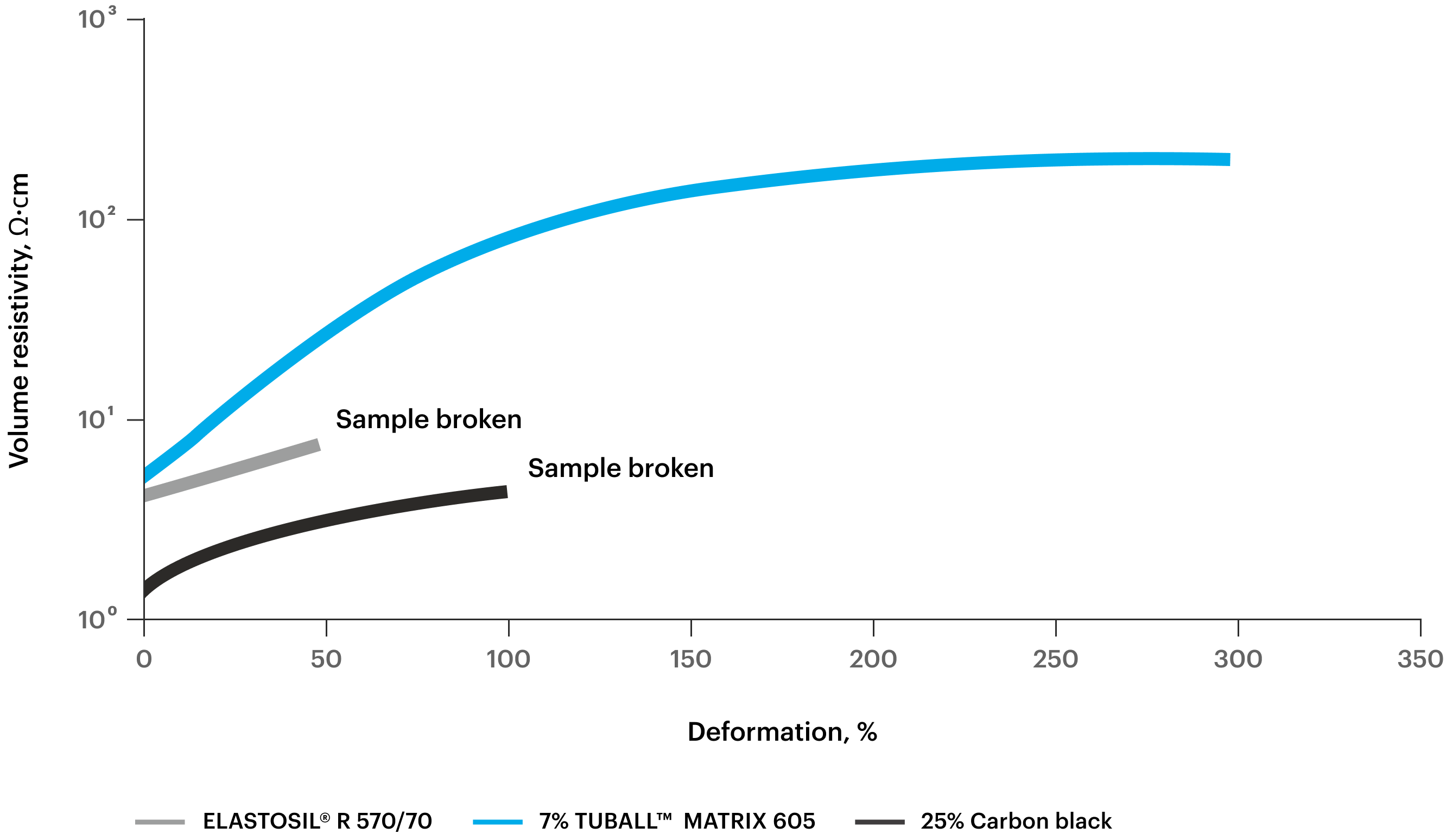

Conductive HCR: TUBALL™ nanotubes vs carbon black

Ready to use nanotube masterbatches are available for various types of rubbers:

- Anti-static EPDM with extended service life and stable conductivity

- Colored NBR with electrical conductivity and enhanced durability

- NR/BR compounds used for non-marking solid tires

- Electrically conductive silicones

- Conductive FKM

- Polyurethane systems and coatings with electrical conductivity and preserved mechanical properties

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Easy-to-apply nanotube concentrates

TUBALL™ graphene nanotubes are applied via the easy-to-use additive TUBALL™ MATRIX, which is a line of concentrates based on polymer and plasticizer carriers and pre-dispersed TUBALL™ graphene nanotubes.

TUBALL™ MATRIX can be added using standard processing and mixing equipment.

Please choose the right product for you to test, or contact us for assistance:

| Product | MATRIX 605 | MATRIX 608 beta | MATRIX 610 | MATRIX 618 beta | MATRIX 619 beta | MATRIX 620 beta | MATRIX 621 beta | MATRIX 622 beta | MATRIX 623 beta |

|---|---|---|---|---|---|---|---|---|---|

| Carrier media | Plasticizer | ||||||||

| Polymethyl-vinylsiloxane and vinyl-terminated polydimethyl-siloxane | Fluoro gum | Polymer, paraffinic oil | Synthetic ester plasticizer | Polymer, dibutyl phthalate | Polymer, TDAE oil | Fluoro gum | Fluoro gum | Polymer, polar solvent | |

| NR | |||||||||

| HCR silicone | |||||||||

| BR | |||||||||

| EPDM | |||||||||

| NBR, HNBR | |||||||||

| FKM | |||||||||

— Product available

— Validation on going

Contact us to discuss your project specifications or to request a TUBALL™ MATRIX sample

Video on conductive rubbers with TUBALL nanotubes

Ekaterina Gorbunova, OCiAl Vice-President for elastomers, talking about rubbers with TUBALL nanotubes

How to obtain conductive rubbers with graphene nanotubes - Processing guide